Coal-fired power plant flue gas efficient purification device and method

A coal-fired power plant and purification device technology, applied in the field of exhaust gas purification, can solve problems such as unreachable, chimney corrosion, serious problems, etc., achieve reasonable design, reduce the probability of being corroded, and benefit the protection of the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples will be used in conjunction with the accompanying drawings to further describe the high-efficiency purification device for flue gas in coal-fired power plants of the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

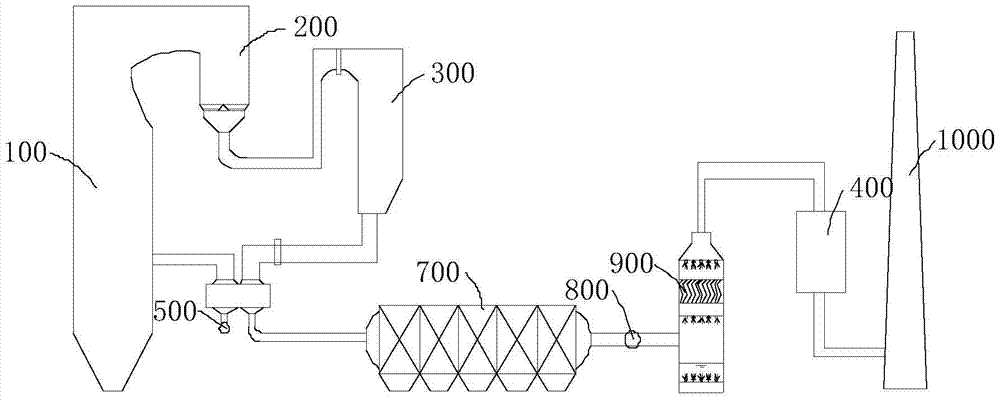

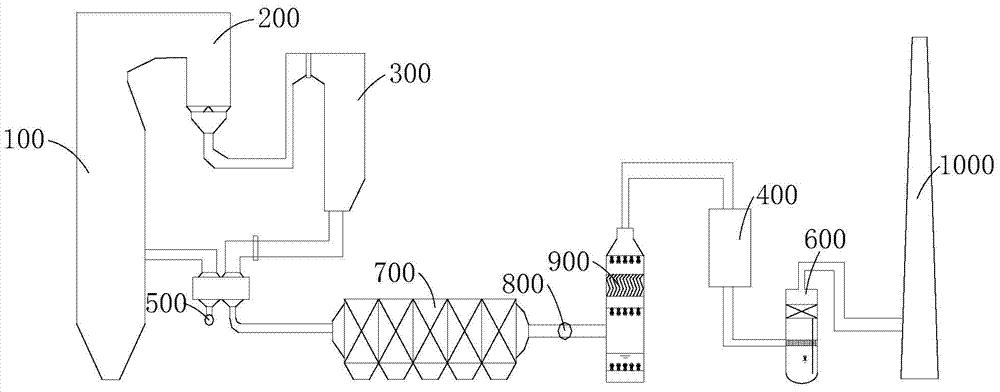

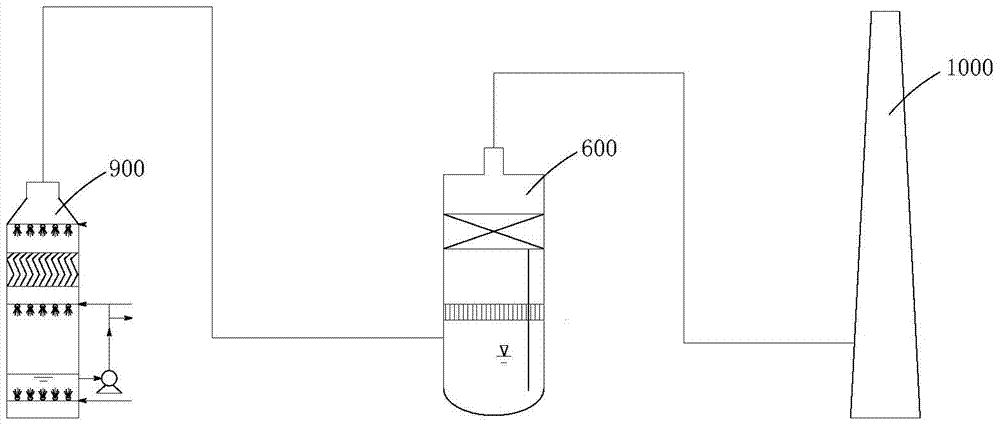

[0057] At present, due to technical reasons, the flue gas emitted by coal-fired power plants, NO x , SO x It cannot be separated from the flue gas to meet the relevant emission standards, resulting in the discharge of a large amount of harmful gases into the atmosphere, causing air pollution. Such as Figure 1-3 As shown, a coal-fired power plant flue gas efficient purification device is arranged between the boiler 100 and the chimney 1000 of the coal-fired power plant, and is used to purify the flue gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com