A gas cutting nozzle with catalytic combustion

A catalytic combustion and cutting nozzle technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of long preheating time, affecting cutting speed and cutting quality, and low flame temperature, so as to improve gas properties and improve cutting Efficiency and quality, effect of increasing flame temperature and flame propagation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

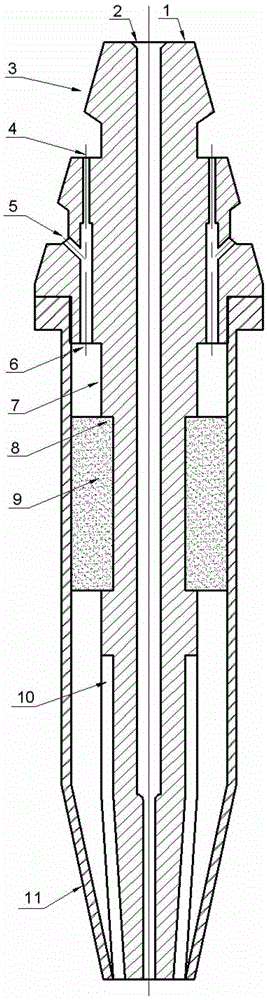

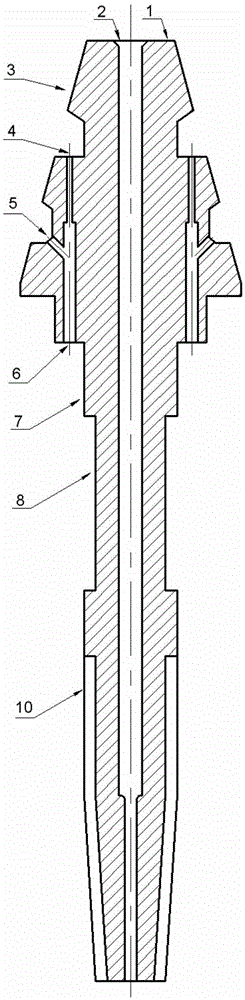

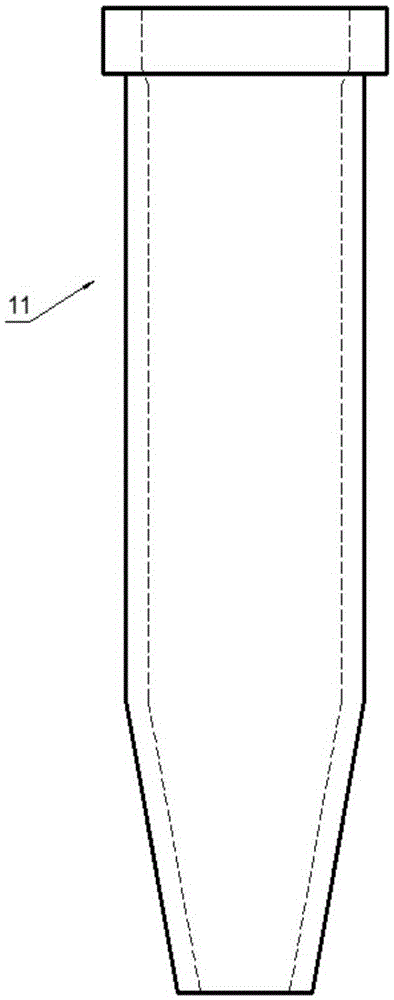

[0014] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the cutting nozzle of the present invention includes three parts, the cutting nozzle core, the cutting nozzle fairing and the catalyst bed. The cutting nozzle core is composed of a head and a body, and generally they are fixed by connecting threads. The head of the cutting nozzle core is provided with a cutting oxygen inlet hole through the body, a circle of preheating oxygen inlet hole and a circle of gas inlet hole. The preheated oxygen and gas inlet ports in the head mix at the beginning of the mixing air port below it. The body of the cutting nozzle core is provided with a groove for installing the catalyst bed. The depth of the groove is 1 to 4 mm and the length is 10 to 30 mm. The number of distribution channels is 10 to 20, and the gas is ejected from the distribution channels.

[0015] The cutting nozzle fairing is sleeved on the cutting nozzle core body, and forms an air injection channel with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com