Water collection application of porous fine-denier nylon fiber

A nylon fiber and fine denier technology is applied in the application field of porous fine denier nylon fiber for water collection, which can solve the problems of difficult to achieve large-scale seawater desalination, lack of fresh water resources, complicated operation process, etc., and achieves low comprehensive economic cost and water collection. Simple operation and low economical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 80 parts of nylon 6 slices, 20 parts of zinc sulfate, 10101 parts of antioxidant, 12 parts of antistatic agent PEG60012, and PEG200003 parts (both parts by weight) are made into additive masterbatch, and then according to the weight of additive masterbatch and nylon 6 slices The ratio is 7:1000 and melt spinning is carried out after mixing. The temperature of the melt in each zone of the screw extruder is 250°C, 270°C, 270°C and 275°C, and the spinning temperature is 250°C. The hole diameter of the spinneret used is 0.35 mm, the length is 0.7 mm, the winding speed is 1700 m / min, and the fineness of the fine-denier nylon fiber is 0.8 denier.

experiment example

[0064] The 0.8-denier nylon used in this experimental example was prepared in Example 1.

[0065] The 17-denier nylon is: Zhejiang Meisibang Chemical Fiber Co., Ltd., FDY (fully drawn yarn).

experiment example 1

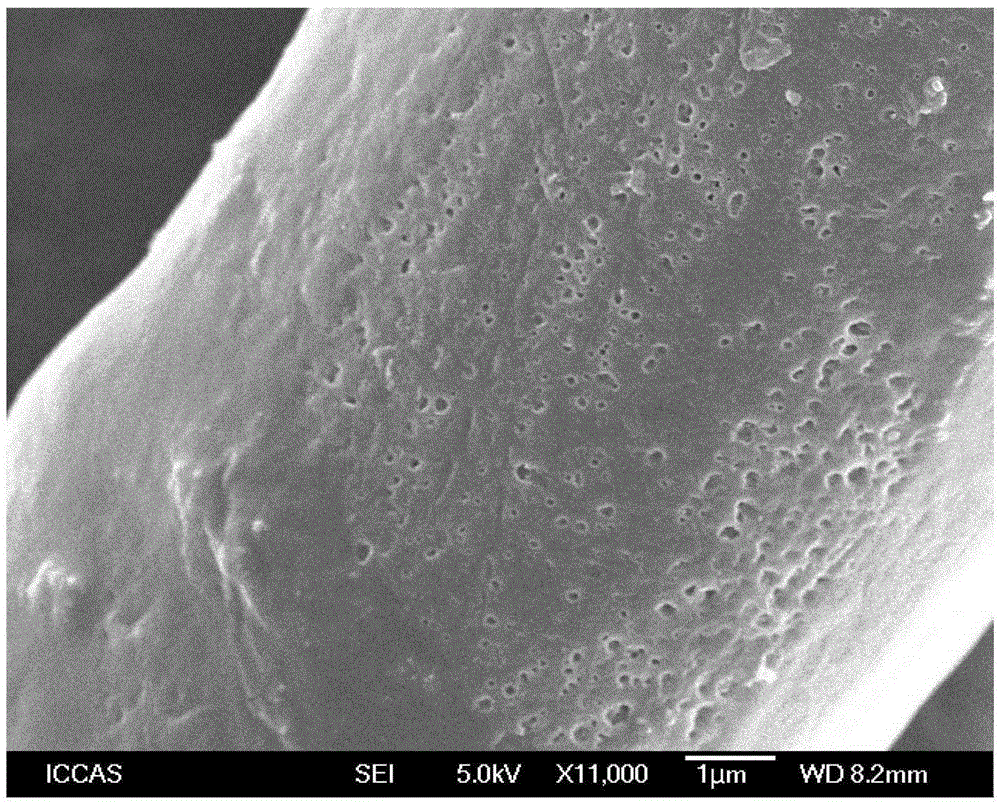

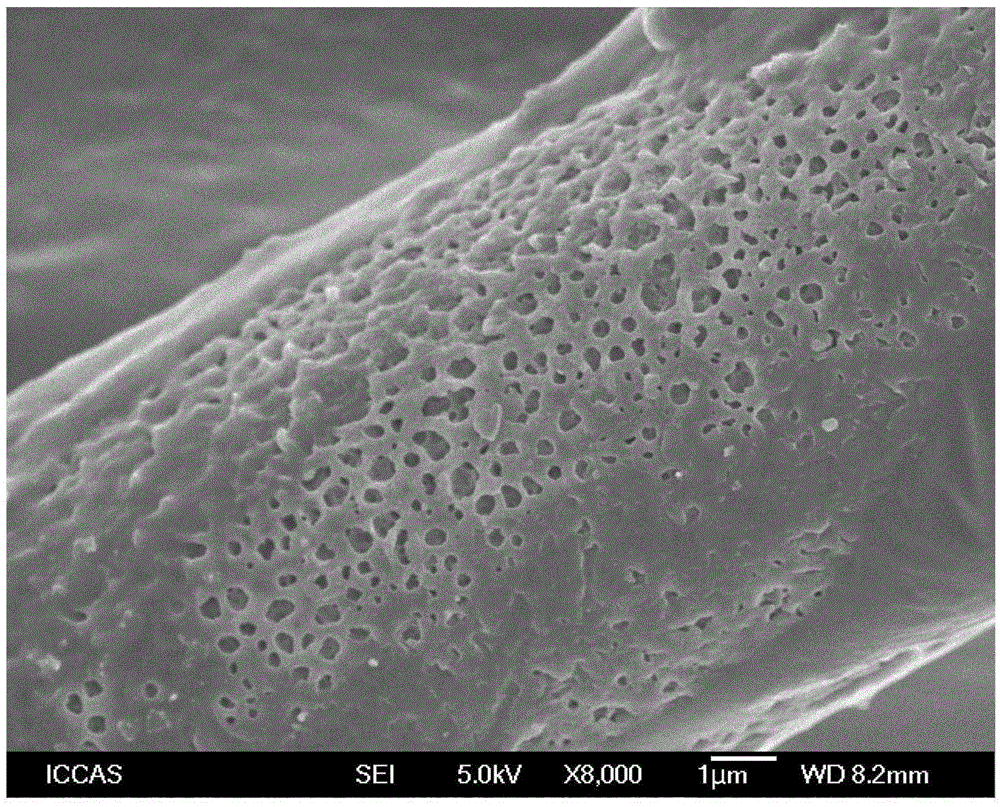

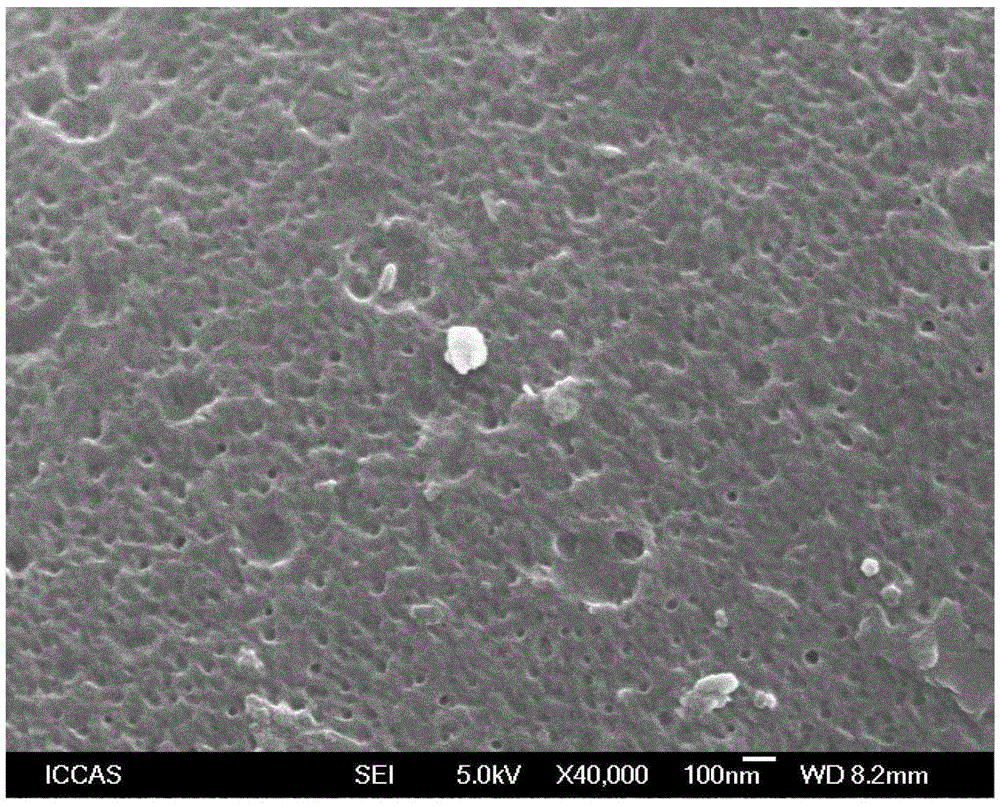

[0066] Experimental Example 1 The relationship between the richness of the porous structure of fine-denier nylon fibers and the processing time

[0067] Take 6 groups of 0.8-denier nylon 6 fibers, 1 g for each group, and use saturated CaCl 2 Solution immersion treatment, treatment for 15min, 30min, 45min, 1h, 1.5h and 2h respectively, after the treatment, the porous nylon fine denier fiber obtained by the above treatment was characterized by scanning electron microscope (SEM), the results are as follows Figure 1~6 Shown:

[0068] Depend on Figure 1~6 It can be clearly seen that the surface of nylon fiber gradually changes from dense to porous structure. The longer the treatment time, the more obvious the change becomes, and the micropores on the surface are closer to the spider silk structure, which is more conducive to water collection. However, when the treatment time After reaching 2 hours, its surface structure does not continue to change, and the water collection capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com