Marsh gas production system of marsh gas tank with drive mechanism

A driving mechanism and production system technology, which is applied in the field of biogas, can solve the problems of large space occupied by gas storage tanks, inconvenient gas collection, and impact on biogas production, and achieve the effects of low production cost, convenient manufacture, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

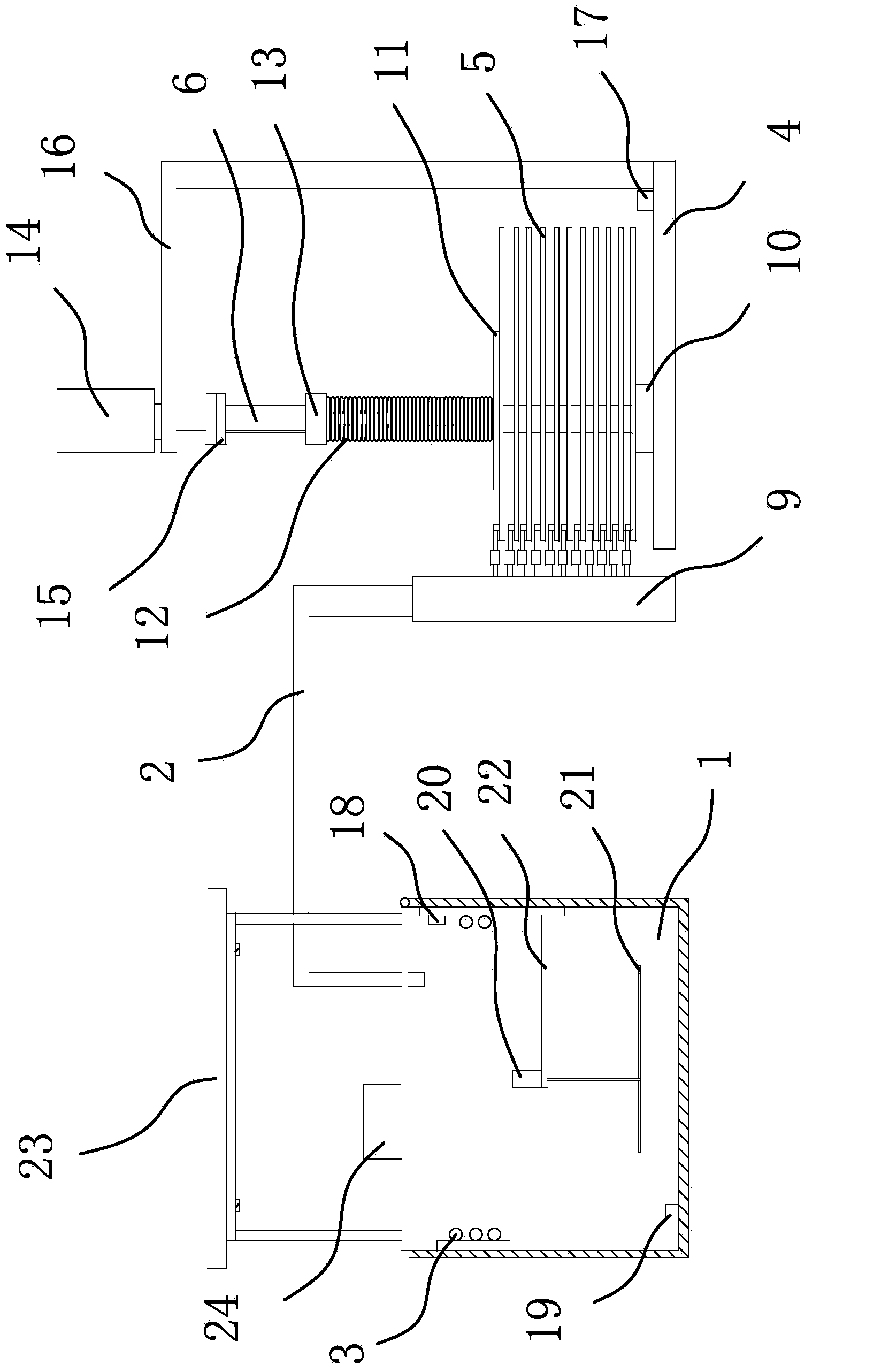

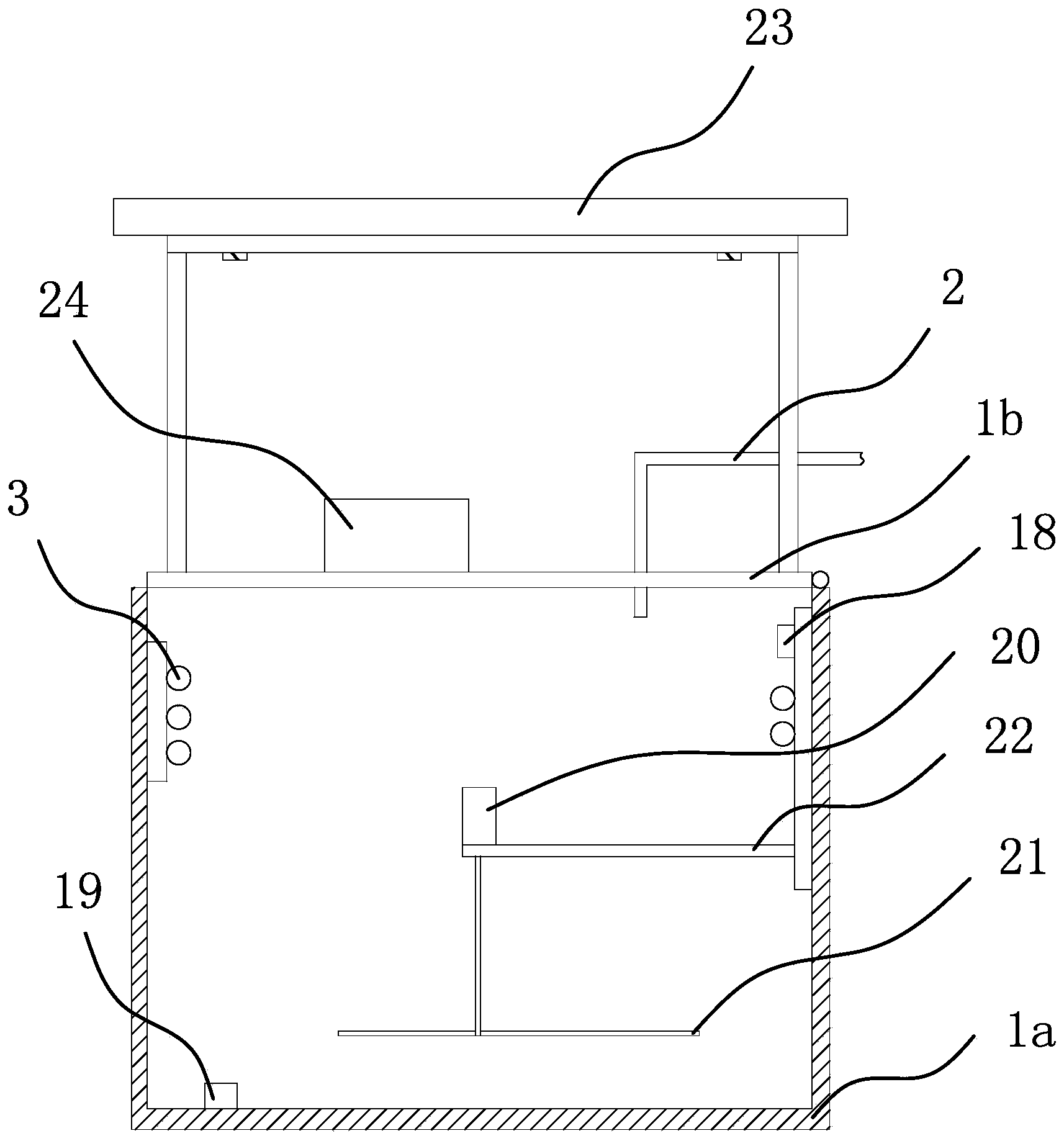

[0036] Such as figure 1 and 2 As shown, a biogas production system of a biogas digester with a driving mechanism includes a biogas digester 1, a biogas digester 1 includes a pond body 1a capable of producing biogas, a pond cover 1b hinged on the upper part of the pond body 1a and a connecting pipe 2, the pond The body 1a is provided with an electric heating tube 3, one end of the connecting tube 2 passes through the pool cover 1b and communicates with the pool body 1a, and the connecting tube 2 and the pool cover 1b are kept sealed, and the other end of the connecting tube 2 is connected with a storage device, The pool body 1a is also provided with a control mechanism that can automatically turn on the electric heating tube 3 when the temperature in the pool body 1a is lower than the set value.

[0037] Specifically, a mounting hole is opened on the pool cover 1b, and the connecting pipe 2 passes through and is fixed in the mounting hole. A sealing ring is fixed on the connec...

Embodiment 2

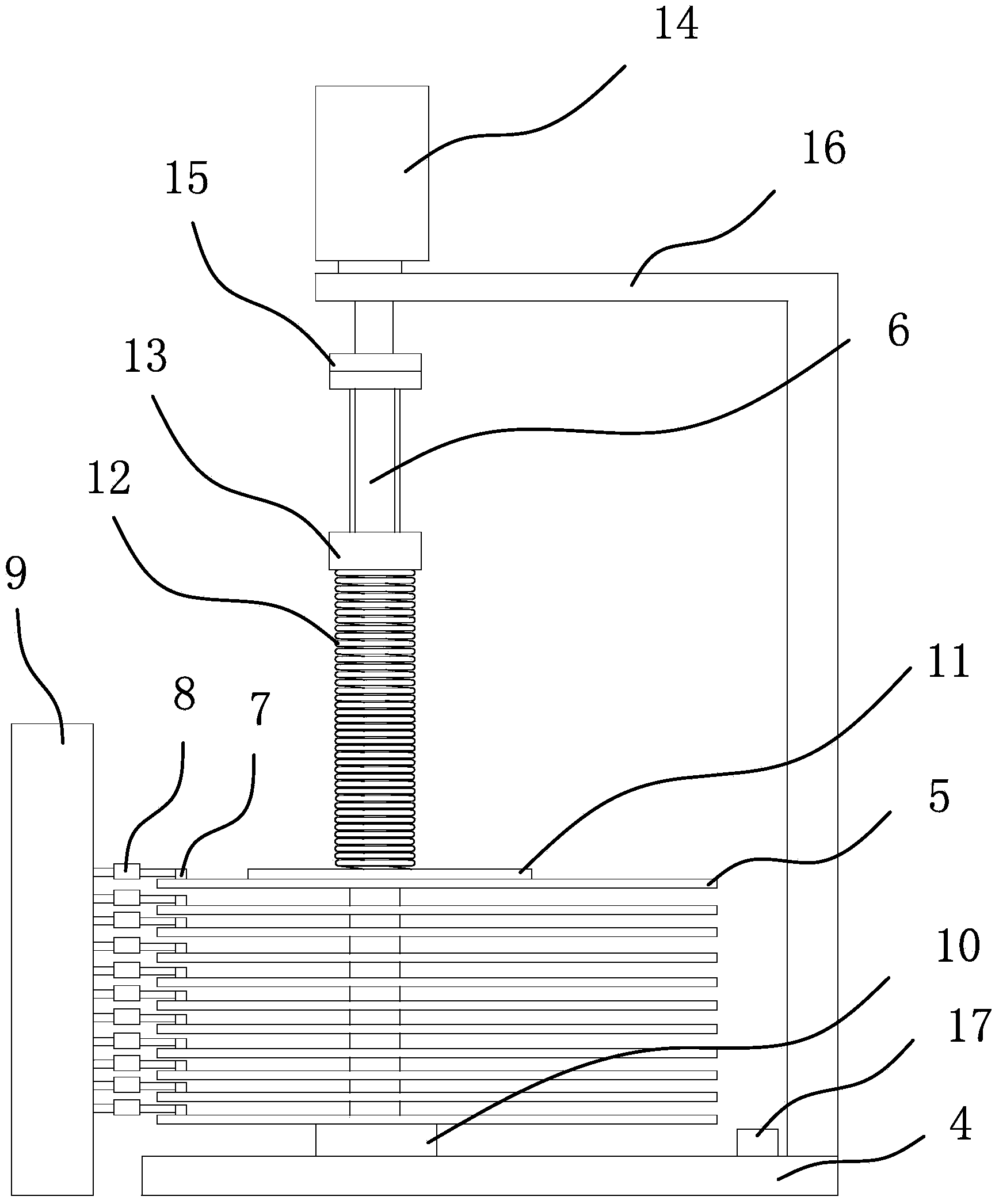

[0047] The structure and principle of this embodiment are basically the same as that of the first embodiment, the difference is that in the first embodiment, the holding mechanism includes a pressing plate 11, a spring 12 and a nut 13; while in the second embodiment, the holding mechanism It includes a nut 13 and an annular pressure plate 11 , the pressure plate 11 is sheathed on the column 6 , and the nut 13 is screwed to the upper section of the column 6 . The lower plate surface of the pressing plate 11 can always be pressed and held on the uppermost air storage bag 5 under the action of its gravity, and the pressing plate 11 can move upwards with the swelling of the air storage bag 5 at the same time. And moving downward, the volume of the air storage bag 5 is always in the minimum state, thereby reducing the occupied space of the air storage bag 5 . Nut 13 is screwed on the upper end of column 6 with hand, just can prevent that pressing plate 11 breaks away from column 6....

Embodiment 3

[0049] The structure and principle of the present embodiment are basically the same as those of the first embodiment, the difference is that in the first embodiment, the driving mechanism includes a bracket 16, a shaft coupling 15 and a motor 14; and in the third embodiment, as Figure 5As shown, the drive mechanism includes a driving gear 25, a driven gear 26, a chain 27 and a motor 14, the driving gear 25 is fixed on the output shaft of the motor 14 by a flat key, and the driven gear 26 is fixed on the upper section of the column 6 by a flat key , the chain 27 is arranged between the driving gear 25 and the driven gear 26, the motor 14 is fixed on the base 4 through a fixing plate, and the fixing plate is fixed on the base 4 by screws. By controlling the positive and negative rotation of the motor 14, the driving gear 25 can be driven to rotate forward and reverse, so that the vertical column 6 can be rotated positively and negatively through the chain 27, and finally the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com