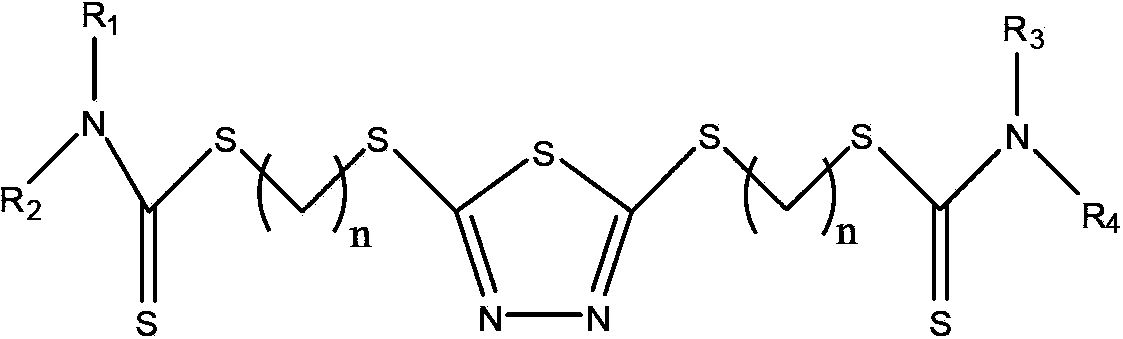

Thiocarbamate-containing thiadiazole derivative, and preparation method and use thereof

A technology containing thiocarbamate and thiadiazole derivatives, which is applied in lubricating compositions, petroleum industry, additives, etc., and can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 30.0g of 2,5-dimercapto-1,3,4-thiadiazole into 100mL of reaction medium toluene, add 8.0g of sodium hydroxide catalyst under stirring, after heating to 60°C, slowly add 152.0g of N,N' - Diisooctyldithiocarbamate ethyl chloride toluene solution, after the dropwise addition, the temperature was raised to 90°C, and the reaction was carried out for 5 hours. After cooling to room temperature, a small amount of insoluble matter was filtered off, and then washed with distilled water until neutral , evaporated to remove the solvent, and dried in vacuo to obtain a yellow oily liquid that is a thiadiazole derivative product containing thiocarbamate.

Embodiment 2

[0034] Add 15.0g of 2,5-dimercapto-1,3,4-thiadiazole into 100mL of reaction medium ethanol, add 10.1g of triethylamine catalyst under stirring, after heating to 60°C, slowly add 59.7g of N,N' - Di-n-butyldithiocarbamate methyl bromide benzene solution, after the dropwise addition, the temperature was raised to 75°C, and reacted for 4 hours. After cooling to room temperature, a small amount of insoluble matter was filtered off, and then washed with distilled water until neutral , evaporated to remove the solvent, and dried in vacuo to obtain a light yellow liquid that is a thiadiazole derivative product containing thiocarbamate.

Embodiment 3

[0036] Add 15.0g of 2,5-dimercapto-1,3,4-thiadiazole to 150mL of N,N'-dimethylformamide, add 8.4g of sodium bicarbonate catalyst under stirring, heat to 90°C, slowly Add dropwise 81.6g of N,N'-dioctyldithiocarbamate butyl chloride N,N'-dimethylformamide solution, after the dropwise addition, heat up to 155°C, react for 6 hours, and wait to cool to room temperature Finally, filter out a small amount of insoluble matter, then wash with distilled water until neutral, evaporate the solvent, and dry in vacuum to obtain a yellow liquid that is a thiadiazole derivative product containing thiocarbamate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com