High-performance ammonia recovery system

An ammonia recovery and high-efficiency technology, which is applied in ammonia preparation/separation, chemical industry, water/sludge/sewage treatment, etc., can solve problems such as low stripping efficiency, secondary pollution of the environment, and death of fish and shrimp. Effects of improving preheating efficiency and increasing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will describe embodiments of the high-efficiency ammonia recovery system based on the present invention with reference to the relevant drawings. For ease of understanding, the same components in the following embodiments are described with the same symbols.

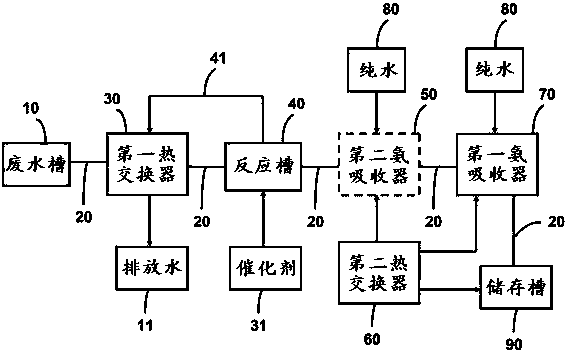

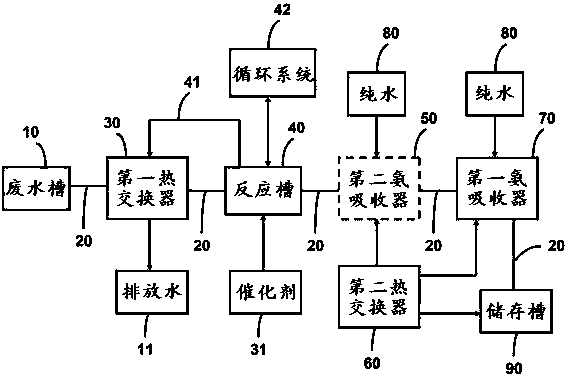

[0021] see figure 1 , figure 1 It is a block diagram of the first embodiment of the high-efficiency ammonia recovery system of the present invention. The high-efficiency ammonia recovery system of the invention is suitable for recovery of ammonia-containing waste water. The high-efficiency ammonia recovery system at least includes a first heat exchanger 30 , a reaction tank 40 and a first ammonia absorber 70 . Wherein, the first heat exchanger 30 is used for preheating the waste water in the waste water tank 10 , and the reaction tank 40 is connected to the first heat exchanger 30 through the vacuum pipeline 20 .

[0022] Wherein, the vacuum line 20 is used to drive the waste water in the waste wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com