Ceramic bioreactor and sewage treatment method thereof

A bioreactor and bioreactor technology, which is applied in the field of ceramic bioreactor and its sewage treatment, can solve the problem of reasonable coordination of porosity and strength relationship, which hinders large-scale application, unreasonable design of pre-stage biological pretreatment unit, and increase of CFBR. System investment cost and other issues, to achieve the effect of reducing maintenance and replacement costs, low pressure demand, and low hydraulic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

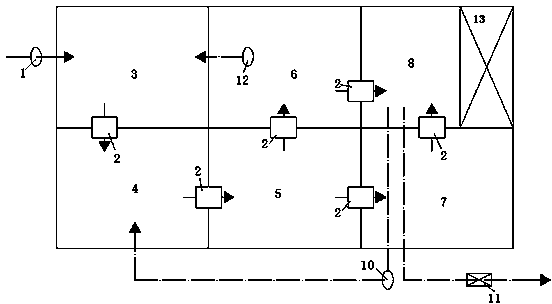

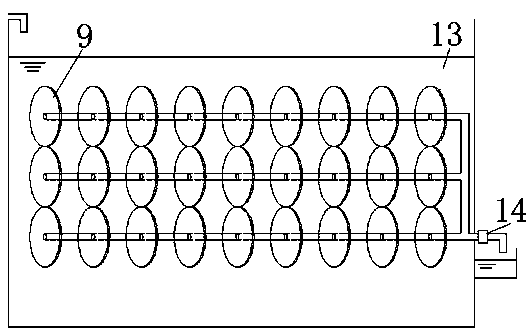

[0049] The ceramic filter bioreactor of the present invention is used for sewage treatment in villages and towns, and the sewage from villages and towns is simply collected and treated in a septic tank, and then directly enters the six-stage movable less-aeration ceramic filter bioreactor of the present invention for treatment. The influent CODcr concentration is 300-500mg / L, BOD 5 The concentration is 130-250 mg / L, the concentration of TP is 3-6mg / L, the concentration of TN is 25-45mg / L, and the concentration of ammonia nitrogen is 15-35 mg / L; the relevant effluent indicators can stably meet the "Pollution of urban sewage treatment plants "(GB 18918-2002) Level B requirements. In this example, the total hydraulic retention time of the device of the present invention is 7.8 hours, and the aerobic tank: the anoxic tank: the anaerobic tank quantity ratio is 2:3:1, and the membrane flux is 120L / m 2 .h.

Embodiment 3

[0051] The ceramic filter bioreactor of the present invention is used for the treatment of coking wastewater. After the coking wastewater is pretreated by the grid-grease trap-primary sedimentation-air flotation process, it directly enters the six-stage movable less-aeration ceramic filter biological reaction of the present invention. device for post-processing. Its influent COD cr The concentration is 600-1000mg / L, BOD 5 The concentration is 200-350 mg / L, the ammonia nitrogen concentration is 200-300 mg / L, and the relevant effluent indicators can stably meet the first-level standard for coking wastewater in the "Integrated Wastewater Discharge Standard" (GB8978-96).

[0052] In this example, the total hydraulic retention time of the ceramic bioreactor of the present invention is 24 hours, the quantity ratio of aerobic tank: anoxic tank is 1:1, and anaerobic tank is not provided. The membrane flux is 100L / m 2 .h.

Embodiment 4

[0054] The ceramic filter bioreactor of the present invention is used for the treatment of printing and dyeing wastewater, and the printing and dyeing wastewater is pretreated by a grid-coagulation-sedimentation process, and directly enters the ceramic filter bioreactor of the present invention for post-treatment. Its influent COD cr The concentration is 600-1200mg / L, BOD 5 The concentration is 180-400 mg / L, the chromaticity is 80 times, and the relevant effluent indicators can stably meet the "Water Pollutant Discharge Standards for Textile Dyeing and Finishing Industry" (GB4278-1992).

[0055] In this example, the total hydraulic retention time of the device of the present invention is 30 hours, the ratio of aerobic pool to anoxic pool is 1:1, and no anaerobic pool is set. The membrane flux is 100L / m 2 .h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com