A kind of modification method of molecular sieve

A molecular sieve and modification technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve problems such as difficult fine adjustment of pore size, and achieve the effects of smooth pores, increased exchange degree, and increased loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

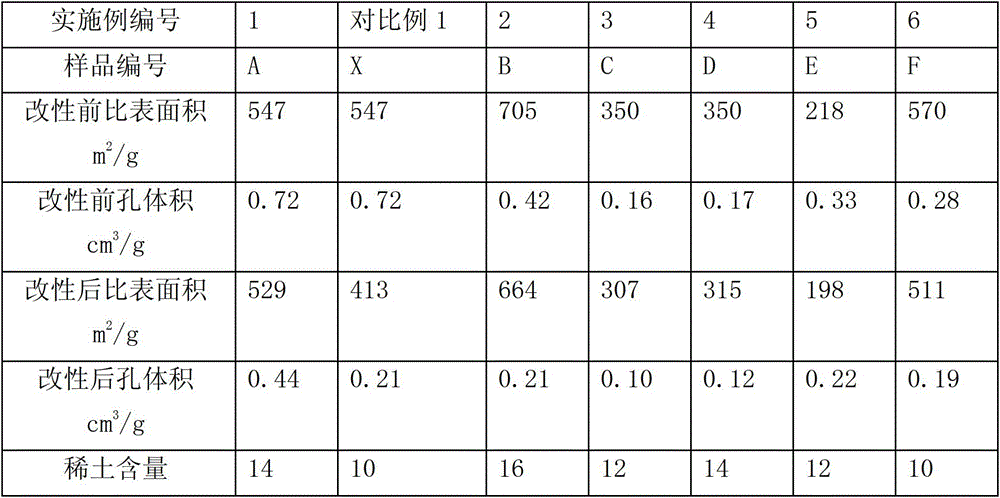

[0029] This example illustrates the modification process of the β molecular sieve provided by the present invention.

[0030] 10g β molecular sieve (provided by Zhoucun Catalyst Factory, SiO 2 / Al 2 o 3 =25,Na 2 O%<0.1%, roasting at 550°C for 2h) Add 10g of diethylamine (Beijing Yili Fine Chemicals Co., Ltd., analytical grade) and 50g of ethanol (Beijing Chemical Plant, analytical grade, the same below), and add it to the pressure melting bomb , heated at 120°C for 24h. Suction filter, wash, and dry the obtained sample at 110°C, add 5 g of the above-mentioned organic base modified sample to 300 g of water, add 40 g of lanthanum nitrate hexahydrate (Sinopharm Chemical Reagent Company, analytical grade, the same below), and exchange at 50°C After 5h, washing and suction filtration, and drying at 110°C, the obtained sample number is A. The results of XRF and BET characterization of sample A are listed in Table 1.

Embodiment 2

[0035] This example illustrates the modification process of the Y-type molecular sieve provided by the present invention.

[0036] 10gY molecular sieve (provided by Changling Catalyst Factory, SiO 2 / Al 2 o 3 =5,Na 2O%<0.1%, roasting at 550°C for 2h) add 10g triethylamine (Beijing Yili Fine Chemicals Co., Ltd., analytical grade) and 50g methanol (Beijing Chemical Plant, analytical grade, the same below), and add them to the pressure melting bomb , heated at 120°C for 144h. Suction filter, wash, and dry the obtained sample at 110°C, add 5 g of the above-mentioned organic base modified sample to 200 g of water, add 30 g of cerium nitrate hexahydrate (Sinopharm Chemical Reagent Company, analytical grade, the same below) and exchange at 60°C After 4 hours, washing and suction filtration, and drying at 110°C, the obtained sample number is B. The results of XRF and BET characterization of sample B are listed in Table 1.

Embodiment 3

[0038] This example illustrates the modification process of the mordenite provided by the present invention.

[0039] 10g mordenite molecular sieve (provided by Zhoucun Catalyst Factory, SiO 2 / Al 2 o 3 =10, Na 2 O%<0.1%, roasting at 550°C for 2h) Add 10g of ethylenediamine (Tianjin Guangfu Technology Development Co., Ltd., analytically pure) and 50g of deionized water, add to the pressure melting bomb, and heat at 150°C for 1h. Suction filter, wash, and dry the obtained sample at 110°C, then add 200 g of water to the above-mentioned organic base modified sample, add 30 g of lanthanum nitrate hexahydrate, exchange at 70°C for 3 hours, wash and suction filter, and dry at 110°C, the obtained sample The number is C. The results of XRF and BET characterization of sample C are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com