Method for producing fluoride and white carbon black by accelerating hydrolysis of fluosilicate with ultrasonic waves

A fluorosilicate and ultrasonic technology, applied in the chemical industry, can solve the problems of high energy consumption, high equipment material requirements, and high raw material cost, and achieve the effects of lowering the reaction synthesis temperature, easy engineering scale-up, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

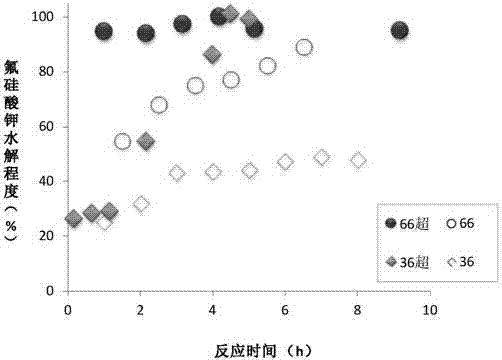

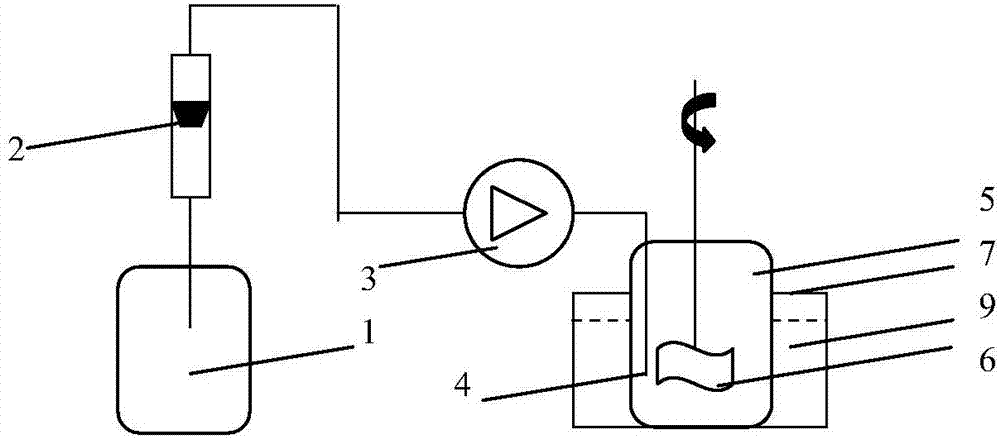

[0048] See figure 1 , with K 2 SiF 6 and KOH to prepare KF and SiO 2 .

[0049] The stirring device 6 is a rotor under the action of a magnetic stirrer. The ultrasonic generator is a probe type ultrasonic generator.

[0050] 1. Add 67g KOH and 400g water to Reaction Tank 1 to form a uniformly mixed KOH solution.

[0051] 2. Add 66 g of potassium fluorosilicate and 700 g of water to the reaction tank 5, turn on the stirring device 6, set the stirring intensity of the stirring device 6 to 400 r / min, so that the stirring effect of the solution in the reaction tank 5 on the stirring device 6 Down, mix well.

[0052] 3. Add the lye in the reaction tank 1 to the reaction tank 5 via the metering pump 3 and the flow meter 2.

[0053] 4. Turn on the ultrasonic generator 7, adjust the constant temperature of the ultrasonic wave to 55°C, and make the ultrasonic wave generated by the ultrasonic probe 8 act on the solution in the reaction tank 5.

[0054] 5. When the fluoride ion c...

Embodiment 2

[0062] See figure 2 . with K 2 SiF 6 and KOH to prepare KF and SiO 2 .

[0063] The stirring device 6 is a paddle mixer, and the ultrasonic generator 7 is an ultrasonic cleaning machine.

[0064] 1. Add 6.7g KOH and 20g water to Reaction Tank 1 to form a uniformly mixed KOH solution.

[0065] 2. Add 6.6g potassium fluorosilicate and 90g water to the reaction tank 5, turn on the stirring device 6, set the stirring intensity of the stirring device 6 to 400r / min, so that the solution in the reaction tank 5 can be stirred by the stirring device 6 Down, mix well.

[0066] 3. Turn on the ultrasonic generator 7, the ultrasonic intensity of the ultrasonic cleaning machine is 100 watts, and the ultrasonic temperature is set to a constant temperature of 36 °C.

[0067] 4. Add the solution in the reaction tank 1 to the reaction tank 5, so that the mixed solution reacts under the action of ultrasonic waves to generate potassium fluoride and SiO 2 .

[0068] 5. Measure the fluori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com