Rice Whitening Machine

A whitening machine and paddy technology, which is applied in grain processing, grain pod removal, grain hulling, etc., can solve the problems of reducing the temperature of the whitening process, and achieve the effects of reducing temperature rise, high kneading precision, and maintaining vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

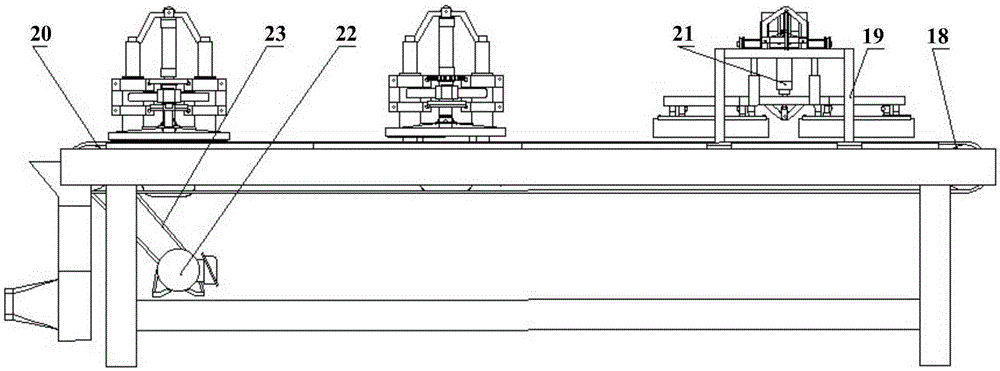

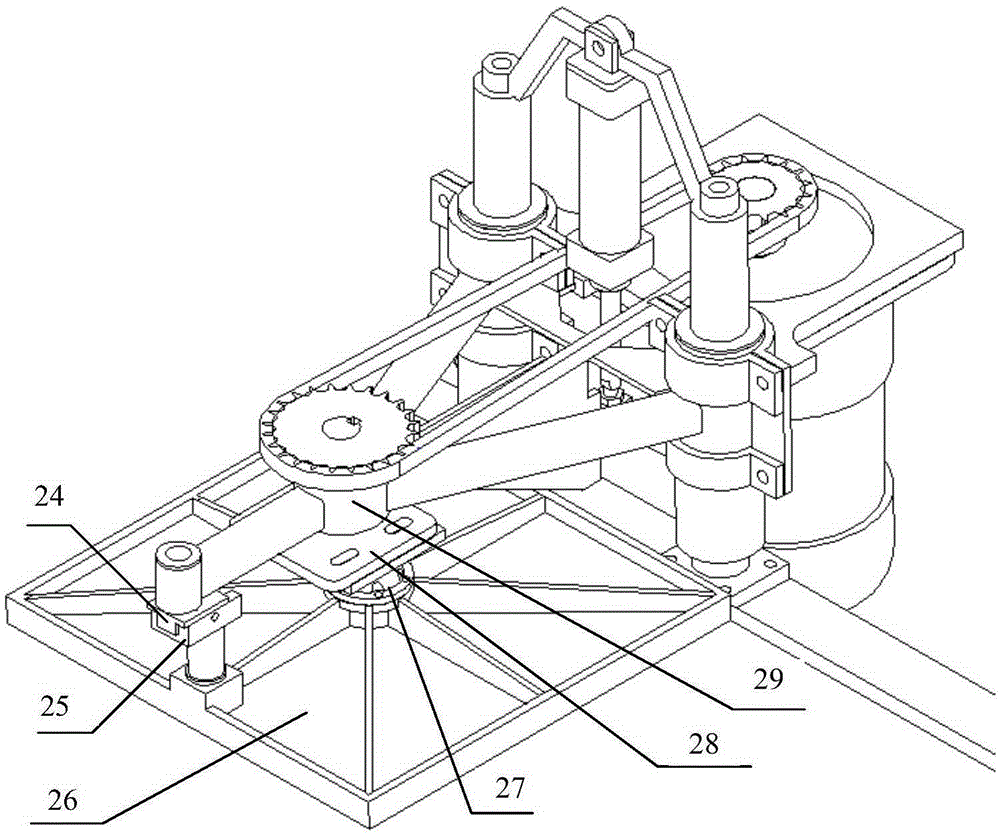

[0015] combined with Figure 1-3 , the present invention mainly comprises frame body 1, rice bucket 2, paddy separator 3, conveyor belt 4, rice kneading mechanism 5, transmission motor 6, transmission chain 7, rice kneading lifting cylinder 8, kneading rice lifting cylinder support 9, sliding Frame 10, transmission motor bracket 11, column 12, air suction mechanism 13, grain box 14, translation cylinder 15, pulley 16, suction cup 17, driven roller 18, bracket 19, driving roller 20, suction cup lifting cylinder 21, conveyor belt motor 22 , Conveyor belt chain 23, slide block 24, slide block guide rail 25, rub rice dish 26, auxiliary shaft 27, connecting plate 28 and main shaft 29.

[0016] After the driving roller 20 and the driven roller 18 penetrate into the two ends of the conveyor belt 4 respectively, they are installed on the left and right ends of the frame body 1 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com