Liquid crystal orientation treatment agent, liquid crystal orientation membrane, and liquid crystal display element

A liquid crystal alignment and treatment agent technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of poor residual charge characteristics, etc., and achieve the effects of excellent coating uniformity, high pre-tilt angle, and less accumulated charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

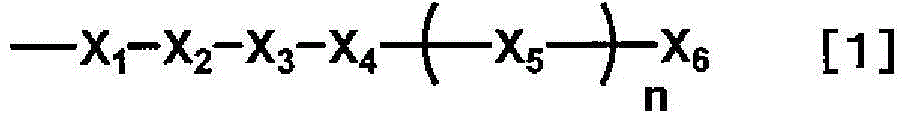

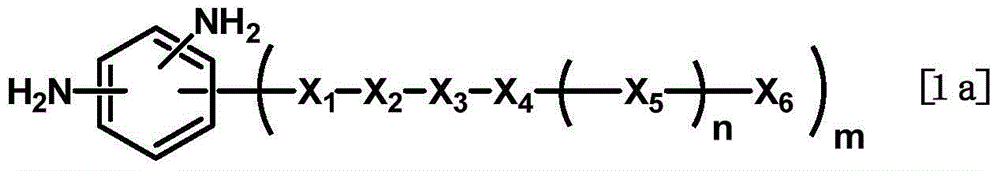

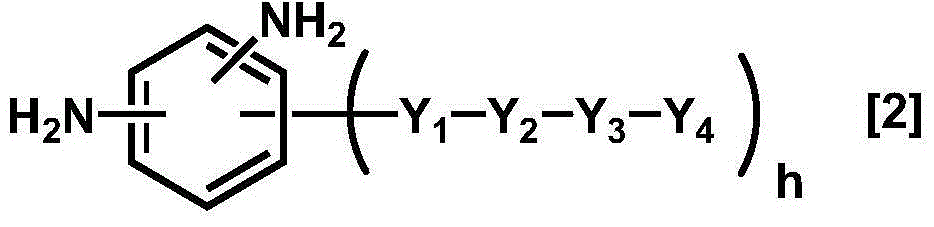

Method used

Image

Examples

Embodiment 1

[0458] Mix A-2 (48.9g, 19.5mmol), B-1 (31.0g, 6.89mmol), B-3 (17.4g, 16.0mmol) in NMP (290g) and make it react at 40°C After 5 hours, A-1 (5.77g, 2.94 mmol) and NMP (120g) were added, it was made to react at 40 degreeC for 15 hours, and the solution (concentration 20.0 mass %) of a polyamic acid was obtained. The polyamic acid had a number average molecular weight of 11,700 and a weight average molecular weight of 40,600.

[0459] After adding NMP to the solution (485 g) of this polyamic acid and diluting to 6 mass %, acetic anhydride (66.2 g) and pyridine (34.2 g) were added as an imidization catalyst, and it was made to react at 100 degreeC for 2.5 hours. This reaction solution was poured into methanol (6010 g), and the generated precipitate was separated by filtration. This deposit was washed with methanol, and dried under reduced pressure at 100°C to obtain a polyimide powder (corresponding to the specific polymer (A)). The imidization rate of this polyimide was 60%, the...

Embodiment 2

[0462] A-2 (236g, 94.0 mmol), B-2 (84.5g, 22.2 mmol), B-4 (53.7g, 22.1 mmol), B-5 (101g, 66.3 mmol) in NMP (1510g ) and allowed to react at 80°C for 5 hours, A-1 (30.4g, 15.5mmol) and NMP (506g) were added and reacted at 40°C for 15 hours to obtain a solution of polyamic acid (concentration 20.0 quality%). The polyamic acid had a number average molecular weight of 12600 and a weight average molecular weight of 61400.

[0463] After adding NMP to the solution (600g) of this polyamic acid and diluting to 6 mass %, acetic anhydride (268g) and pyridine (41.6g) were added as an imidization catalyst, and it was made to react at 100 degreeC for 4 hours. This reaction solution was poured into methanol (8080 g), and the generated precipitate was separated by filtration. This deposit was wash|cleaned with methanol, and it dried under reduced pressure at 100 degreeC, and obtained the powder (corresponding to the specific polymer (B)) of a polyimide. The imidization rate of this poly...

Embodiment 3

[0466] By the polyimide solution (A) obtained by embodiment 1 and the polyimide solution (B) obtained by embodiment 2 according to polyimide solution (A) and polyimide solution (B) with mass % The conditions calculated as 20:80 were mixed at room temperature, and D-1 was further added at 3% by mass relative to the polyimide, stirred, and pressure-filtered with a membrane filter with a pore diameter of 1 μm to obtain Example 3. Liquid crystal aligning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com