Polishing pad

A polishing pad and polyurethane resin technology, applied in the field of polishing pads, can solve problems such as scratches on polishing materials, and achieve the effects of excellent flattening properties, large wear parameters, and excellent dressability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

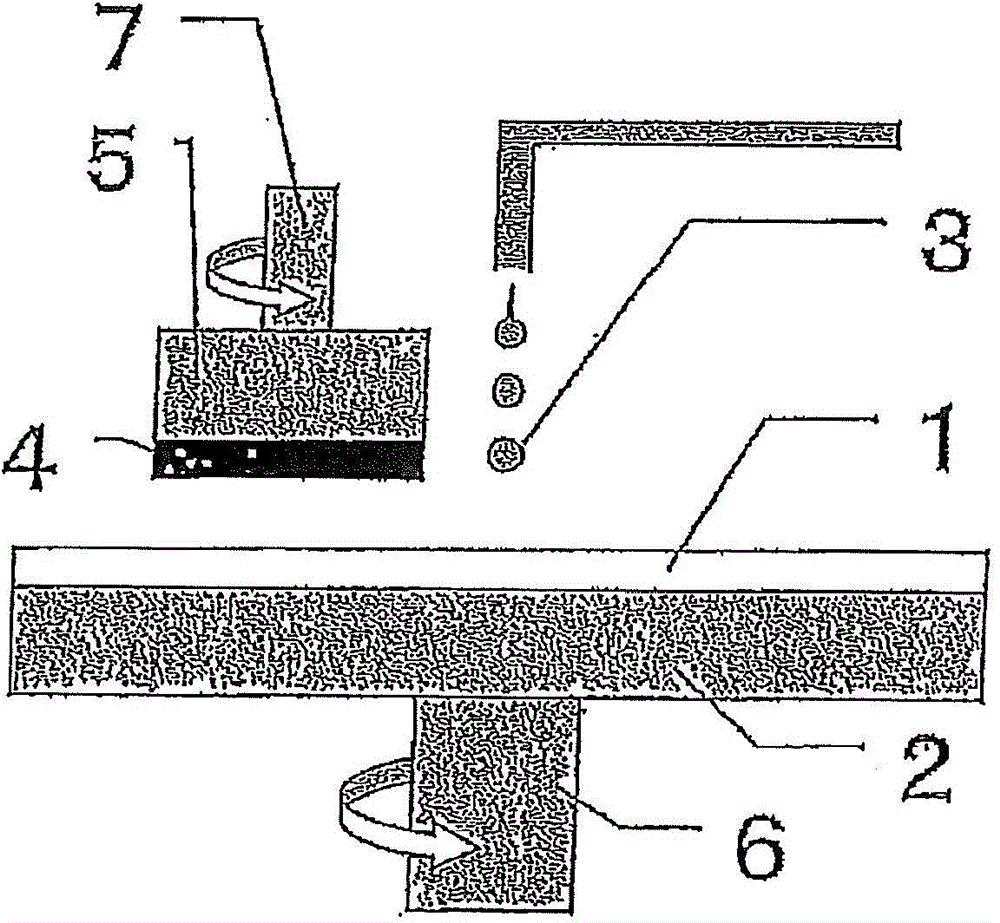

Image

Examples

Embodiment 1

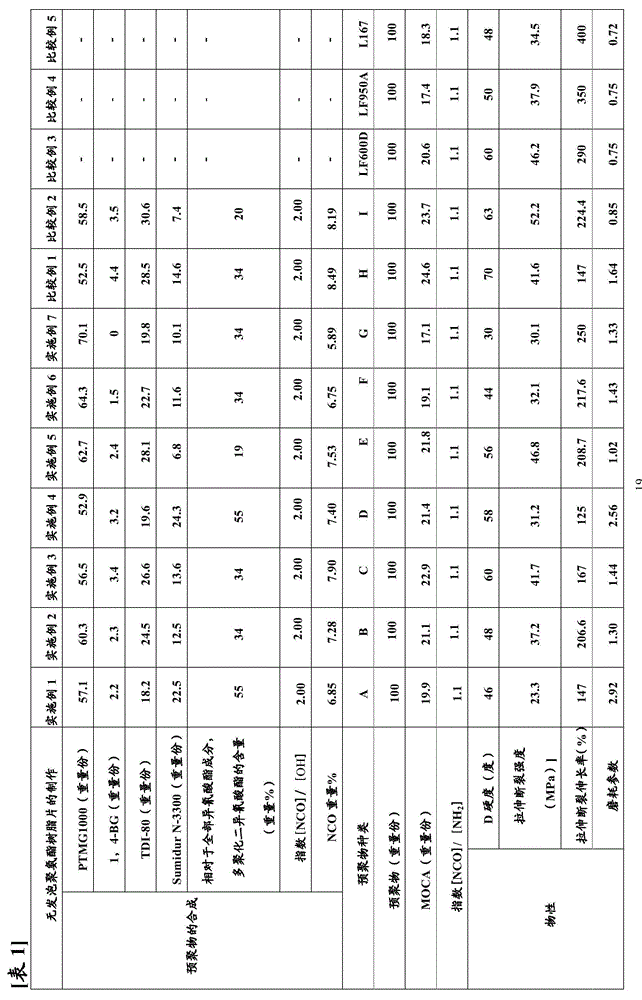

[0137] (Production of non-foamed polyurethane resin sheet)

[0138] 18.2 parts by weight of toluene diisocyanate (manufactured by Mitsui Chemicals, TDI-80, a mixture of 2,4-isomer / 2,6-isomer=80 / 20), 22.5 parts by weight of multimerization 1 , 6-hexamethylene diisocyanate (Sumidur N-3300, isocyanurate type, manufactured by Sumika Bayer Urethane Co., Ltd.), 57.1 parts by weight of polytetramethylene ether glycol (manufactured by Mitsubishi Chemical Corporation, PTMG1000, hydroxyl Value: 112.2KOHmg / g), 2.2 parts by weight of 1,4-butanediol (manufactured by NACALAI Chemical Co., Ltd., 1,4-BG), and reacted at 70° C. for 4 hours to obtain an isocyanate-terminated prepolymer A. Moreover, content of polymerized 1, 6- hexamethylene diisocyanate was 55 weight% with respect to the whole isocyanate component.

[0139] Add 100 parts by weight of the prepolymer A and 19.9 parts by weight of 4,4'-methylene bis(o-chloroaniline) melted at 120°C to a planetary stirring defoaming device for def...

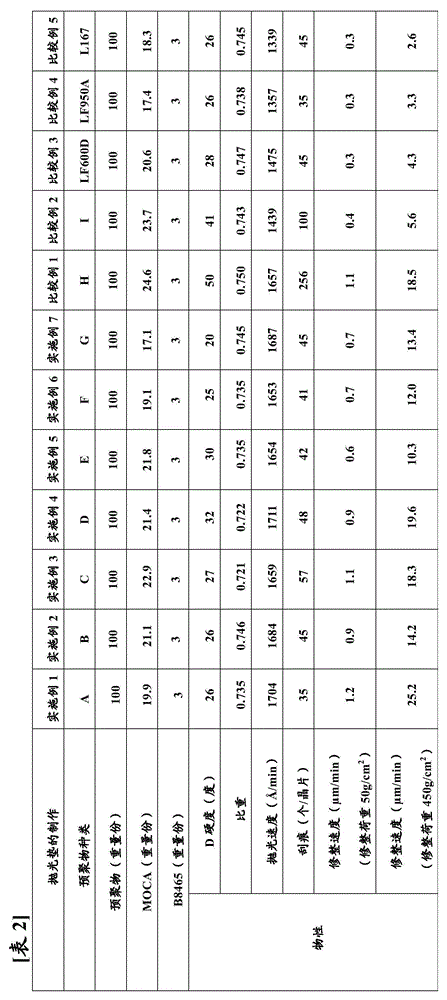

Embodiment 2-7、 comparative example 1-5

[0144] A non-foaming polyurethane resin sheet and a polishing pad were produced in the same manner as in Example 1 except that the compounding quantities described in Table 1 and Table 2 were used. The compounds in Table 1 and Table 2 are described below.

[0145] LF600D: manufactured by Chemtura, a prepolymer synthesized from toluene diisocyanate and polytetramethylene ether glycol, NCO wt% = 7.25

[0146] LF950A: manufactured by Chemtura, a prepolymer synthesized from toluene diisocyanate and polytetramethylene ether glycol, NCO wt% = 6.05

[0147] L167: manufactured by Chemtura, a prepolymer synthesized from toluene diisocyanate and polytetramethylene ether glycol, NCO wt% = 6.30

[0148]

[0149]

Embodiment 8

[0151] (Manufacturing of polishing pads)

[0152] 100 parts by weight of the prepolymer F, 3 parts by weight of a silicon-based surfactant (manufactured by Goldschmidt, B8465) and 0.75 parts by weight of a tertiary amine catalyst (manufactured by Kao Company, KAO: No25 (N,N-dimethylamino Hexanol)) was added into the polymerization container, mixed, adjusted to 80° C., and degassed under reduced pressure. Then, vigorously stirred at 900 rpm using a stirring blade for about 4 minutes so as to introduce air bubbles into the reaction system. 19.1 parts by weight of 4,4'-methylenebis(o-chloroaniline) previously melted at 120° C. was added thereto. After stirring this liquid mixture for about 1 minute, it poured into the flat-bottomed open mold (injection molding container). When the fluidity of the liquid mixture disappeared, it was placed in an oven, and post-cured at 100° C. for 16 hours to obtain a polyurethane resin foam block.

[0153] The polyurethane resin foam block heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com