A method of manufacturing a microlens array

A technology of micro-lens array and micro-convex lens array, applied in the directions of lenses, manufacturing tools, instruments, etc., can solve the problems of high production cost, large laser processing size, complex process, etc., and achieves low cost, large processing size and high speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

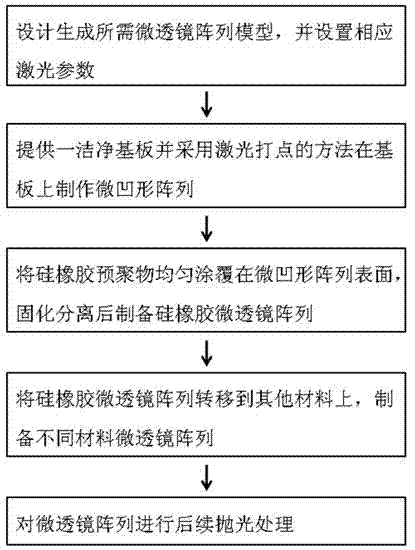

[0030] A method for manufacturing a microlens array, comprising the following steps,

[0031] S1: Design and generate the required microlens array model, and set the corresponding laser power, laser beam spot size and laser dwell time according to the parameters of the required microlens array;

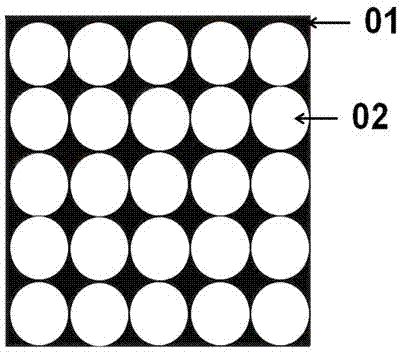

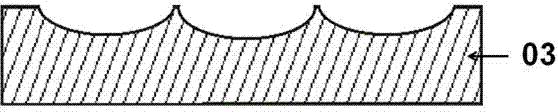

[0032] S2: Provide a clean substrate and make a dimple array on the substrate by laser dotting;

[0033] S3: Coating the silicone rubber prepolymer evenly on the surface of the micro-concave array, preparing a silicone rubber micro-convex lens array after curing and separating, and performing polishing treatment.

[0034] In the step S3, the silicone rubber micro-convex lens array is transferred to a substrate to prepare the micro-convex lens array of the substrate.

[0035] The described silicone rubber micro-convex lens array is transferred t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com