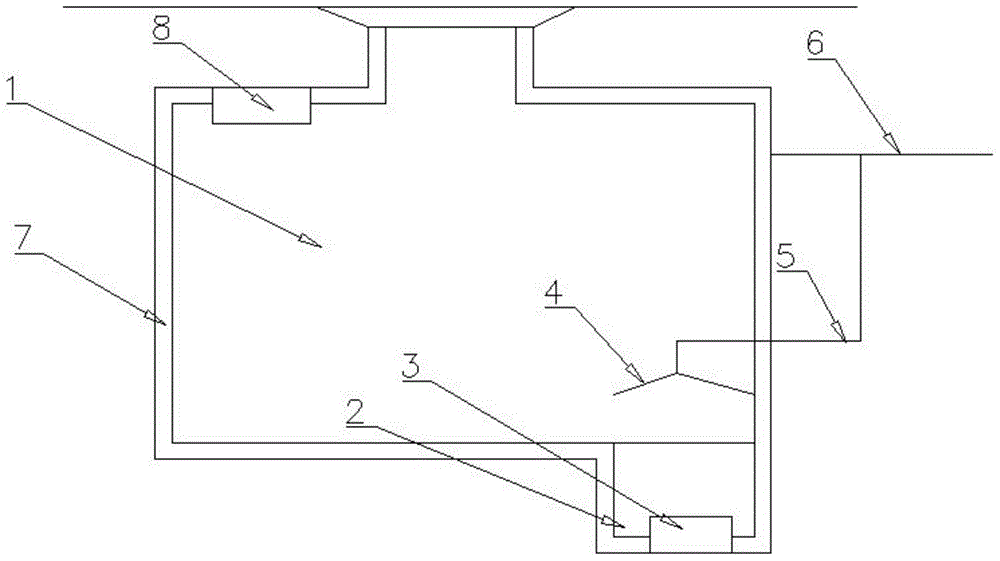

Waterproof cable well

A waterproof cable and well body technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of reducing the continuous use effect of cables and increasing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The components and parts by weight of the water-repellent coating in this embodiment are: 60 parts of polyether (polyethylene glycol ether), 6 parts of epoxy resin, 10 parts of polytetrafluoroethylene, 10 parts of polyether ether ketone, plasticized 0.5 parts of agent (dioctyl phthalate), 10 parts of polyurethane (polyurethane), 1 part of simethicone, 5 parts of nano silicon dioxide, and 30 parts of ethanol (40%).

[0030] The preparation method of the above-mentioned water-repellent coating in this embodiment, the specific steps include:

[0031] (4) First mix the polyether (polyethylene glycol ether), epoxy resin, polytetrafluoroethylene, polyether ether ketone, and plasticizer in the proportion of the formula, and then stir and mix at 80-160 ° C for 2-2.5 h;

[0032] (5) Mix polyurethane, simethicone, nano-silica, and ethanol according to the formula ratio, then heat and reflux for 6-7 hours;

[0033] (6) Mix the materials obtained in step (1) and step (2), and the...

Embodiment 2

[0035] The components and parts by weight of the water-repellent coating in this embodiment are: 85 parts of polyether (polyethylene glycol ether), 5 parts of epoxy resin, 12 parts of polytetrafluoroethylene, 12 parts of polyetheretherketone, plasticized Agent (diisooctyl phthalate) 1.5 parts, polyurethane (polyurethane) 12 parts, simethicone 2 parts, nano silicon dioxide 6 parts, ethanol (20-60%) 40 parts.

[0036] The preparation method is the same as in Example 1.

[0037] During construction, use conventional mechanical spraying, brushing, etc. to coat the inner surface of the cable well.

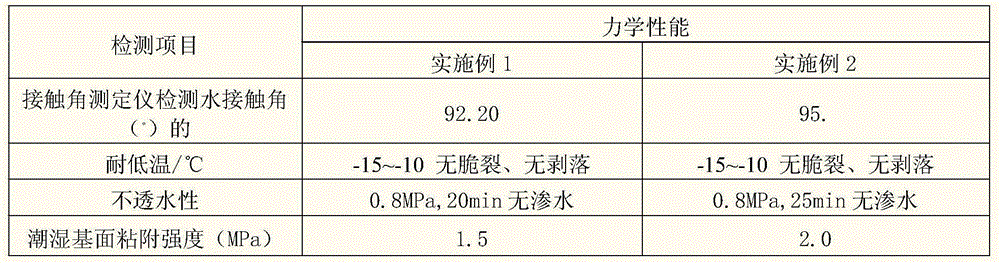

[0038] Above-mentioned coating performance of the present invention is as shown in table 1 below:

[0039] Table 1 Coating performance of the embodiment of the present invention

[0040]

[0041]It can be seen from the above table that the present invention has good water repellency, is not easy to permeate water, and has strong adhesion to the inner surface of the well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com