A kind of beaded porous PLA nanofiber and its preparation method and application

A nanofiber and bead-like technology, which is applied in the field of beaded porous PLA nanofiber and its preparation, to achieve the effects of reducing resistance, high specific surface area, and facilitating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

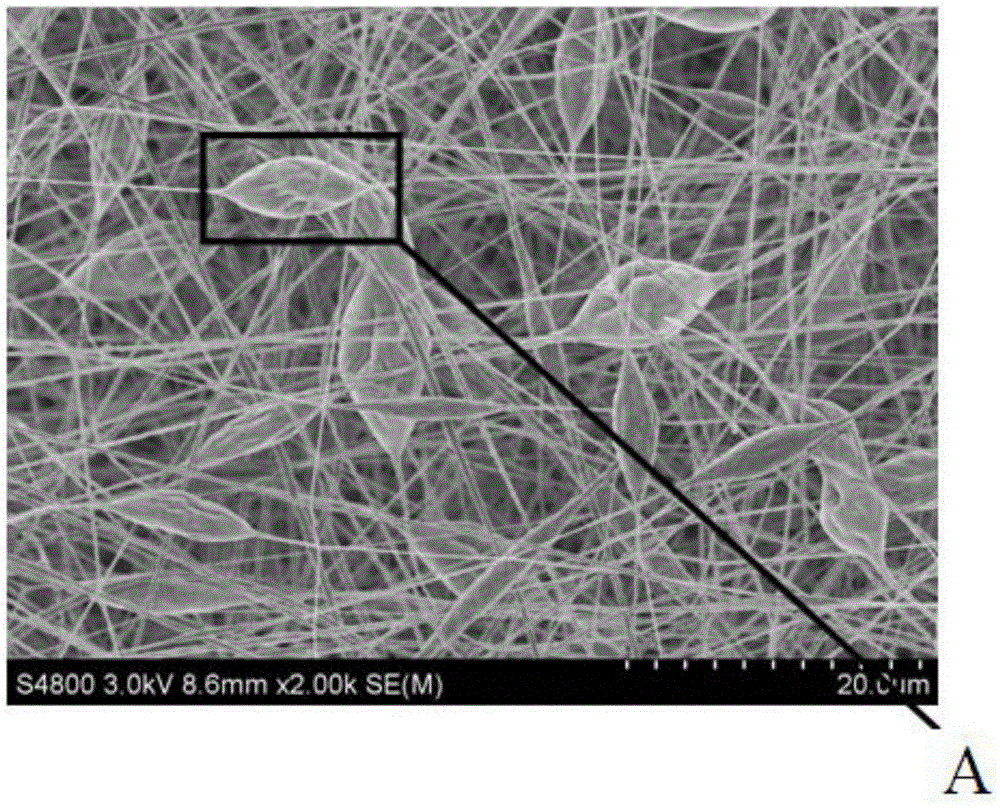

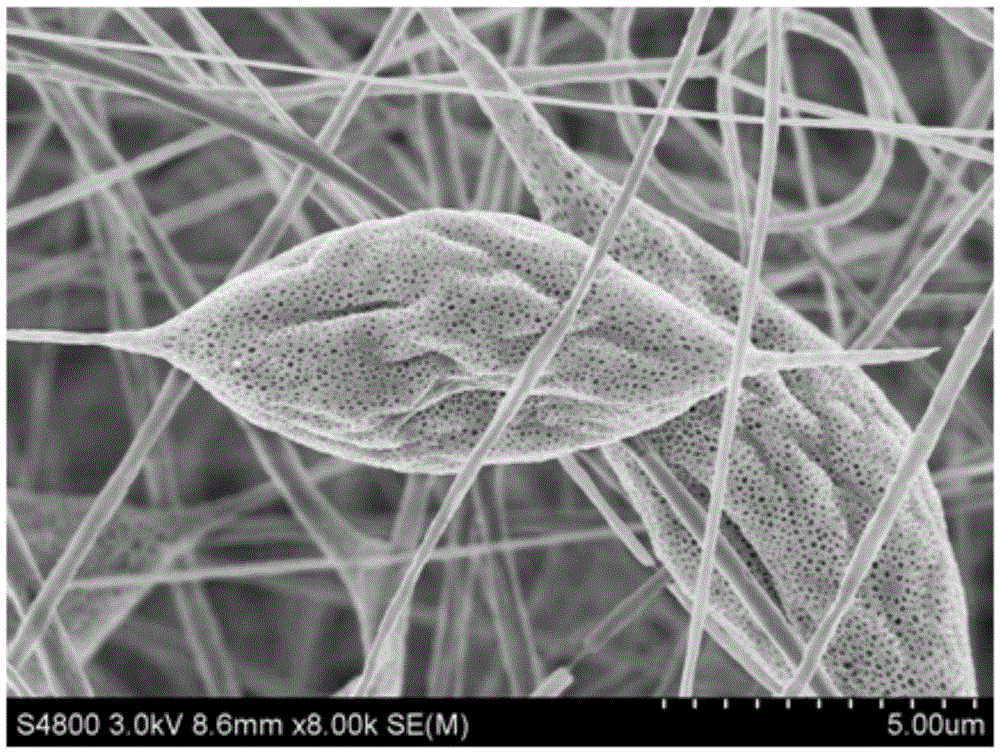

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of preparation method of beaded porous PLA nanofiber, its steps are as follows:

[0038] 1) Preparation of spinning solution

[0039] Mix dichloromethane and N,N-dimethylacetamide in a mass ratio of 10:1 as a mixed solvent, weigh 0.5 g of PLA polymer particles and dissolve them in 9.5 g of the above mixed solvent, and then Under stirring by a magnetic stirrer, a uniformly mixed transparent solution (spinning solution) with a mass fraction of 5% was prepared.

[0040] 2) Preparation of beaded porous PLA nanofiber air filtration membrane

[0041] The spinning liquid that step 1) is made carries out electrospinning, and the process condition of electrospinning is as follows:

[0042] Electrospinning was carried out under the conditions of spinning voltage of 15kV, spinning liquid flow rate of 1mL / h, collection roller speed of 5.5m / min, and spinning distance of 12cm.

[0043] The conventional horizontal electrospinning method is adopted, and the conven...

Embodiment 2

[0047] Embodiment 2: a kind of preparation method of beaded porous PLA nanofiber, its steps are as follows:

[0048] 1) Preparation of spinning solution

[0049] Dichloromethane and N,N-dimethylacetamide are mixed in a mass ratio of 10:1 as a mixed solvent, and 0.45g of PLA polymer particles are weighed, dissolved in 9.55g of the mixed solvent, and then A homogeneously mixed transparent solution (spinning solution) with a mass fraction of 4.5% was prepared by stirring with a magnetic stirrer at room temperature.

[0050] 2) Preparation of beaded porous PLA nanofiber air filtration membrane

[0051] The spinning liquid that step 1) is made carries out electrospinning, and the process condition of electrospinning is as follows:

[0052] Electrospinning was carried out under the conditions of spinning voltage of 15kV, spinning liquid flow rate of 1mL / h, collection roller speed of 5.5m / min, and spinning distance of 12cm.

[0053] The conventional horizontal electrospinning meth...

Embodiment 3

[0056] Embodiment 3: a kind of preparation method of beaded porous PLA nanofiber, its steps are as follows:

[0057] 1) Preparation of spinning solution

[0058] Mix dichloromethane and N,N-dimethylacetamide in a mass ratio of 10:1 as a mixed solvent, weigh 0.55g of PLA polymer particles and dissolve them in 9.45g of mixed solvent, and then pass through Stirring with a magnetic stirrer prepared a homogeneously mixed transparent solution (spinning solution) with a mass fraction of 5.5%.

[0059] 2) Preparation of beaded porous PLA nanofiber air filtration membrane

[0060] The spinning liquid that step 1) is made carries out electrospinning, and the process condition of electrospinning is as follows:

[0061] Electrospinning was carried out under the conditions of spinning voltage of 15kV, spinning solution flow rate of 1mL / h, collection roller speed of 5.5m / min, and spinning distance of 12cm.

[0062] The conventional horizontal electrospinning method is adopted, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com