Method for processing spring steel arch belt

A processing method and technology of spring steel, applied in the field of spring steel bow belt, can solve the problems of low strength of spring steel bow belt, reduce the rotation speed of double twist machine, increase production cost, etc., achieve excellent organizational structure, reduce the risk of cracking, Guaranteed rotation speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] A processing method for a spring steel bow belt, characterized in that it comprises the following steps:

[0028] Step 1: Put the molten steel into the existing spring steel bow belt mold (leave a margin of 0.3-0.5mm in the thickness direction of the mold when blanking, on the one hand, this margin is used to provide sufficient grinding allowance, on the other hand The decarburization layer that may be generated on the surface can be removed), and the spring steel bow strip blank is formed after cooling;

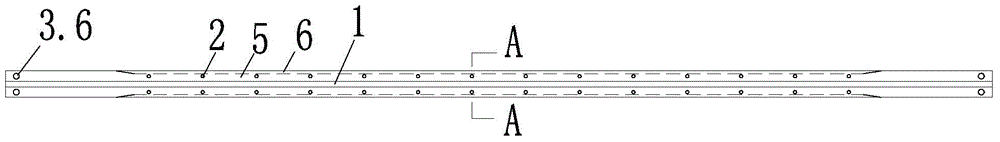

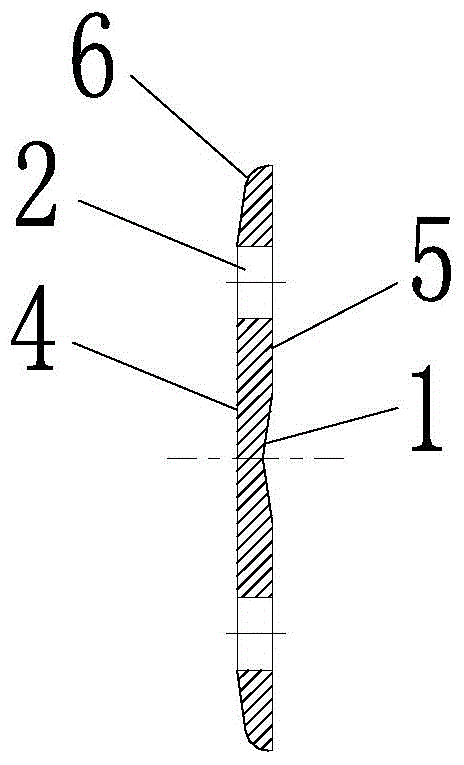

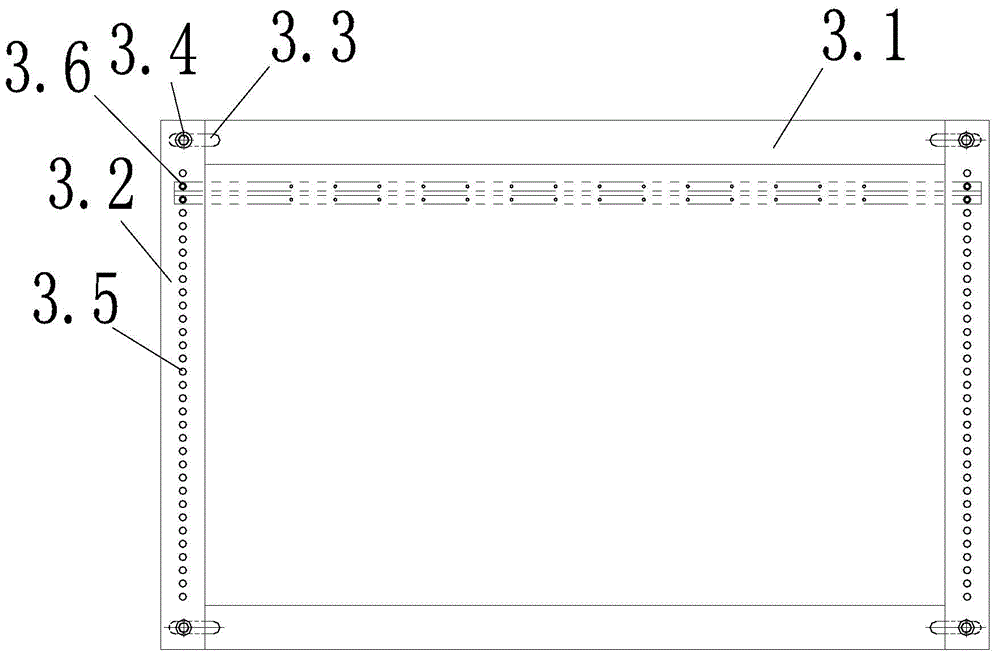

[0029] Step 2: Use a punching machine (350T hydraulic punching machine) to punch out the center groove 1 of the bow strap on the blank of the spring steel bow strap (the center groove 1 of the punched bow strap is used to strengthen the strap), and then use a drilling machine to punch the blank of the spring steel bow strap Drill the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com