An air film insulation structure and construction method adaptable to air pressure changes

A construction method and air pressure change technology, applied to special structures, dome structures, heat preservation, etc., to avoid repeated expansion and contraction, ensure heat insulation effect, and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

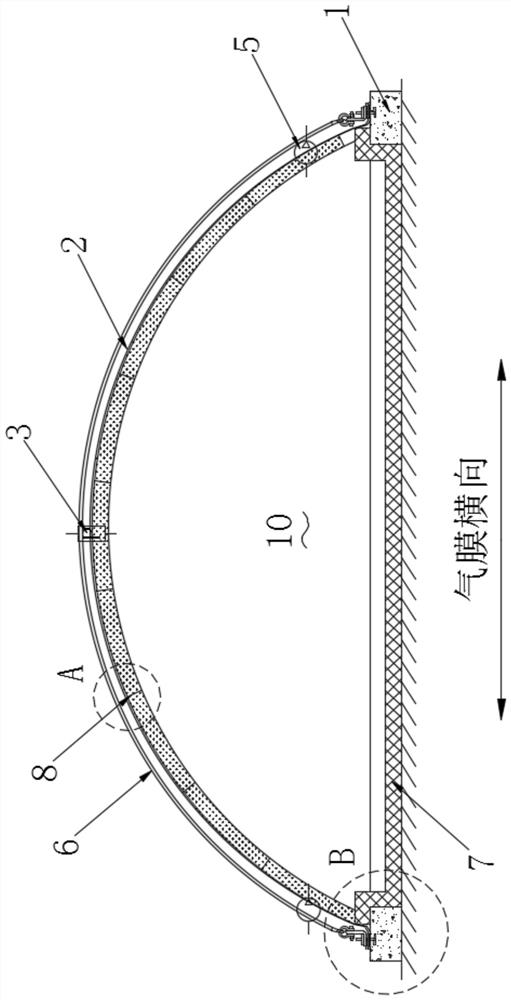

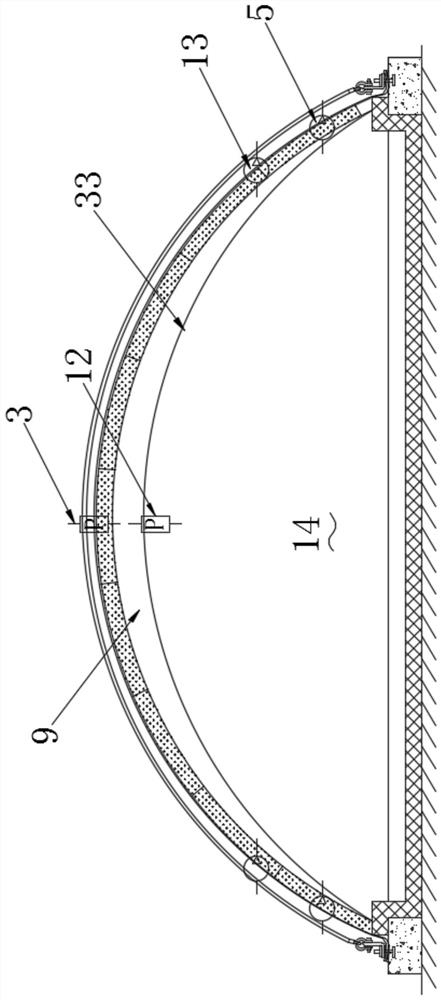

[0046] The air-film thermal insulation structure adapting to changes in air pressure provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 As shown, the air film insulation structure provided in this embodiment includes an air film 2, a first differential pressure sensor 3, a first pressurizing device 5 and a control system.

[0047] Specifically, a base body 1 is pre-formed on the ground. The base body 1 may be formed by pouring concrete or a counterweight object. The edge of the air film 2 is sealed on the base body 1 to define a building space 10 below the air film 2 .

[0048] The first differential pressure sensor 3 is installed on the gas film 2, and one gas pipe is connected to the inside of the gas film 2, and one gas pipe is connected to the outside of the gas film 2, and is used to measure the pressure difference between the gas pressure inside the gas film 2 and the atmospheric pre...

Embodiment 2

[0089] This embodiment provides a construction method for constructing the air-film thermal insulation structure described in the embodiment, which specifically includes the following steps:

[0090] First, seal and fix the edge of the air film 2 to the base body 1 and define the building space 10;

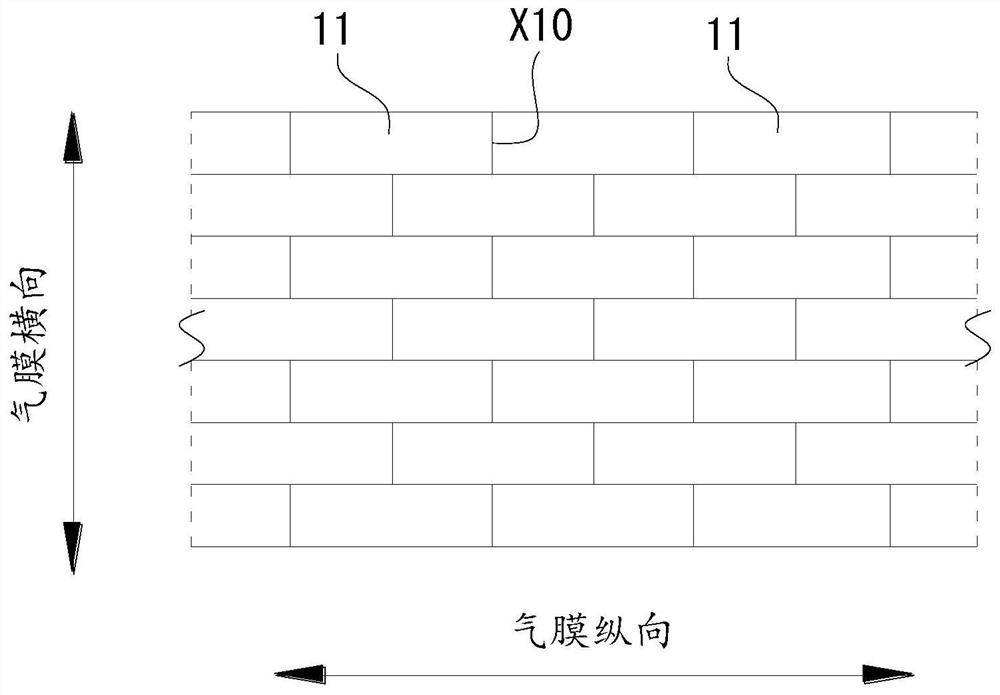

[0091] Then, the air is inflated into the building space 10 to expand the air film 2 , and a thermal insulation sticker is attached to the inner wall of the air film 2 .

[0092] As a further improvement of the present embodiment, the building space 10 is inflated with air before attaching the thermal insulation layer to make the pressure difference between the inside of the building space 10 and the outside of the building space 10 greater than the preset pressure difference; A plurality of flexible heat insulating sheets 11 are attached to form a heat insulating layer, and finally the pressure in the building space 10 is reduced, so that the pressure difference between the build...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com