Leak-proof patch of tubeless tire and production process thereof

A production process and leak-proof technology, applied in the direction of film/sheet adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of occupying a large production site and space, increasing production costs, and inability to Sticking and other problems, to achieve the effect of easy storage and transportation, lower production costs, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

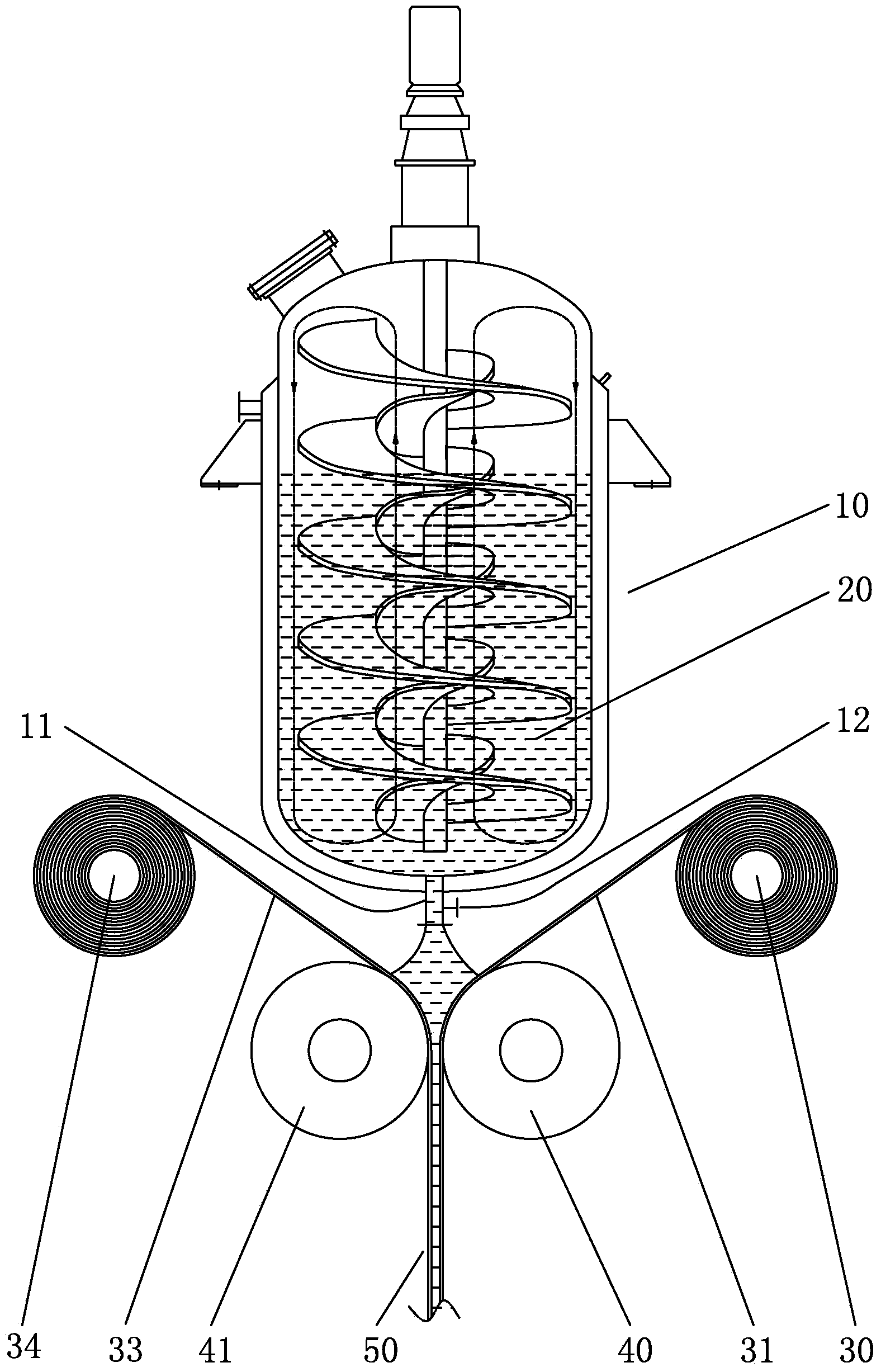

[0034] The production technology of tubeless tire leak-proof patch is prepared by the following steps (see figure 2 , image 3 ):

[0035] (1) take respectively the tubeless tire leak-proof raw material of given weight parts;

[0036] (2) After heating the reactor to 130-250° C., put the raw materials weighed in step (1) into the reactor in batches or at one time, and stir until they are in a uniform liquid state to form liquid raw materials;

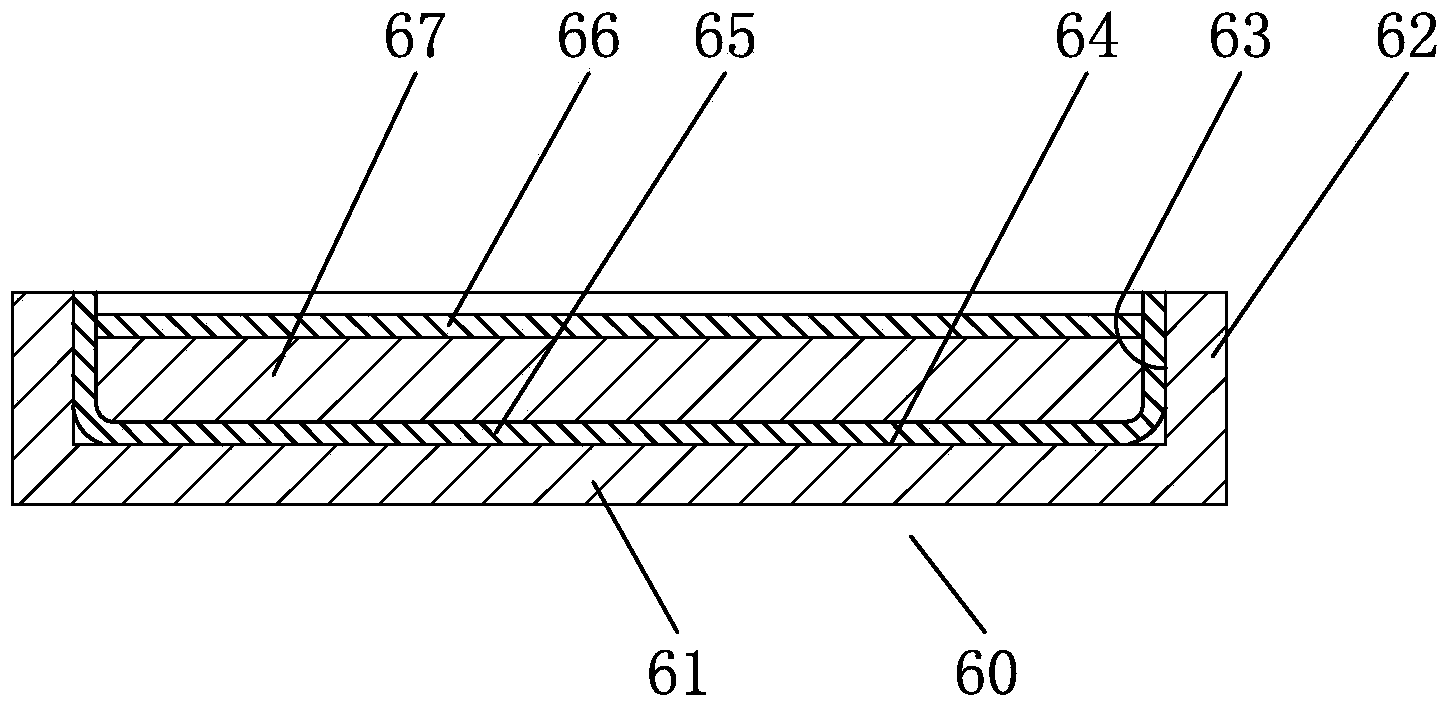

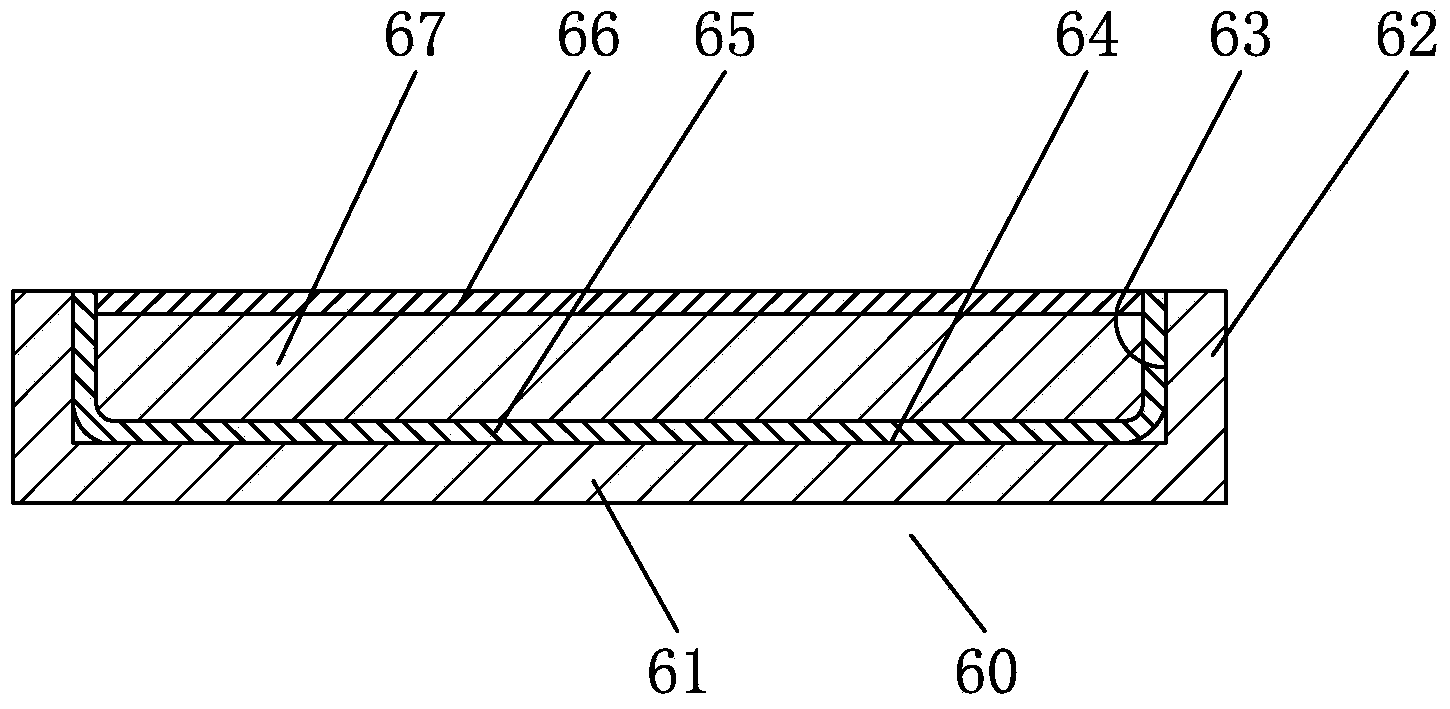

[0037] (3) The bottom 64 of the box body 60 with the upper opening of the bottom 61 and the fence 62 is arranged on all sides to spread one deck of non-stick paper 65 and the non-stick paper 65 of the bottom 64 is bent upwards to the fence inner wall 63 (its height greater than the thickness of the tubeless tire leak-proof patch), the tubeless tire leak-proof patch liquid raw material 67 prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com