Optothermal response system, resin material and optothermal response smart glass

A photothermal response and system technology, applied in the direction of color-changing fluorescent materials, coatings, chemical instruments and methods, etc., can solve the problems of poor permeability, affecting the sight line, etc., achieve good thermal insulation coefficient, reduce use, and reduce heating energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

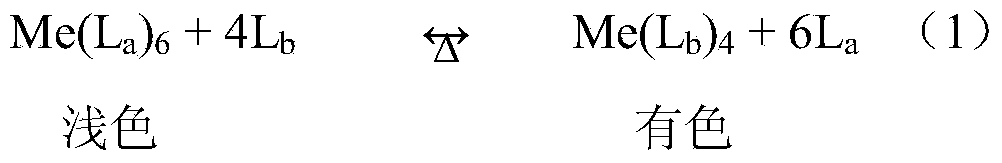

[0071] Dissolve 1 part of cobalt chloride hexahydrate, 0.2 part of propylene glycol, 10 parts of triphenylphosphine, 10 parts of tetrabutylammonium bromide, and 1 part of calcium iodide in 50 ml of anhydrous tetrahydrofuran solution. Add 60 parts of polystyrene, 40 parts of dioxane, 1.5 parts of 2,6-di-tert-butyl-p-phenol and 1 part of tin stearate to the solution. Spin-coat the polymer solution on a glass plate to prepare a 0.2 mm thick film. After the dissolution is completely volatilized, another layer of glass is attached to the surface of the film, and kept at 100 degrees and 1 MPa pressure for 20 minutes to prepare a sandwich-structured laminated glass.

[0072] The glass is colorless and transparent under the condition of no sunlight at 20 degrees, and the shading coefficient Se=0.76. Under the condition of 60 degrees without light, Se=0.65. It turns yellow-green under the condition of strong sunlight at 60 degrees, and the shading coefficient Se=0.3.

Embodiment 2

[0074] 0.1 parts of cobalt chloride hexahydrate, 10 parts of 1,3-butanediol, 0.4 parts of triphenylphosphine, 10 parts of tetrabutylammonium bromide, 10 parts of tetrabutylphosphorus bromide, 0.2 parts of silver chloride, Dissolve in 50 mL of anhydrous butyrolactone solution. Add 90 parts of polyvinyl alcohol, 50 parts of dioxane, 0.5 parts of 2,6-di-tert-butyl-a-dimethylamino-p-cresol and 10 parts of tin stearate in the solution to prepare a 20 cm wide 0.4 mm thick film. The prepared film is placed between two pieces of glass, and hot-pressed at 120 degrees and 2 MPa to form a sandwich-structured laminated glass

[0075] The glass is colorless and transparent under the condition of no sunlight at 20 degrees, and the shading coefficient Se=0.72. When there is no light at 60 degrees, Se=0.67. It turns dark green under the condition of strong sunlight at 60 degrees, and the shading coefficient Se=0.28.

Embodiment 3

[0077] Dissolve 2 parts of cobalt chloride hexahydrate, 10 parts of polyvinyl alcohol, 15 parts of triphenylphosphine, 5 parts of ethyltriphenylphosphorus iodide, and 5 parts of calcium iodide in 50 ml of dimethyl adipate solution middle. Add 61 parts of polystyrene in the solution, 60 parts of dioxane, 1 part of 4,4-bis(2,6-di-tert-butylphenol) and 5 parts of dibutyltin maleate, the polymer The solution was spin-coated on a glass plate to prepare a 0.5 mm thick film. Films with a width of 20 cm and a thickness of 0.5 mm were prepared. The prepared film is placed between two sheets of glass, and hot-pressed at 120 degrees and 2 MPa to prepare a sandwich-structured laminated glass.

[0078] The glass is colorless and transparent under the condition of no sunlight at 20 degrees, and the shading coefficient Se=0.74. When there is no light at 60 degrees, Se=0.68. It turns light green under the condition of strong sunlight at 60 degrees, and the shading coefficient Se=0.26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com