Method and system for drying and incinerating urban household garbage through dry-process rotary kiln

A technology of urban domestic garbage and garbage, which is applied in the direction of cement production and solid waste removal, can solve the problems of small investment and good economy, and achieve the effects of small investment, simple and reliable process, which is beneficial to increase production and save coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

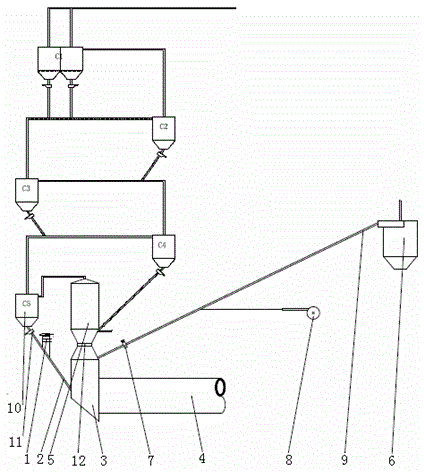

[0024] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025]The dry method rotary kiln drying of the present embodiment, the method for incinerating municipal solid waste, with the C5 feeding pipe of dry method rotary kiln preheater system as the preheating drier of rubbish, with the CaO that flows in the C5 feeding pipe as The main strong alkaline high-temperature powder is used as the preheating drying medium, and the pretreated wet garbage is fed into the C5 feeding pipe through the garbage feeding lock air device, and the high-temperature powder mainly containing CaO in the C5 feeding pipe is used for rapid drying And alkalineize the garbage, so that the moisture in the garbage is vaporized into high-temperature steam, and the dry and flammable garbage enters the smoke chamber at the tail end of the kiln with the powder, and is quickly gasified and bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com