Method for controlling intake air content local nitrogen enriched combustion and NOx emission

An emission control, nitrogen-enriched technology, applied in combustion methods, combustion equipment, fuel air inlets, etc., can solve problems such as variable density distribution of intake components or stratified local zoning control that is not mentioned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

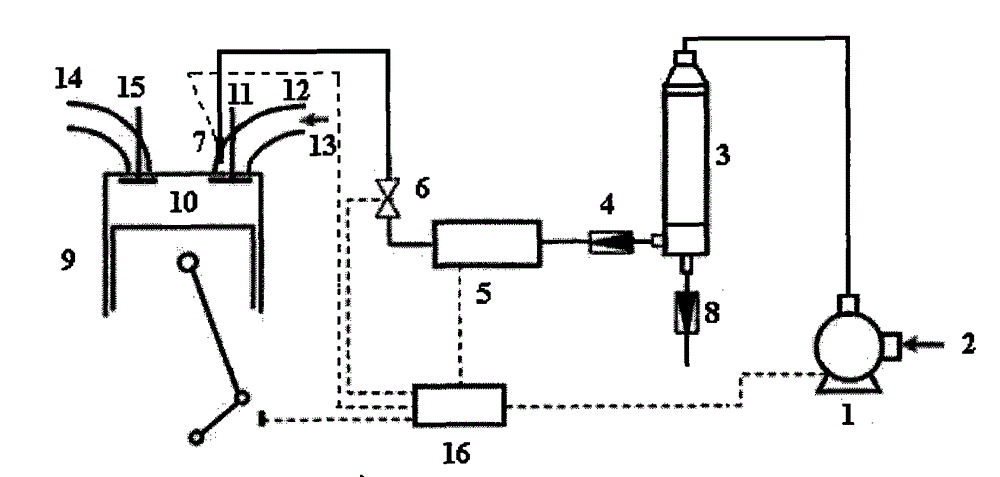

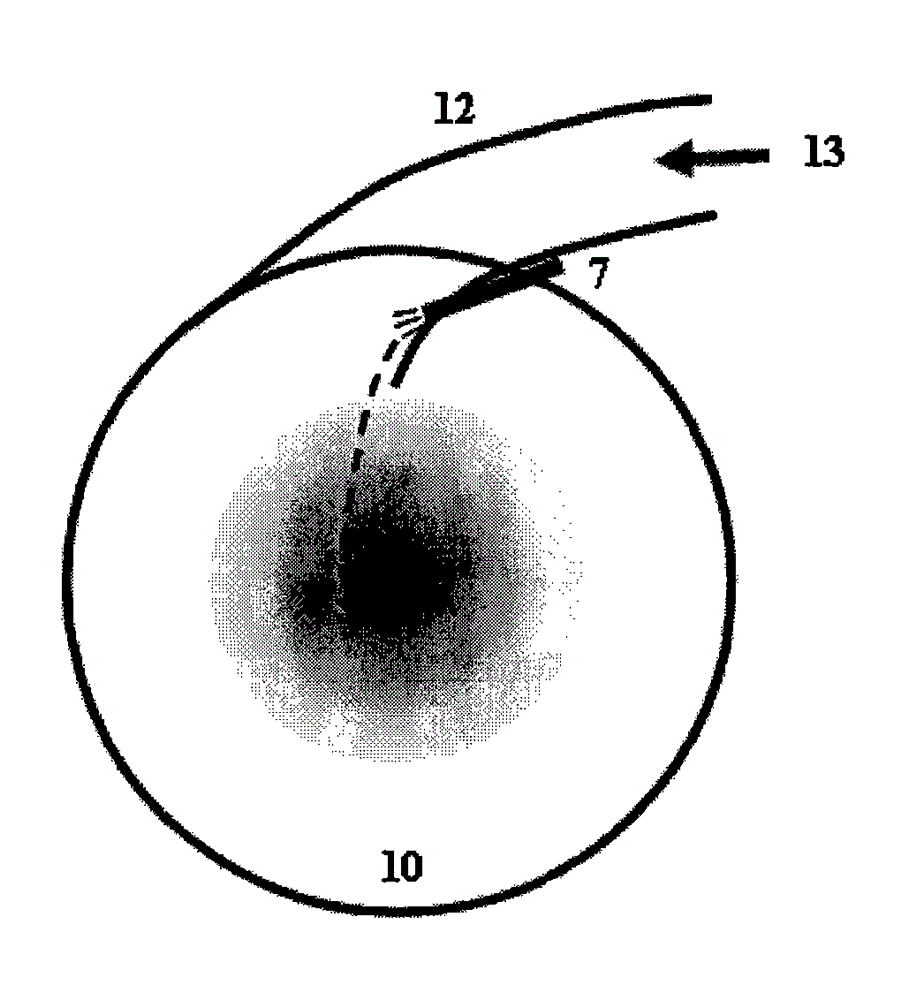

[0017]During the working process of the internal combustion engine, according to the working conditions and operating conditions, through the coordinated control of the auxiliary nitrogen-rich flow injection pressure, timing, injection pulse width, and injection frequency, the variable density distribution and layered internal composition of the intake air components can be realized. Circulation nitrogen-enriched control, that is, the filtered air 2 flowing through the air compressor or supercharger 1 enters the gas separator 3, and the separated nitrogen-enriched gas flows through the check valve 4 and enters the nitrogen-enriched gas storage 5 for storage, wherein, 1. Air compressor or supercharger, 3. Gas separator, check valve 8. Random or non-random equipment can be used. According to the control requirements of the working process, the electric control valve 6 makes the auxiliary nitrogen-enriched air flow pass through the nitrogen-enriched air flow nozzle 7 and inject it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com