Wollastonite-apatite frit compounded medical glass ceramic and preparation method thereof

A technology of glass-ceramic and glass-ceramic frit, which is applied in the field of biological glass ceramics, can solve the problems such as difficult control and change of properties, and achieve the effects of easy industrial promotion and use, guaranteed uniformity, and low preparation process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Wollastonite glass-ceramic frit is made by melting the following raw materials in parts by weight: SiO 2 67.5 parts, CaO20 parts, Na 2 O12.5 copies;

[0034] The apatite glass-ceramic frit is smelted from the following raw materials in parts by weight: SiO 2 46 copies, Al 2 o 3 3.3 parts, CaO10 parts, BaO2 parts, MgO3.6 parts, B 2 o 3 2 parts, Na 2 O+K 2 O13 parts, CaF 2 0.6 parts, P 2 o5 4.5 parts, ZnO3 parts, Sb 2 o 3 1 serving.

[0035] The specific preparation method is as follows:

[0036] (1) Preparation of wollastonite glass-ceramic frit: ①Weigh the wollastonite frit raw material according to the above parts by weight, mix and pour it into a mixer, and stir for 1 hour; Hours, water quenching, drying, crushing and forming frit powder;

[0037] (2) Preparation of apatite glass-ceramic frit: ①Weigh the apatite frit raw material according to the above parts by weight, mix and pour it into a mixer, and stir for 1 hour; ②Pour it into a kiln at 1550°C, and...

Embodiment 2

[0051] The second embodiment is based on the first embodiment, only the ratio of silicon dioxide and calcium oxide in the wollastonite frit is changed, and other proportions remain unchanged. During preparation, the melting temperature of wollastonite frit was 1550° C., and the melting time was 2 hours; the heating rate, sintering temperature and time of sintering after mixing were the same as those in Example 1.

[0052] Wollastonite glass-ceramic frit is made by melting the following raw materials in parts by weight: SiO 2 62.5 parts, CaO25 parts, Na 2 O12.5 parts; Apatite glass-ceramic frit is formed by melting the raw materials of following parts by weight: SiO 2 46 copies, Al 2 o 3 3.3 parts, CaO10 parts, BaO2 parts, MgO3.6 parts, B 2 o 3 2 parts, Na 2 O+K 2 O13 parts, CaF 2 0.6 parts, P 2 o 5 4.5 parts, ZnO3 parts, Sb 2 o 3 1 serving.

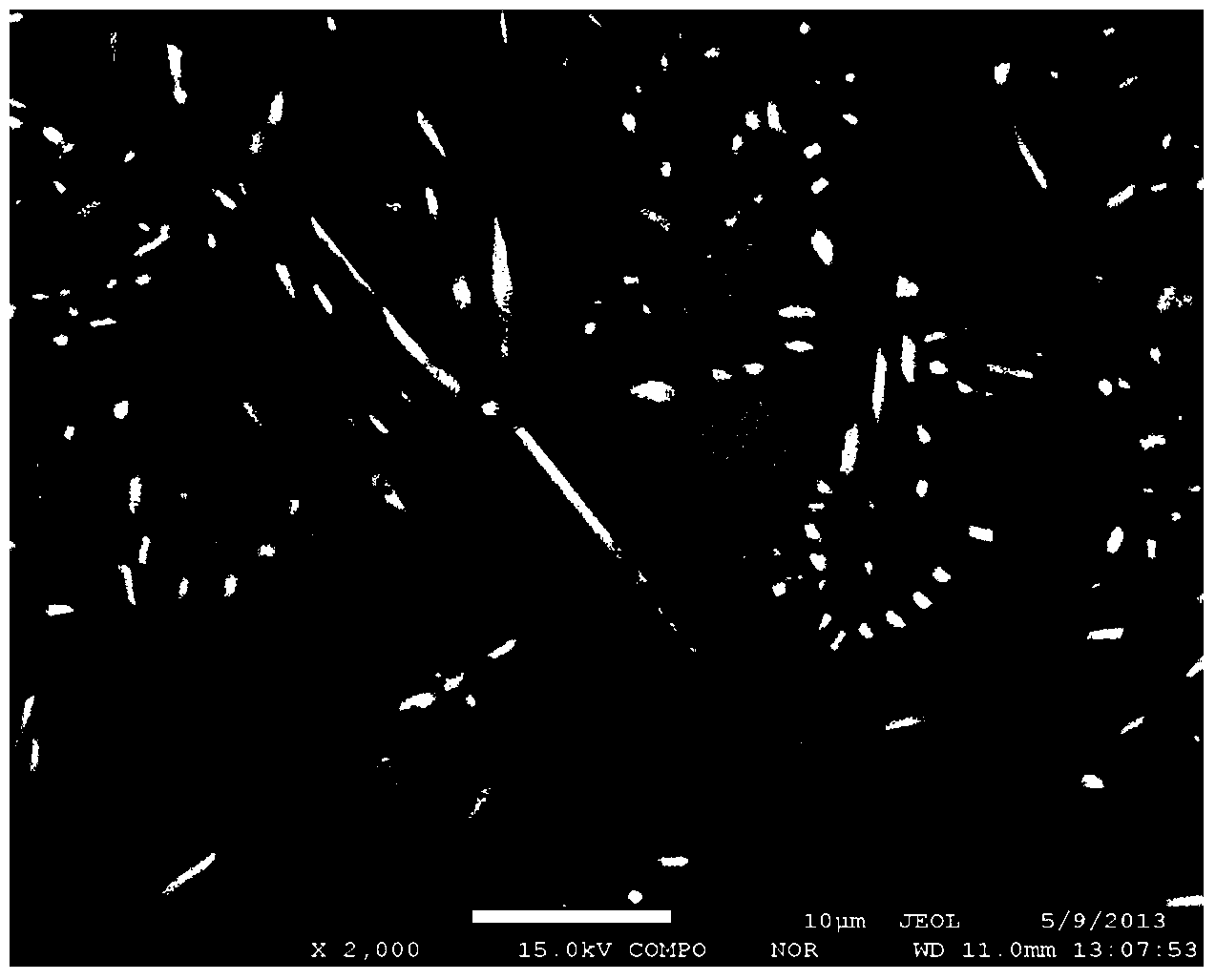

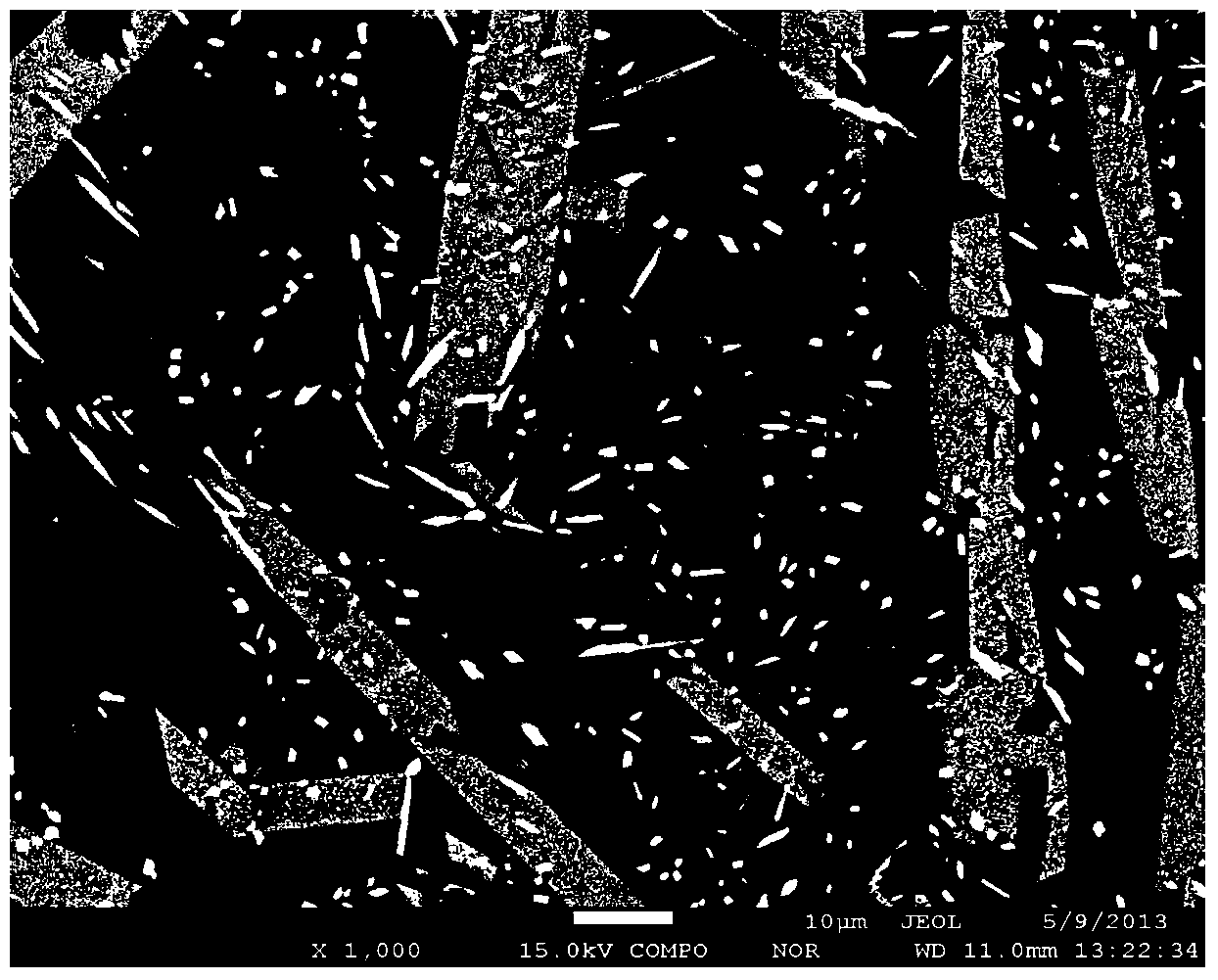

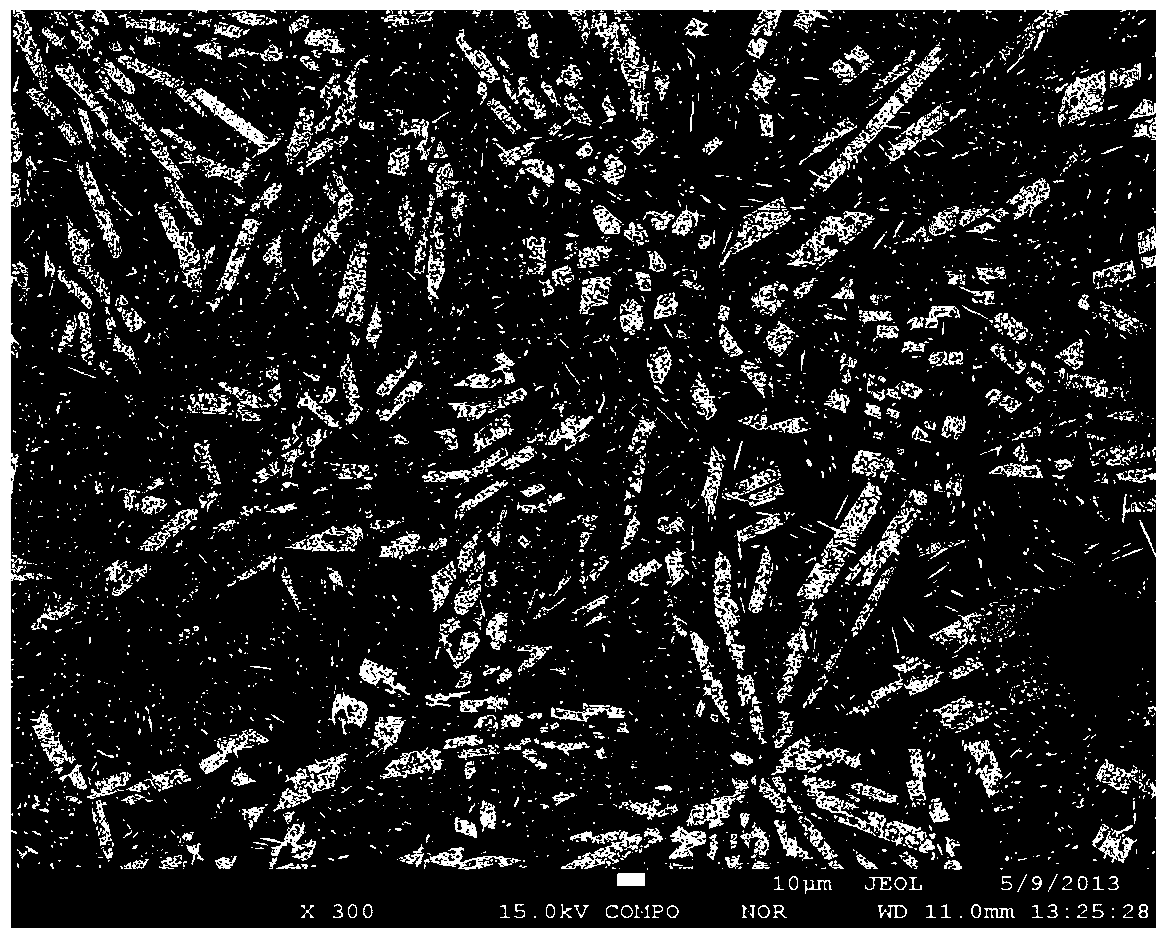

[0053] The X-ray diffraction pattern shows that the prepared glass-ceramic contains two crystal phases of wollastonite and ...

Embodiment 3

[0057] Embodiment 3 is based on Embodiment 1, the mixing ratio of wollastonite frit and apatite frit is changed to 8:2, the ratio of the two frits and the melting conditions remain unchanged, the mixing sintering heating rate, The sintering temperature and time remained unchanged.

[0058] Wollastonite glass-ceramic frit is made by melting the following raw materials in parts by weight: SiO 2 67.5 parts, CaO20 parts, Na 2 O12.5 parts; Apatite glass-ceramic frit is formed by melting the raw materials of following parts by weight: SiO 2 46 copies, Al 2 o 3 3.3 parts, CaO10 parts, BaO2 parts, MgO3.6 parts, B 2 o 3 2 parts, Na 2 O+K 2 O13 parts, CaF 2 0.6 parts, P 2 o 5 4.5 parts, ZnO3 parts, Sb 2 o 3 1 serving.

[0059] The X-ray diffraction pattern shows that the prepared glass-ceramic contains two crystal phases of wollastonite and apatite. The bending strength tested on the WDW3100 electronic universal testing machine is 95.7MPa, and the bending strength tested on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com