Thermoplastic cellular board and production method thereof, and double-steel-strip continuous press

A double steel strip, thermoplastic technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of inability to dissipate cooling in time, long hot pressing process time, damage to honeycomb structure, etc., and achieve good surface quality, The effect of stable honeycomb structure, improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

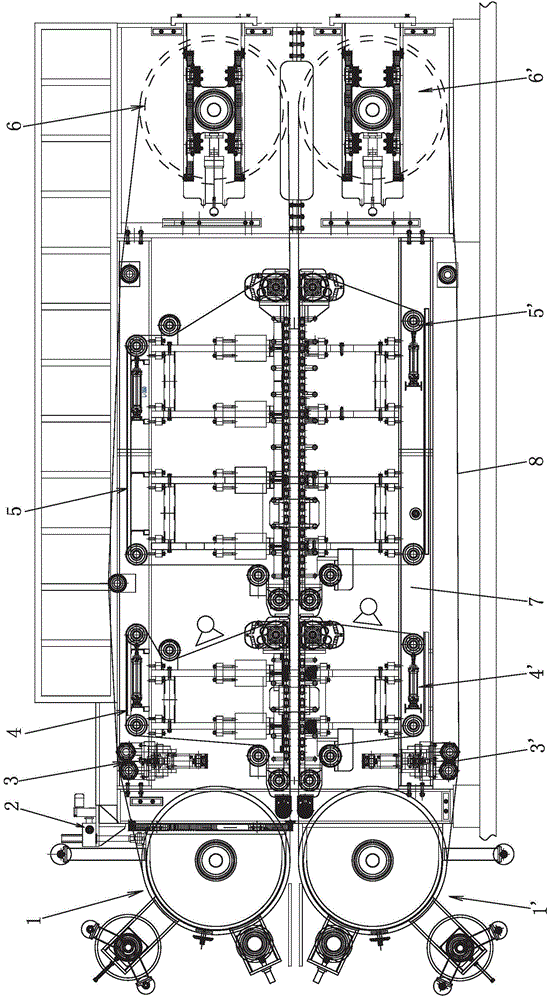

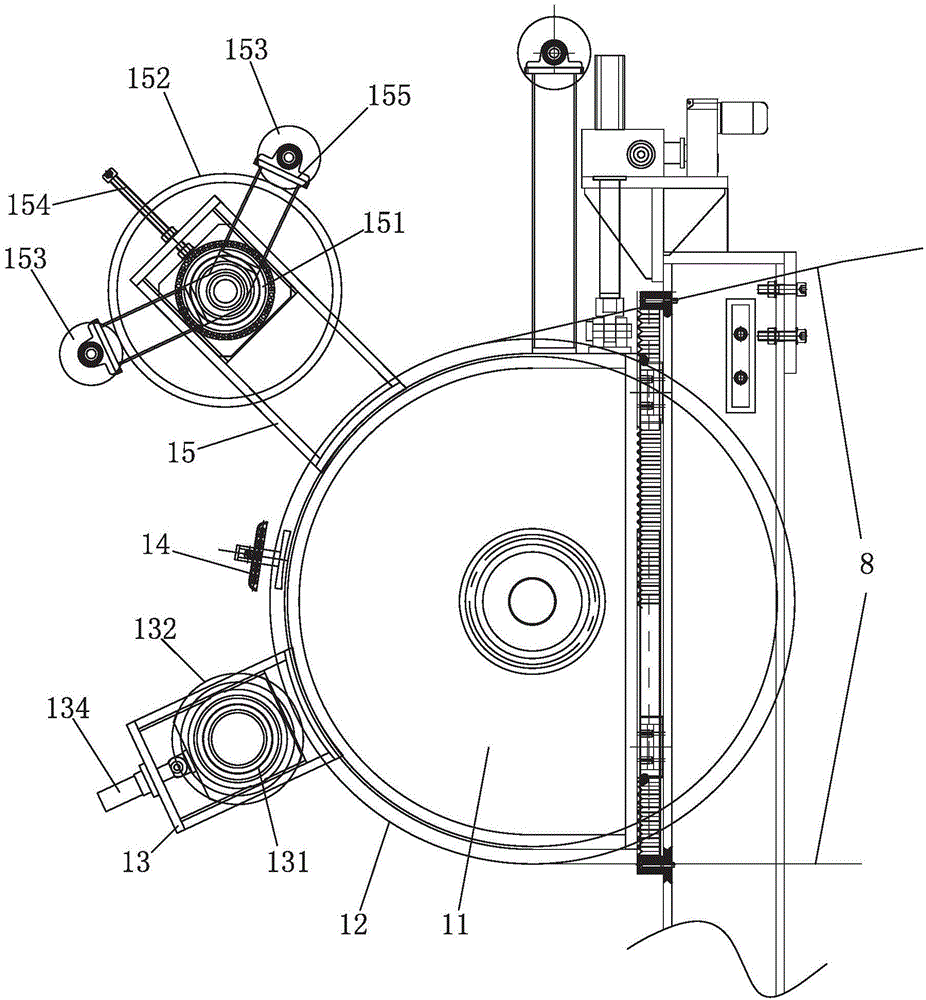

[0042] Such as figure 1 The shown is a double-steel-belt continuous press for producing thermoplastic honeycomb panels, including a frame 7 and corresponding upper and lower preheating mechanisms 1, 1', steel belt mechanisms 3, 3', roller blanket mechanisms and cooling and setting mechanism.

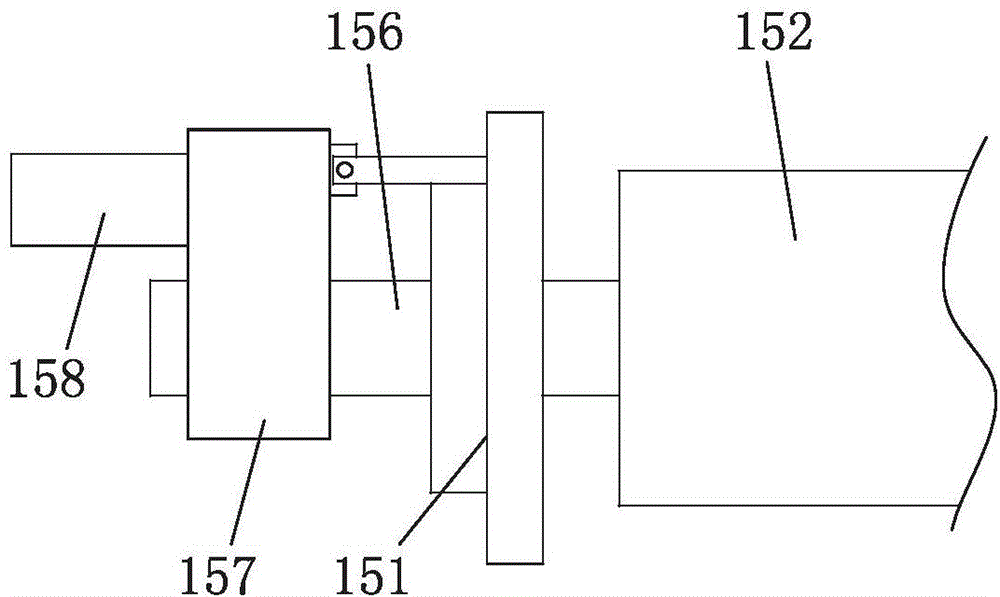

[0043] Described steel belt mechanism is divided into two correspondingly arranged up and down, and each steel belt mechanism all comprises the driven roller 12 that is positioned at frame 7 front end, the driving roller 6 that is positioned at frame 7 rear end and wraps around driven roller 12 and The steel belt 8 on the driving roller 6, the gap between the upper and lower two steel belts 8 is the plate conveying space. Such as Figure 4 As shown, the bearing seat 61 of the driving roller 6 is connected to the frame 7 through a horizontal sliding guide rail, and the driving cylinder 62 installed on the frame 7 drives the bearing seat 61 of the driving roller 6 to move back and forth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com