Method for preparing semen cannabis protein powder from degreased semen cannabis residue

A technology of hemp seed and protein powder is applied to the development technology of hemp and its application field, and achieves the effects of high efficiency, reduced production energy consumption, and simplified technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

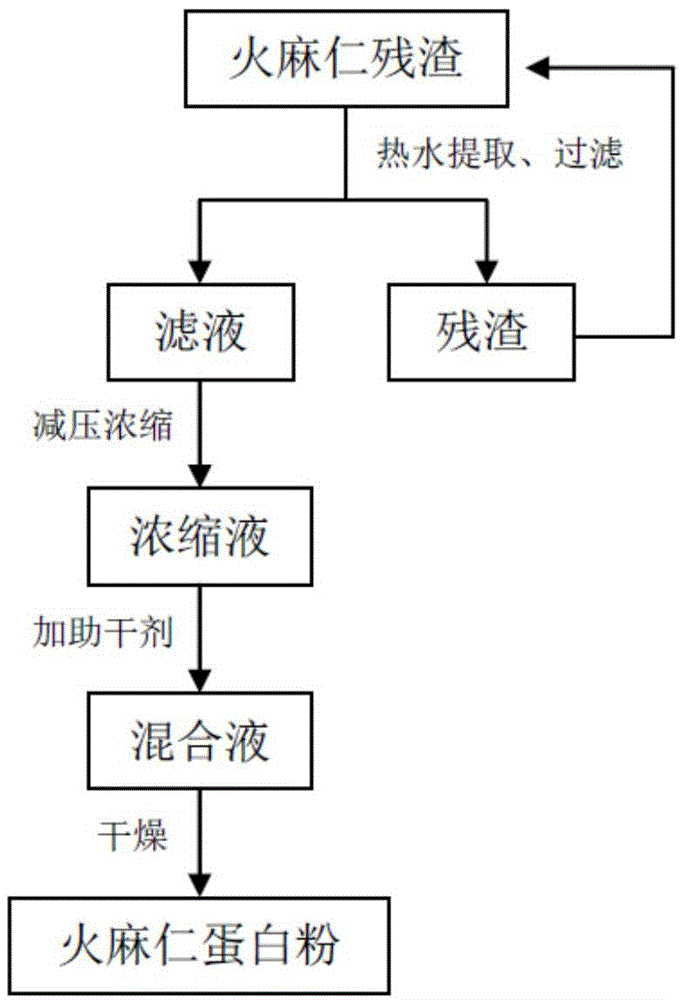

Image

Examples

Embodiment 1

[0033] (1) Weigh 50g of hemp seed residue, extraction process: feed the residue into the extraction tank, add 4 times the weight of hot water at 50°C to the extraction tank as the extractant, stir and extract at a constant temperature of 50°C for 1 hour , filtered, and the filtrate was placed in a concentration tank to collect the residue.

[0034] (2) Repeat the above step (1) leaching process once, and combine the filtrate in the concentration tank.

[0035] (3) Concentrate the filtrate in the concentration tank in step (2) at 55°C under reduced pressure to a concentrate with a relative density of 1.10 (measured value at 55°C), and accurately weigh the total weight of the concentrate to be 12.81g.

[0036] (4) Accurately weigh 2g of the concentrate, put it in a clean evaporating dish that has been dried to constant weight, evaporate to dryness in a water bath, dry in an oven at 105°C for 3 hours, take it out, cool it in a desiccator for 30 minutes to constant weight, and acc...

Embodiment 2

[0041] (1) Weigh 50g of hemp seed residue, extraction process: feed the residue into the extraction tank, add 6 times the weight of hot water at 70°C to the extraction tank as the extractant, stir and extract at a constant temperature of 70°C for 2 hours , filtered, and the filtrate was placed in a concentration tank to collect the residue.

[0042] (2) Repeat the above step (1) extraction process twice, and combine the filtrate in the concentration tank.

[0043] (3) Concentrate the filtrate in the concentration tank in step (2) at 60°C under reduced pressure to a concentrate with a relative density of 1.10 (measured value at 60°C), and accurately weigh the total weight of the concentrate to be 13.67g.

[0044] (4) Accurately weigh 2g of the concentrate, put it in a clean evaporating dish that has been dried to constant weight, evaporate to dryness in a water bath, dry in an oven at 105°C for 3 hours, take it out, cool it in a desiccator for 30 minutes to constant weight, and...

Embodiment 3

[0049] (1) Weigh 50g of hemp seed residue, extraction process: feed the residue into the extraction tank, add 8 times the weight of hot water at 90°C to the extraction tank as the extractant, stir and extract at a constant temperature of 90°C for 3 hours , filtered, and the filtrate was placed in a concentration tank to collect the residue.

[0050] (2) Repeat the above step (1) leaching process once, and combine the filtrate in the concentration tank.

[0051] (3) Concentrate the filtrate in the concentration tank in step (2) at 65°C under reduced pressure to a concentrate with a relative density of 1.12 (measured value at 65°C), and accurately weigh the total weight of the concentrate to be 13.16g.

[0052] (4) Accurately weigh 2g of the concentrate, put it in a clean evaporating dish that has been dried to constant weight, evaporate to dryness in a water bath, dry in an oven at 105°C for 3 hours, take it out, cool it in a desiccator for 30 minutes to constant weight, and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com