Energy-saving gas stove

A gas stove, energy-saving ring technology, applied in heating fuels, household stoves/stoves, stove/stove tops, etc., can solve the problems of heat use environment temperature rise, loss of energy utilization efficiency, and adverse health of users, etc. Achieve the effect of increasing heat exchange time, preventing heat transfer to the outside, and reducing the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

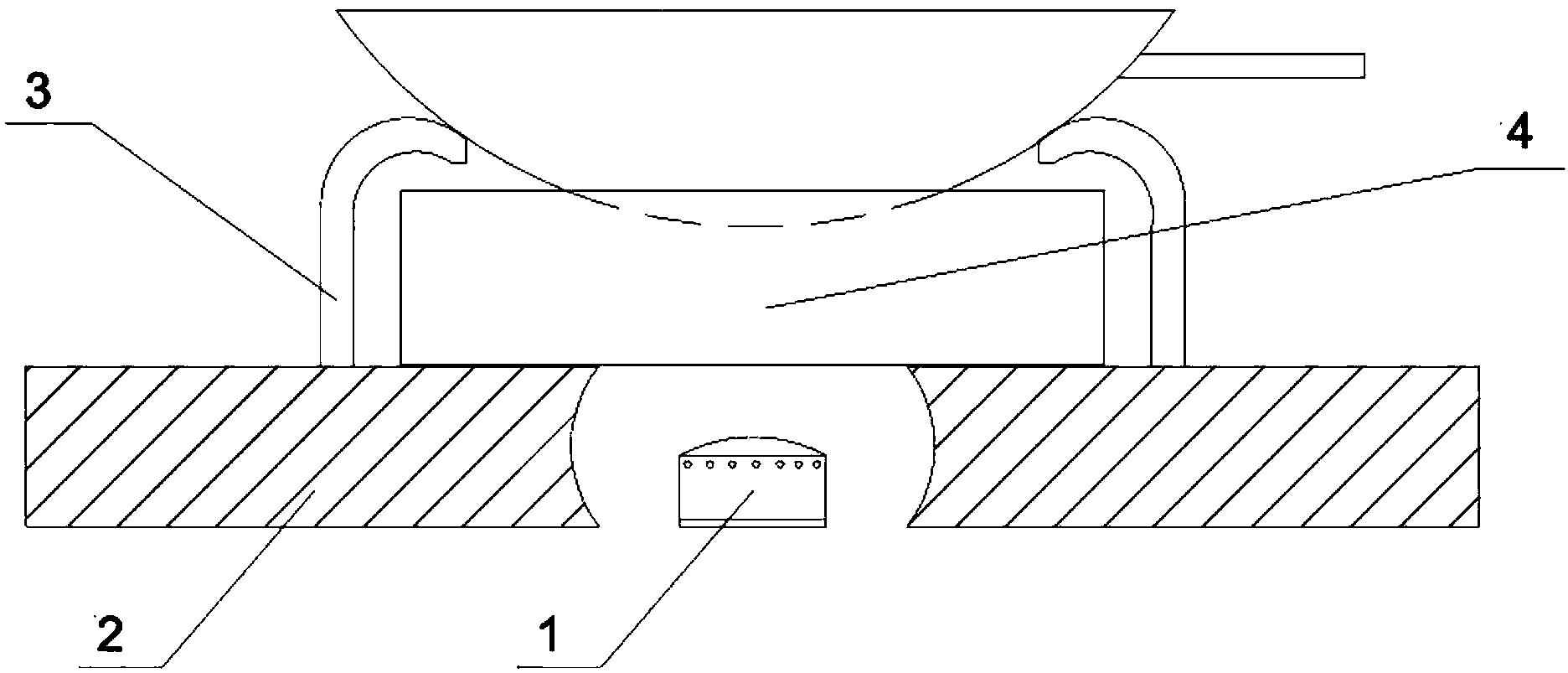

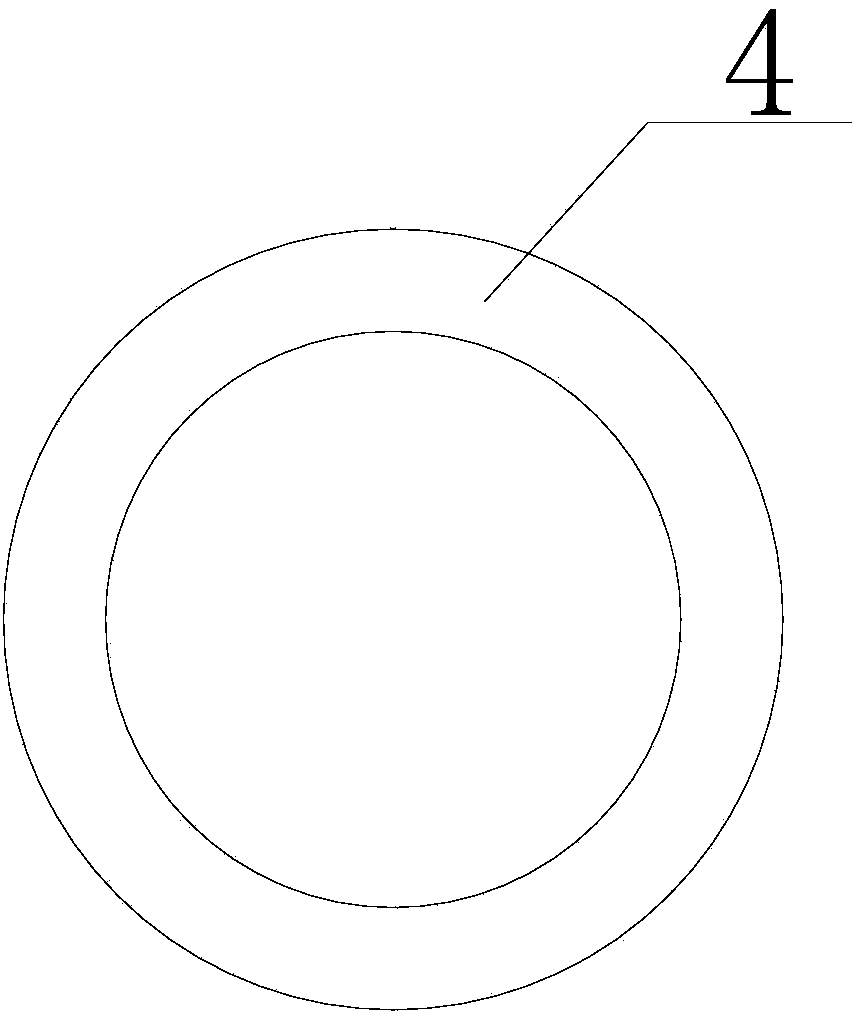

[0026] Such as figure 1 with figure 2 As shown, an energy-saving gas stove includes a stove top 1, a gas stove panel 2, a bracket 3 and an energy-saving ring 4. For the bracket 3 that supports the pot, an annular energy-saving ring 4 is installed on the inner ring of the bracket 3. The height of the energy-saving ring 4 is lower than the bracket 1, so that the pot can be smoothly placed in the pot bracket and removed from the pan bracket. Take it out, and leave a certain distance between the energy-saving ring 4 and the bottom surface of the pot to ensure the circulation of the gas field. The energy-saving ring 4 is made of heat-resistant and heat-insulating material, which includes aluminum silicate ceramic fiber, and the heat-resistant and heat-insulating material is used to insulate heat radiation from spreading outwards, improve thermal efficiency, save energy and protect the environment, and reduce the impact of flames on the stove and Influenced by the temperature ris...

Embodiment 2

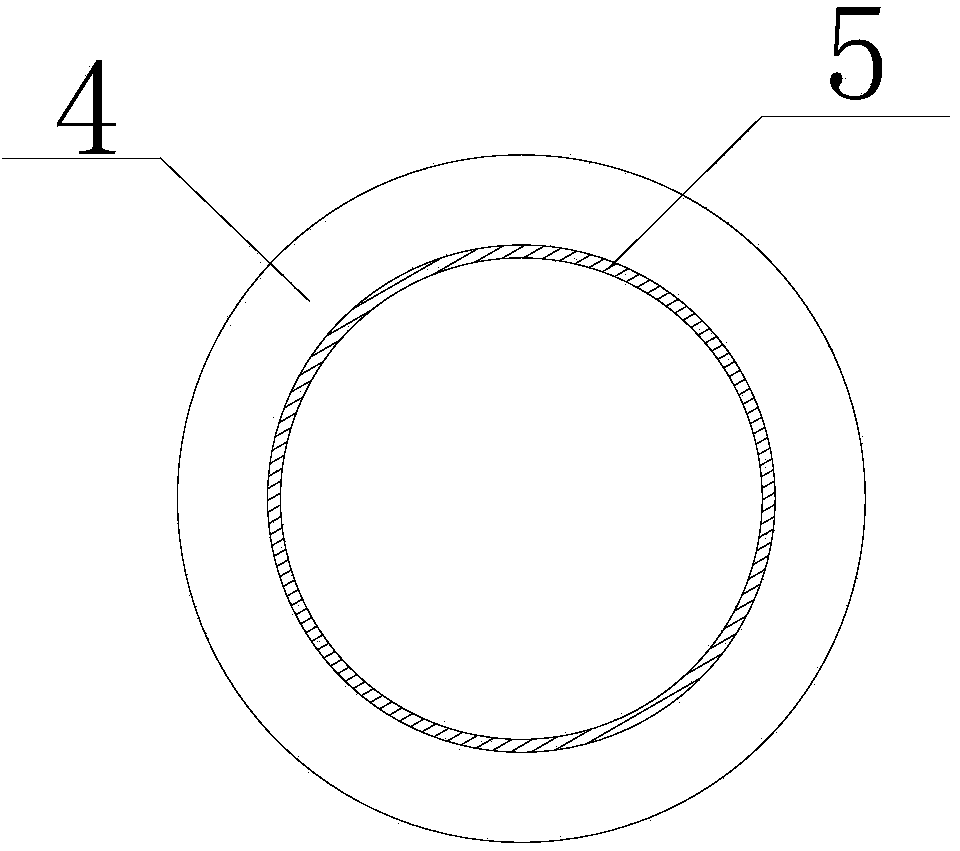

[0028] Such as image 3 As shown, a heat-resistant reflective layer 5 is provided on the inner ring of the annular energy-saving ring 4 made of heat-resistant and heat-insulating material, and the heat-resistant reflective layer 5 can concentrate the heat radiation energy and improve thermal efficiency.

Embodiment 3

[0030] Such as Figure 4 As shown, an energy-saving gas cooker includes a burner head 1, a gas cooker panel 2, a bracket 3 and an energy-saving ring 4, an annular energy-saving ring 4 is installed on the inner ring of the bracket 3, and a foot is provided at the bottom of the energy-saving ring 4 6 frames are installed on the gas cooker panel 2, the height of the energy-saving ring 4 is lower than the support 1, and there is a certain distance between the energy-saving ring 4 and the bottom surface of the pot.

[0031] Due to the function of the feet 6, a gap is formed between the energy-saving ring 4 and the panel 2 of the gas stove. This gap is a passage for supplementing combustion-supporting air, which can make the gas burn more fully, avoid the generation of carbon monoxide, improve the release of gas combustion energy, and improve thermal efficiency. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com