Perforation fracturing permeability-improvement method for high-stress low-porosity coal seam

A technology of porosity and high stress, which is applied in the direction of earthwork drilling, gas discharge, and mining fluids, etc., can solve the problems of intensive cross-drilling method with a large amount of work, little influence on the development of coal secondary fractures, and few micro-cracks. Achieve the effects of increasing the density and range of coal fractures, reducing the risk of coal and gas outburst, and increasing the density and range of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention discloses a perforation and fracturing anti-reflection method for high-stress and low-porosity coal seams. The present invention will be further clearly and completely described below in conjunction with an application example of the 1103 working face of a certain mine.

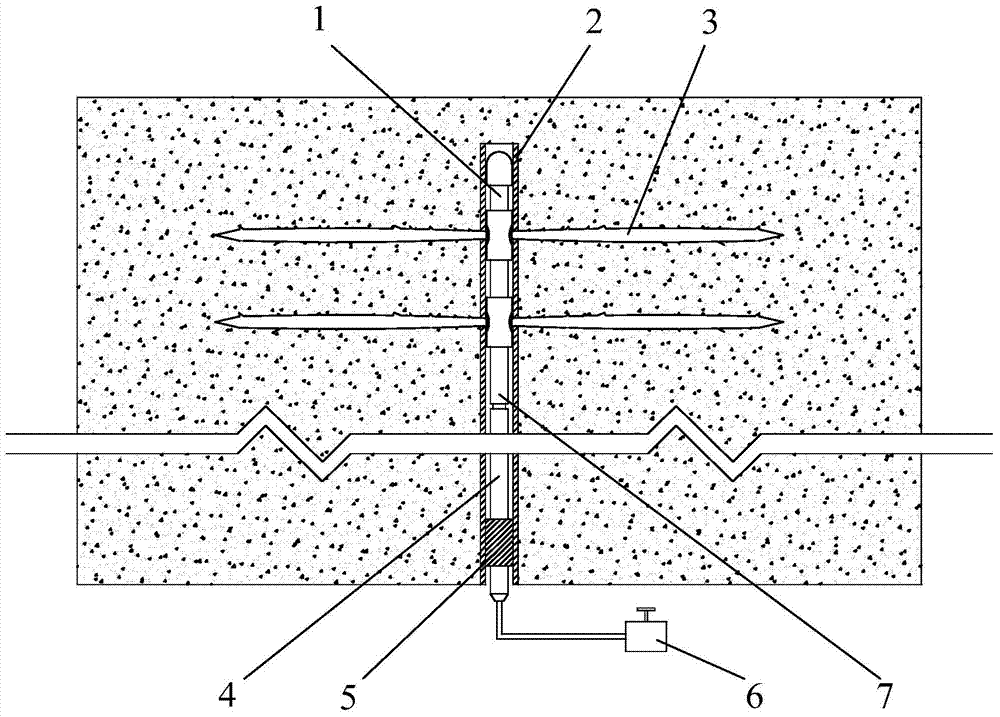

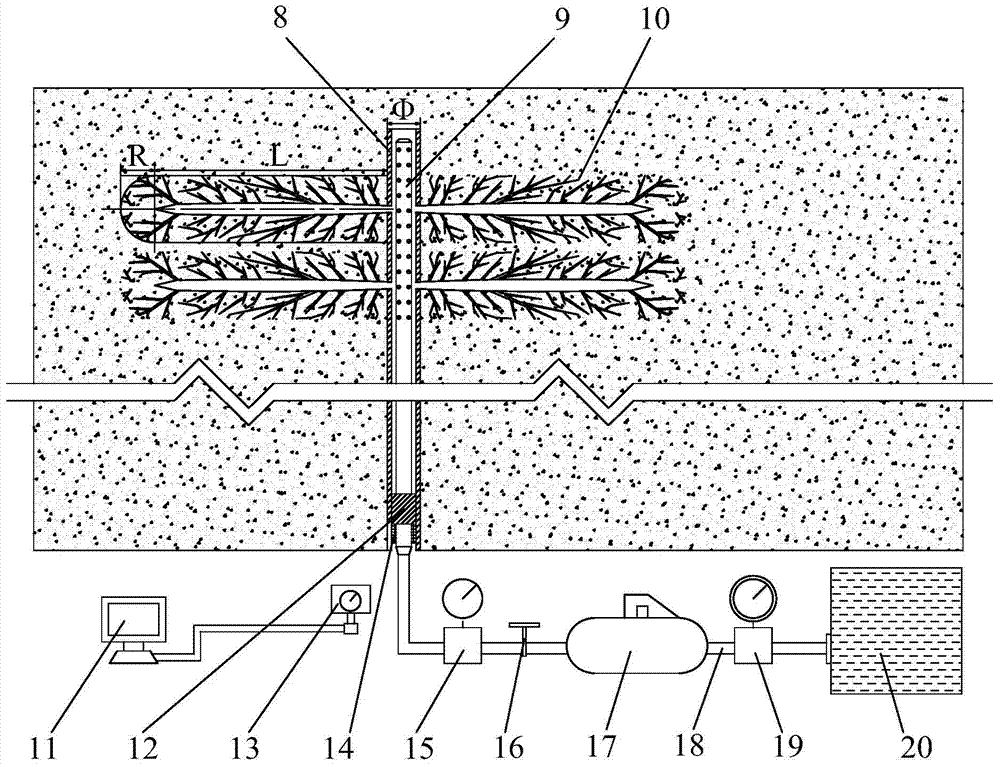

[0024] to combine figure 1 with figure 2 Shown, the present invention, a kind of high-stress low-porosity coal seam perforation fracturing anti-permeability method, comprises the following steps:

[0025] Step 1. Determination of coal mechanical properties

[0026] Coal samples were collected on site, industrial test and analysis of coal samples were carried out, and the physical and mechanical parameters of the coal body were measured. The measured mechanical parameters included: compressive strength, tensile strength, Poisson's ratio and elastic modulus. The test results are shown in Table 1 Working face The physical and mechanical parameters of coal body are shown in the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com