an iron driller

An iron driller and bracket technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of large thread damage of drilling tools, high labor intensity and narrow range of drilling tools, so as to avoid equipment replacement and maintenance. The number of times, the high degree of automation, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

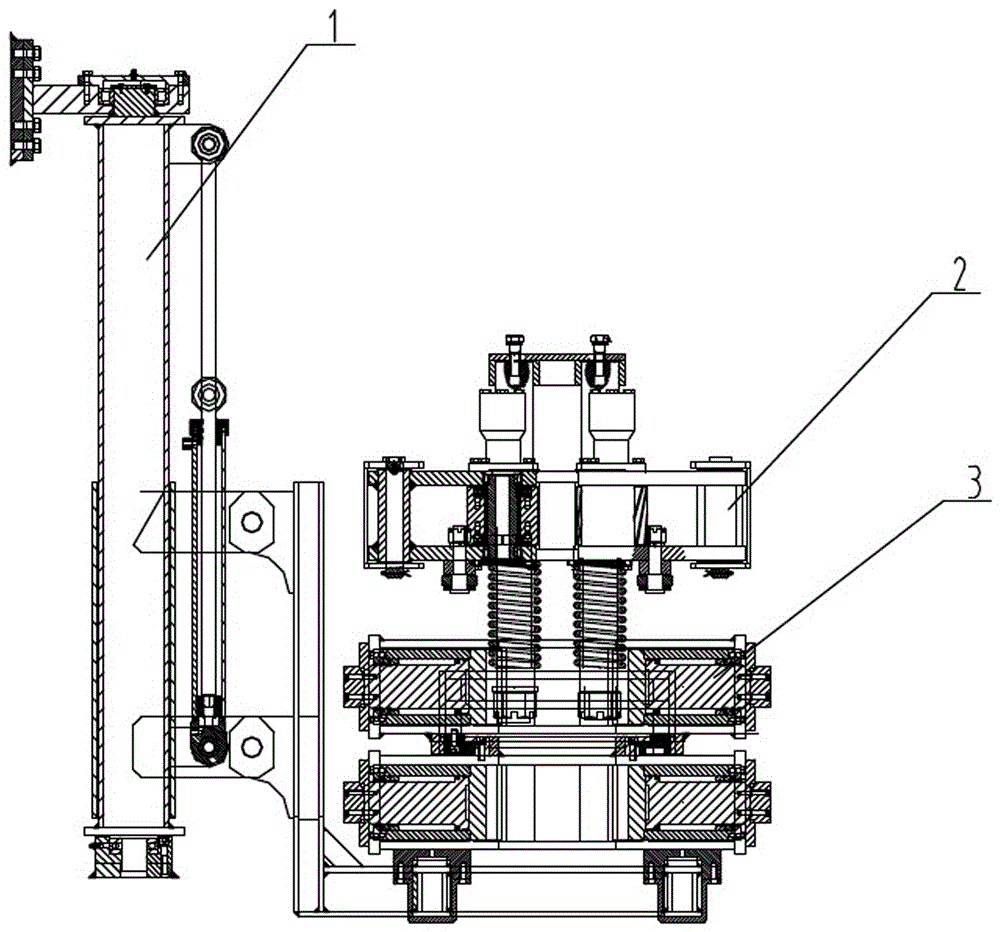

[0014] see figure 1 As shown, an iron driller includes a rotary bracket 1, a turnbuckle pliers 2 and a cracking pliers 3, the rotary bracket 1 carries the cracking pliers 3, and a twisting pliers is arranged above the cracking pliers 2.

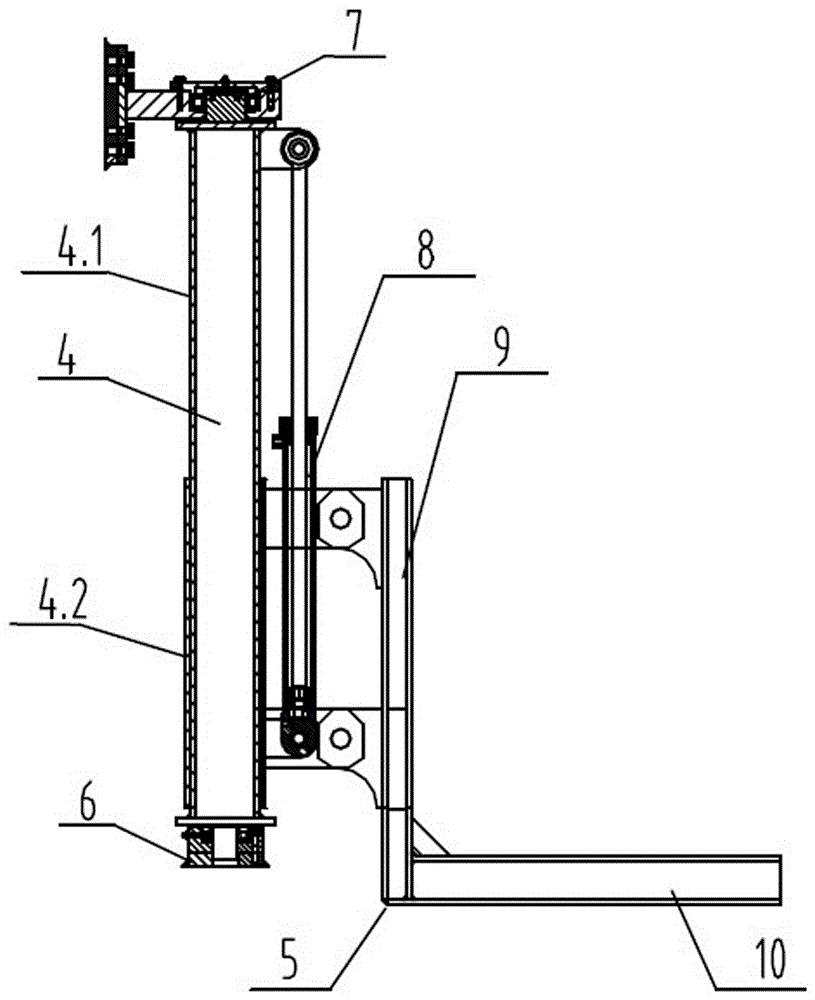

[0015] see figure 2 As shown, the rotary bracket of the iron driller includes: a column 4, an L-shaped bracket 5, a rotating base 6, a rotating gear 7, and a lifting hydraulic cylinder 8. The column 4 is composed of an inner square pipe 4.1 and an outer tube 4.2, the outer tube 4.2 is slidably sleeved on the outer wall of the inner tube 4.1, the upper and lower ends of the inner tube 4.1 are provided with a rotating base 6, and the upper end of the inner tube 4.1 is equipped with a rotating base 6 There is also a rotating gear 7 that can drive the inner square tube 4.1 to rotate. The L-shaped bracket 5 is composed of a vertical support plate 9 and a horizontal support plate 10. The vertical support plate 9 is fixed on the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com