An automatic uprighting device and method for inverted bottles in a production line

A self-righting and production line technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as dumping, self-righting without glass bottles, etc., to achieve the effect of automation and rapid action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

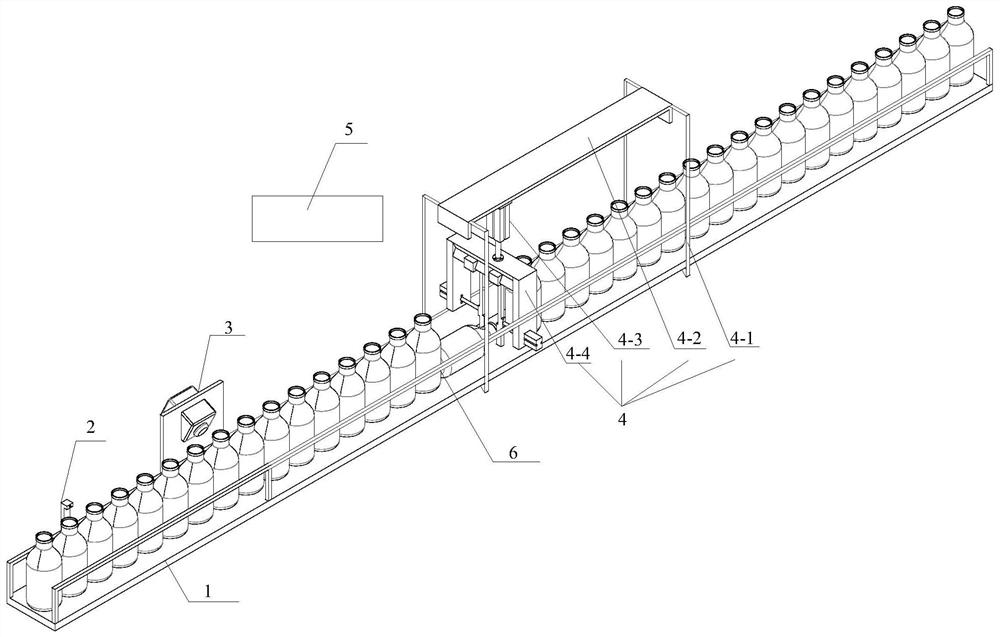

[0034] An automatic righting system for inverting bottles in a production line, comprising a conveyor belt 1, at least one set of automatic righting device is provided on the conveyor belt 1, and the automatic righting device includes photoelectric sensors 2 sequentially arranged on the conveyor belt 1 along the running direction of the conveyor belt 1 , industrial camera 3 and righting mechanism 4;

[0035] Described righting mechanism 4 comprises the support 4-1 that is arranged along the running direction of conveyor belt, is provided with sliding guide unit 4-2 between support 4-1, and the lower part of sliding guide unit 4-2 is provided with lifting unit 4-3, and lifting unit The lower part of 4-3 is connected with the righting unit 4-4;

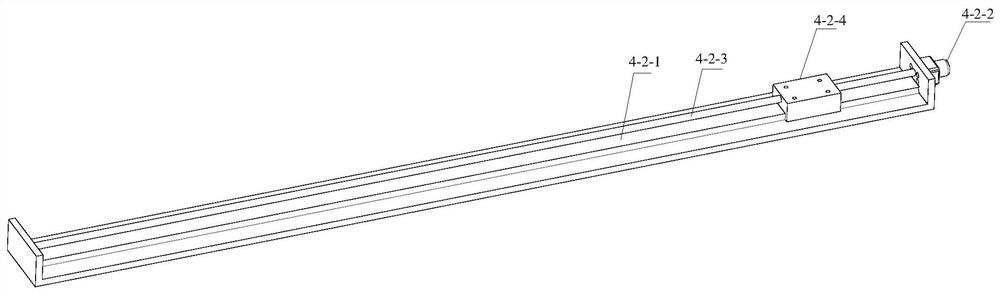

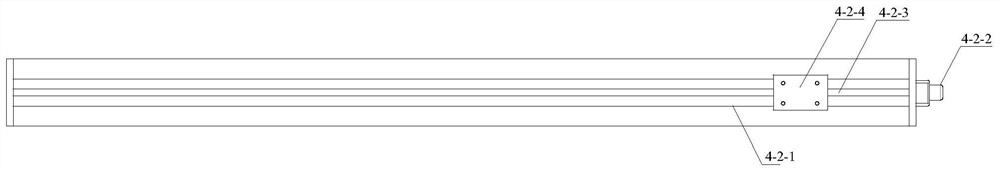

[0036] Described slide guide unit 4-2 comprises guide rail 14-2-1, servo motor 14-2-2 and the guide rod 4-2-3 that is connected with servo motor 14-2-2, on the guide rod 4-2-3 There is a slider I4-2-4, and the slider I4-2-4 cooperates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com