Drilling tool salvaging device

A salvage device and drilling tool technology, which is applied to earth-moving drilling, wellbore/well components, etc., can solve problems such as time-consuming, difficult salvage methods, and easy deflection of drilling tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

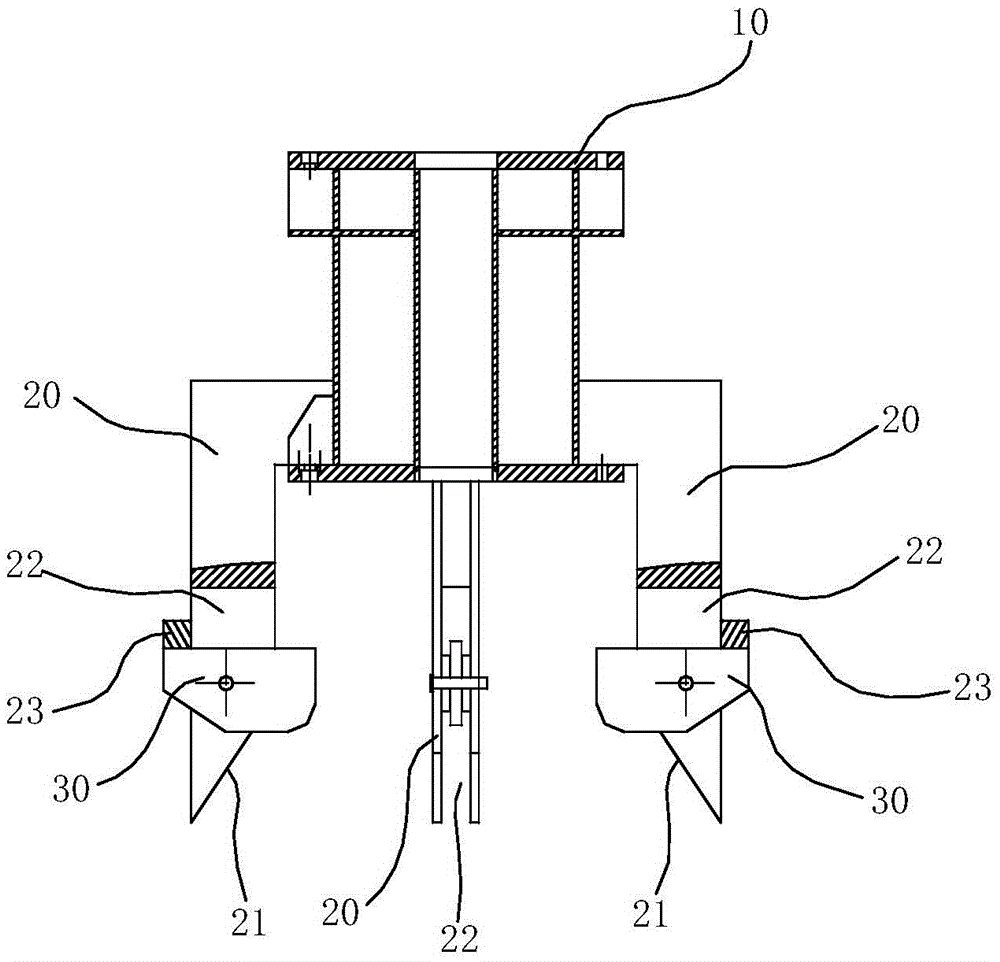

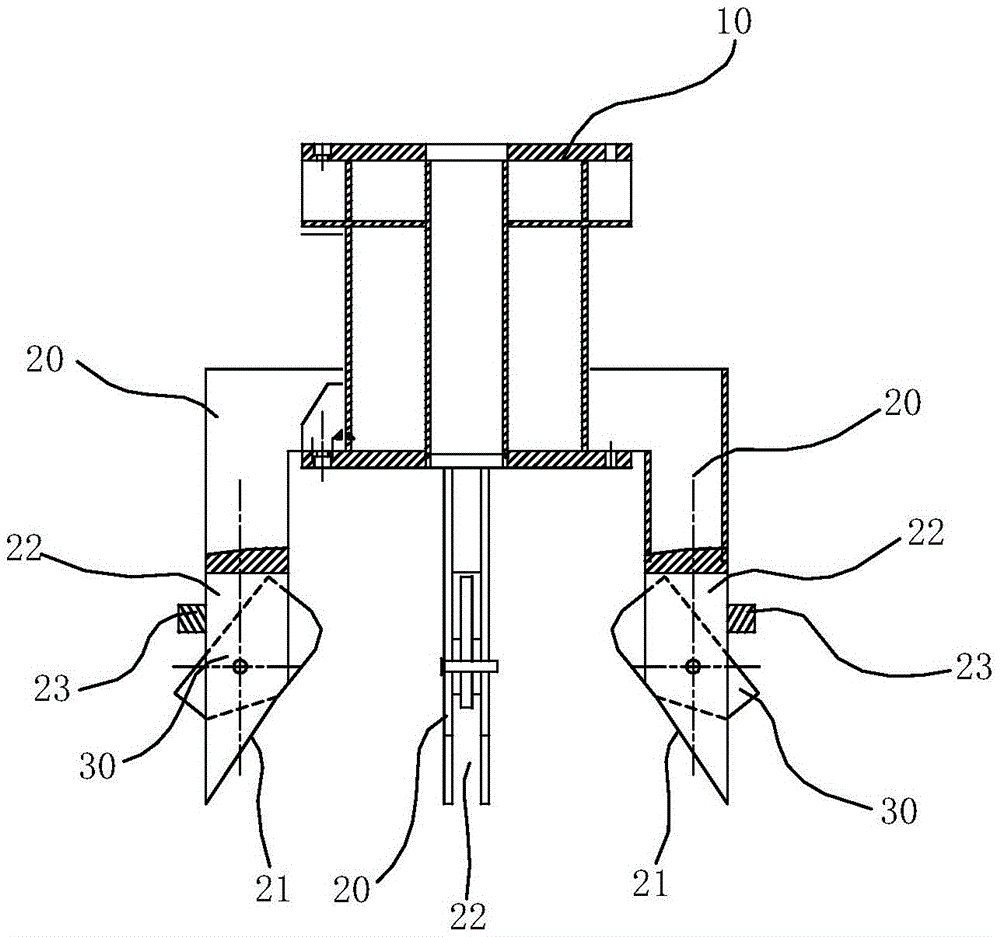

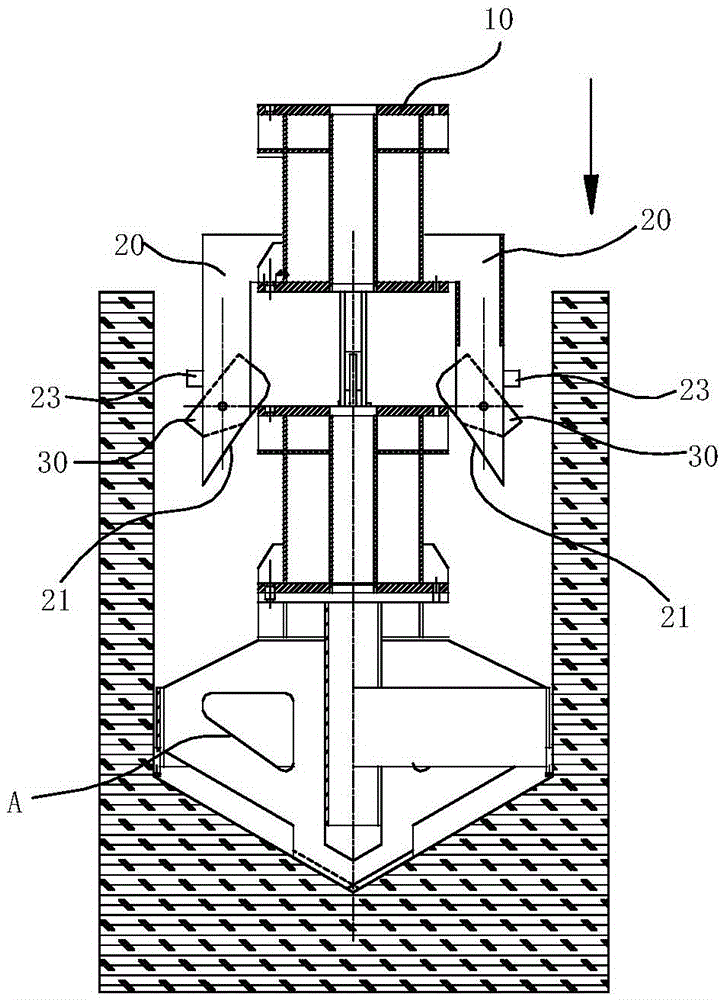

[0010] combine Figure 1 to Figure 5 , to further illustrate the present invention

[0011] A drilling tool fishing device, comprising a counterweight plate 10, on which a cantilever 20 is distributed, and the cantilever 20 extends downward and parallel to the extending direction, and the area enclosed by the extension ends of the lower ends of the plurality of cantilevers 20 constitutes For the accommodation cavity of the drilling tool A to be salvaged, the lower extension end of the cantilever 20 is provided with a supporting part, and the supporting part is located on the cantilever 20 to accommodate and support the drilling tool A to be salvaged. The outer wall is also in two elevated positions. The counterweight plate 10 is connected to a lifting rod, and the lifting rod drives the lifting action of the counterweight plate 10 .

[0012] Abandon the disadvantages brought by the salvage method of using the salvage rope and the hook in the prior art, and use the lifting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com