Construction method for fast assembling precast concrete panels to reinforce underwater structure

A prefabricated concrete and underwater structure technology, which is applied in the direction of underwater structures, foundation structure engineering, foundation structure repair, etc., can solve the problems of material performance waste, high cost, long cycle, etc., and achieve the goal of reducing secondary stress impact, simple construction process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

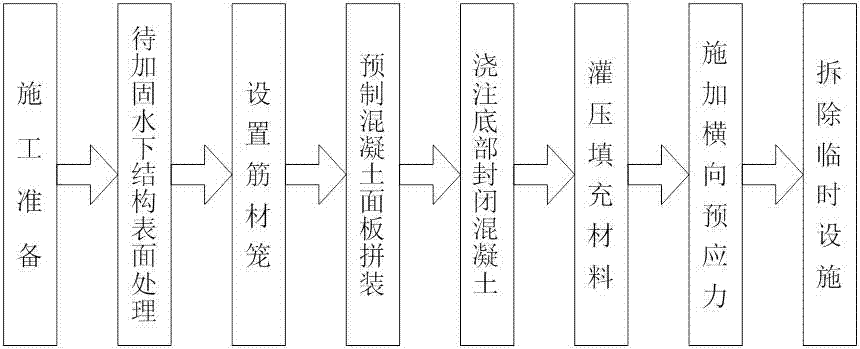

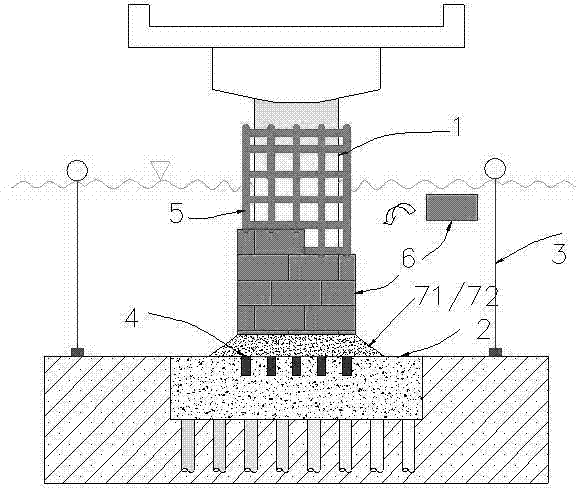

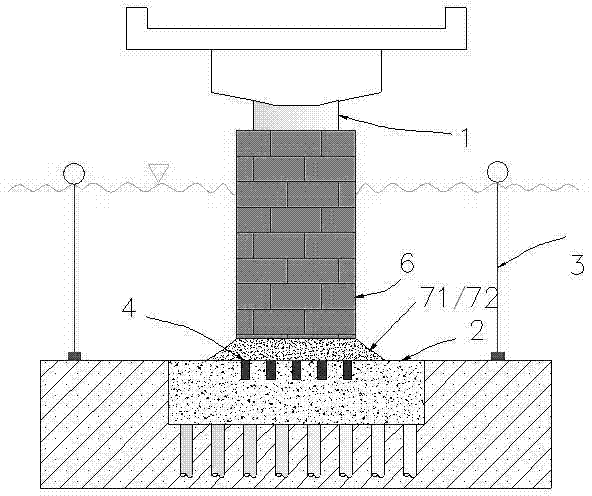

[0049] Such as figure 1 As shown, the construction method of prefabricated concrete panel fast assembling and strengthening underwater structure of the present invention comprises the following steps:

[0050] Preparatory work, in order to prevent the reinforcement process from polluting the surrounding waters, set up pollution prevention membranes in the construction area, and set up temporary facilities such as working platforms for water construction;

[0051] Structural surface treatment, using high-speed water spray guns, etc. to remove attachments on the surface of the underwater structure to be reinforced and perform other necessary structural surface treatment;

[0052] Set up a reinforcement cage, and set a reinforcement cage on the surface of the underwater structure to be reinforced according to the needs of the reinforcement target;

[0053] Panel assembly, where factory prefabricated concrete panels are assembled on site around the underwater structure to be rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com