Cold-rolled hot-galvanized dual-phase steel and preparation method thereof

A hot-dip galvanized, dual-phase steel technology, which is applied in the field of cold-rolled hot-dip galvanized dual-phase steel, can solve the problems of hot-dip galvanized dual-phase steel welding performance and stamping performance, lower galvanizing quality, unfavorable martensite, etc. problem, to achieve the effect of reducing the strength difference, improving the performance of flange flanging, and improving the performance of flange extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

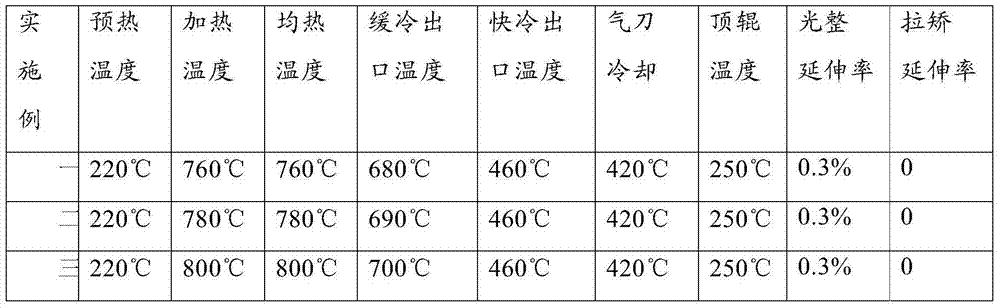

Embodiment 1

[0026] The cold-rolled hot-dip galvanized dual-phase steel used in this embodiment and its preparation method comprise the following steps:

[0027] (1) The molten steel is smelted in a converter, and the continuous casting billet is obtained by continuous casting;

[0028] (2) hot-rolling the continuous casting slab to obtain a hot-rolled plate, and further cold-rolling the hot-rolled plate to obtain a chilled steel strip;

[0029] (3) The above-mentioned chilled steel strip is subjected to a continuous galvanizing and annealing process to obtain a finished product.

[0030] During the smelting process: (1) Control the end point temperature of converter smelting: first furnace 1658°C, continuous pouring furnace 1645-1665°C; (2) Use Al-Fe for deoxidation; use Mn-Fe with Mn, use Cr-Fe with Cr; The amount of slag under tapping is ≤80mm, and the tapping time is ≥4 minutes; the slagging agent is added during the tapping process, and the slag is added at the early stage of tapping...

Embodiment 2

[0032] The cold-rolled hot-dip galvanized dual-phase steel used in this embodiment and its preparation method comprise the following steps:

[0033] (1) The molten steel is smelted in a converter, and the continuous casting billet is obtained by continuous casting;

[0034] (2) hot-rolling the continuous casting slab to obtain a hot-rolled plate, and further cold-rolling the hot-rolled plate to obtain a chilled steel strip;

[0035] (3) The above-mentioned chilled steel strip is subjected to a continuous galvanizing and annealing process to obtain a finished product.

[0036] During the smelting process: (1) Control the end temperature of converter smelting: first furnace 1665°C, continuous casting furnace 1645-1665°C; (2) Use Al-Fe for deoxidation; use Mn-Fe with Mn, use Cr-Fe with Cr; The amount of slag under tapping is ≤80mm, and the tapping time is ≥4 minutes; the slagging agent is added during the tapping process, and the slag is added at the early stage of tapping, and ...

Embodiment 3

[0038] The cold-rolled hot-dip galvanized dual-phase steel used in this embodiment and its preparation method comprise the following steps:

[0039] (1) The molten steel is smelted in a converter, and the continuous casting billet is obtained by continuous casting;

[0040] (2) hot-rolling the continuous casting slab to obtain a hot-rolled plate, and further cold-rolling the hot-rolled plate to obtain a chilled steel strip;

[0041] (3) The above-mentioned chilled steel strip is subjected to a continuous galvanizing and annealing process to obtain a finished product.

[0042] During the smelting process: (1) Control the end temperature of converter smelting: first furnace 1667°C, continuous pouring furnace 1645-1665°C; (2) Use Al-Fe for deoxidation; use Mn-Fe with Mn, use Cr-Fe with Cr; The amount of slag under tapping is ≤80mm, and the tapping time is ≥4 minutes; the slagging agent is added during the tapping process, and the slag is added at the early stage of tapping, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com