Ester solvent environment-friendly thermoplastic acrylic coating and preparation method thereof

A thermoplastic acrylic, ester solvent technology, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

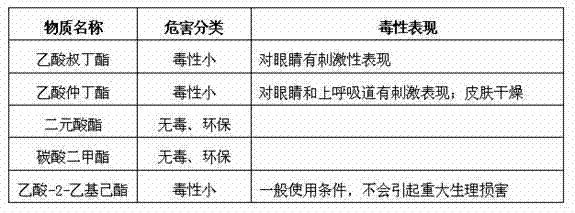

Method used

Image

Examples

Embodiment 1

[0105] First, 10 kg of tert-butyl acetate, 20 kg of sec-butyl acetate, 20 kg of dibasic acid ester, and 20 kg of dimethyl carbonate are uniformly mixed in proportion through a high-speed disperser and configured as an "ester solvent". The speed is: 650 ~1450 rpm, the time is 5 minutes; then "ester solvent", high solid content (solid content ≥ 60%), 90 kg of aromatic-free thermoplastic acrylic resin, 25 kg of rutile titanium dioxide, silica filler 5 kg, 5 kg of additives (one or more of wetting dispersant, defoamer, thickener, antifouling and antifungal agent), uniformly mixed by a high-speed disperser for 10 minutes; the mixture is sand-milled Machine grinding twice, each time is 0.5 hours; finally, pour 4 kg of 2-ethylhexyl acetate solvent into it, after uniform stirring, grind for 1 hour again, and the finished product can be obtained when the fineness reaches below 25 μm.

Embodiment 2

[0107] Firstly, 15 kg of tert-butyl acetate, 25 kg of sec-butyl acetate, 25 kg of dibasic acid ester, and 25 kg of dimethyl carbonate are uniformly mixed in proportion by a high-speed disperser to form an "ester solvent". The speed is: 650 ~1450 rpm, the time is 5 minutes; then add "ester solvent", high solid content (solid content ≥ 60%), 120 kg of aromatic-free thermoplastic acrylic resin, 35 kg of rutile titanium dioxide, silica filler 8 kg, 6 kg of additives (one or more of wetting dispersant, defoamer, thickener, antifouling and antifungal agent) are uniformly mixed by a high-speed disperser for 10 minutes; the mixture is passed through a sand mill Grind twice, each time for 1 hour; finally, pour 6 kg of 2-ethylhexyl acetate solvent into it, stir evenly, and grind for 1 hour again, and the finished product can be obtained when the fineness reaches below 25 μm.

Embodiment 3

[0109] Firstly, 20 kg of tert-butyl acetate, 30 kg of sec-butyl acetate, 30 kg of dibasic acid ester, and 30 kg of dimethyl carbonate are uniformly mixed in proportion by a high-speed disperser and configured as an "ester solvent". The speed is: 650 ~1450 rpm, the time is 5 minutes; then "ester solvent", high solid content (solid content ≥ 60%), 150 kg of aromatic-free thermoplastic acrylic resin, 50 kg of rutile titanium dioxide, silica filler 10 kg, 8 kg of additives (one or more of wetting dispersant, defoamer, thickener, antifouling and antifungal agent) are uniformly mixed by a high-speed disperser for 10 minutes; the mixture is passed through a sand mill Grind twice, each time for 1.5 hours; finally, pour 8 kg of 2-ethylhexyl acetate solvent into it, stir evenly, and grind for 1 hour again, and the finished product can be obtained when the fineness reaches below 25 μm.

[0110]

[0111]

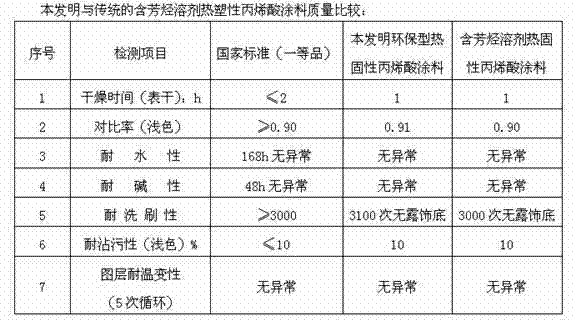

[0112] In the present invention, the thermoplastic acrylic paint produced by su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com