Welding rod printing pigment and preparation method thereof

A printing and pigment technology, applied in the field of welding rod printing pigment and its preparation, can solve the problems of light fastness, heat resistance, poor weather resistance, occupational health hazards, etc., and achieve low cost, stable physical and chemical properties, and high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

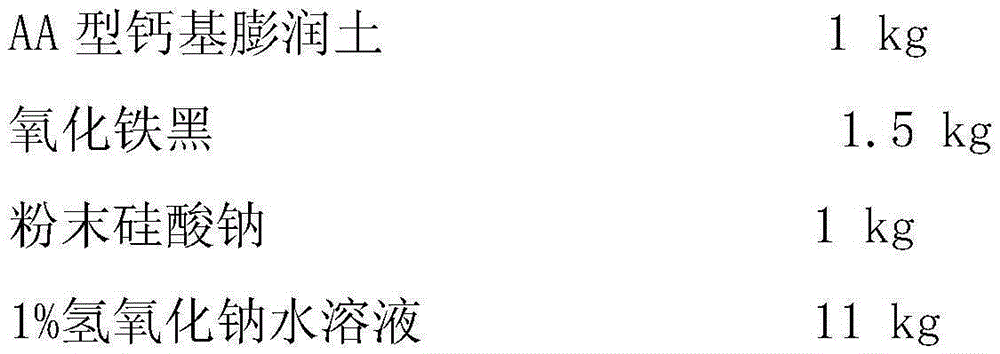

[0025] Weigh each raw material as follows:

[0026]

[0027] After the above raw materials are weighed, first mix AA-type calcium-based bentonite, iron oxide black, and powdered sodium silicate evenly, add 11kg of 1% sodium hydroxide aqueous solution as a diluent, mix well, and stir evenly. Then put the mixture into a colloid mill to grind to obtain a paste-like black pigment with certain fluidity.

[0028] When the pigment is actually used, it meets the baking temperature of the welding rod and the temperature of the welding core and coating when the welding rod burns to the end. When the temperature set in the test reaches 800°C, after the welding rod is baked for 2 hours, the printed characters are still clearly visible without discoloration. Scratch resistant.

Embodiment 2

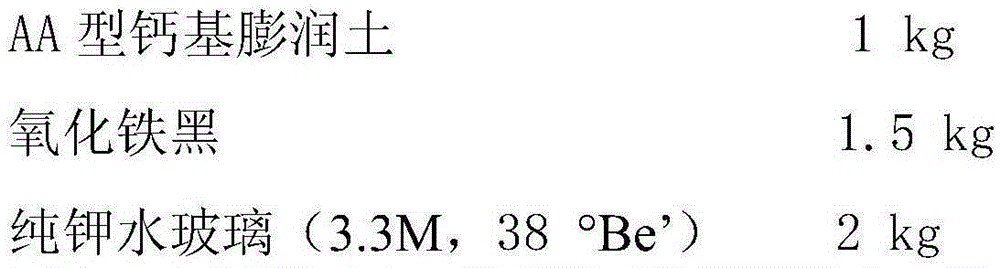

[0030] Weigh each raw material as follows:

[0031]

[0032]

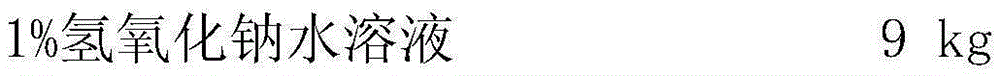

[0033] After weighing the above raw materials, dry mix AA-type calcium-based bentonite and iron oxide black evenly, then pour 2kg of pure potassium silicate (3.3M, 38°Be') and 9kg of 1% sodium hydroxide aqueous solution , mix well and stir well. Then put the mixture into a colloid mill to grind to obtain a paste-like black pigment with certain fluidity.

[0034] When the pigment is actually used, it meets the baking temperature of the welding rod and the temperature of the welding core and coating when the welding rod burns to the end. When the temperature set in the test reaches 800°C, after the welding rod is baked for 2 hours, the printed characters are still clearly visible without discoloration. Scratch resistant.

Embodiment 3

[0036] Weigh each raw material as follows:

[0037]

[0038] After weighing the above raw materials, dry mix AA-type calcium-based bentonite and iron oxide black evenly, then pour 2kg of pure potassium silicate (3.3M, 38°Be') and 9kg of 1% sodium hydroxide aqueous solution , mix well and stir well. Then put the mixture into a colloid mill to grind to obtain a paste-like black pigment with certain fluidity.

[0039] When the pigment is actually used, it meets the baking temperature of the welding rod and the temperature of the welding core and coating when the welding rod burns to the end. When the temperature set in the test reaches 800°C, after the welding rod is baked for 2 hours, the printed characters are still clearly visible without discoloration. Scratch resistance; in this case, the existing printing pigments will have blurred fonts and other phenomena.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com