A method for extracting resistant starch from rice wine lees with ultra-high pressure and ultrasonic assisted treatment

A technology for rice wine lees and resistant starch, which is applied in the field of comprehensive utilization of rice wine lees, can solve the problems of neglecting the research on starch properties and the development of application technology, and achieves the effect of solving the problem of waste resource utilization, strong operability and uniform products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

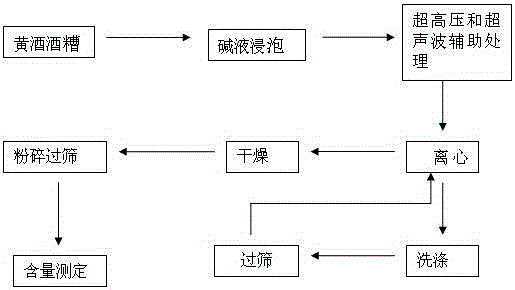

Image

Examples

Embodiment 1

[0017] (1) Soaking in lye: The rice wine distiller's grain sample used contains 20% starch, 38% protein and 1.8% lipid; weigh the rice wine distiller's grain powder, add deionized water according to the ratio of material to liquid 1:6, and add it to prepare 0.1M NaOH solution to adjust the pH to 8.5;

[0018] (2) Ultra-high pressure treatment: The mixed liquid obtained in step (1) is subjected to ultra-high pressure treatment, and the mixed liquid is subjected to ultra-high pressure 500MPa, 40°C for 20 minutes (Ultra-high pressure food preservation, Taiyuan Zhongping Technology);

[0019] (3) Ultrasonic treatment: take the mixed solution obtained in step (2) for ultrasonic treatment, ultrasonic frequency 40kHz, 500w treatment for 25min (ultrasonic extraction instrument JYC-LC, produced by Shanghai Juyuan Machinery), stirring for 3h, and standing for 12h;

[0020] (4) Centrifugal washing: centrifuge the mixture obtained in step (3) at a speed of 4000r / min for 30min (TDL-5(A) la...

Embodiment 2

[0024] (1) Soaking in lye: the used rice wine lees sample contains 20% starch, 36% protein and 1.7% lipid; weigh a certain amount of rice wine distiller grain powder, add deionized water according to the ratio of material to liquid 1:9, and then Add the prepared 0.1M NaOH solution to adjust the pH to 9.0;

[0025] (2) Ultra-high pressure treatment: The mixed liquid obtained in step (1) is subjected to ultra-high pressure treatment, and the mixed liquid is subjected to ultra-high pressure 550MPa, 35°C for 20 minutes (Ultra-high pressure food preservation, Taiyuan Zhongping Technology);

[0026] (3) Ultrasonic treatment: take the mixture obtained in step (2) for ultrasonic treatment, ultrasonic frequency 60kHz, 500w treatment for 25min (ultrasonic extraction instrument JYC-LC, produced by Shanghai Juyuan Machinery), stirring for 2.5h, and settling for 14h.

[0027] (4) Centrifugal washing: Centrifuge the mixture obtained in step (3) at a speed of 5000r / min for 30min (TDL-5(A) la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com