Method for preparing low-dielectric-constant microwave dielectric ceramic material

A technology of microwave dielectric ceramics and low dielectric constant, which is applied in the field of low-temperature co-fired ceramics in the field of endogenous porcelain powder preparation, which can solve problems such as difficult to meet price wars, and achieve superior secondary processing performance, cheap raw materials, and low dielectric constant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

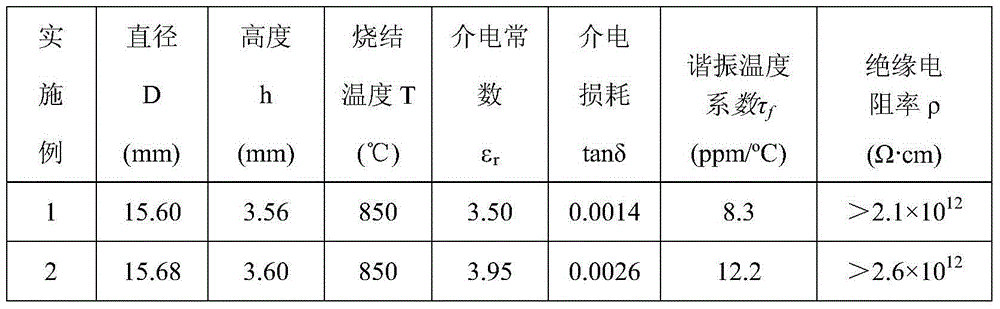

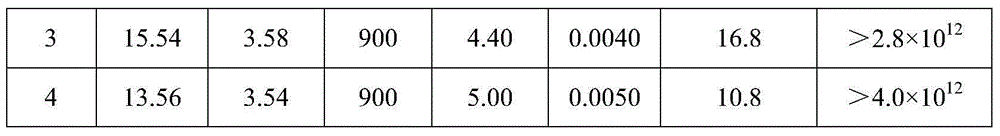

Embodiment 1

[0026] Weigh 37.1g Ca(OH) 2 ; 43.42g H 3 BO 3 ; 6.95g Li 2 CO 3 ; 11.21g La 2 o 3 Mix, add 200g deionized water and 400g zirconia balls, and use wet ball milling for 8 hours;

[0027] After the ball-milled glass raw material is discharged, it is dried at 100°C, then quenched in molten water at 1475°C, and then crushed and ground into glass powder with a particle size of 200μm;

[0028] Weigh 60g prepared glass powder, 10g Al 2 o 3 , 120g SiO2 2 Mix, add 200g deionized water and 400g zirconia balls, use wet ball milling for 10 hours; add 38ml 10wt% PVA polymer binder aqueous solution, ball mill for 4 hours, mix evenly, granulate and press into tablets; The ceramic sheet is heated in a kiln-type sintering furnace at a heating rate of 2 °C / min to 450 °C for 2 hours, and then heated to 650 °C for 2 hours; The cooling rate of °C / min is lowered to 400 °C, and then cooled to room temperature with the furnace to obtain a low dielectric constant microwave dielectric ceramic m...

Embodiment 2

[0030] Weigh 37.5g Ca(OH) 2 ; 44.5 g H 3 BO 3 ;5.5g Li 2 CO 3 ; 11.5g La 2 o 3 Mix, add 200 g of deionized water and 400 g of zirconia balls, and use wet ball milling for 9 hours;

[0031] After the ball-milled glass raw material is discharged, it is dried at 110°C, then quenched in molten water at 1480°C, and then crushed and ground into glass powder with a particle size of 250 μm;

[0032] Weigh 64g prepared glass powder, 14g Al 2 o 3 , 120g SiO 2 Mix, add 360g deionized water and 720g zirconia balls, use wet ball milling for 10 hours; add 36ml 12wt% PVA polymer binder aqueous solution, ball mill for 5 hours, mix evenly, granulate and press into tablets; The ceramic sheet is heated in a kiln-type sintering furnace at a heating rate of 2 °C / min to 450 °C for 2 hours, and then heated to 650 °C for 2 hours; The cooling rate of °C / min is lowered to 400 °C, and then cooled to room temperature with the furnace to obtain a low dielectric constant microwave dielectric cera...

Embodiment 3

[0034] Weigh 38g Ca(OH) 2 ; 45.2 g H 3 BO 3 ; 4.6g Li 2 CO 3 ; 12g La 2 o 3 Mix, add 210g deionized water and 420g zirconia balls, and use wet ball milling for 9 hours;

[0035] After the ball-milled glass raw material is discharged, it is dried at 110°C, then quenched in molten water at 1490°C, and then crushed and ground into glass powder with a particle size of 250 μm;

[0036] Weigh 70g prepared glass powder, 18g Al 2 o 3 , 100g SiO 2Mix, add 200g deionized water and 400g zirconia balls, use wet ball milling for 11 hours; add 37.6ml 14wt% PVA polymer binder aqueous solution, ball mill for 6 hours, mix evenly, granulate and press into tablets; The ceramic pieces were heated in a kiln-type sintering furnace at a heating rate of 2 °C / min to 450 °C for 2 hours, and then heated to 650 °C for 2 hours; at a heating rate of 3 °C / min to 900 °C for 30 min, and then Cool down to 400°C at a cooling rate of 3°C / min, and cool down to room temperature with the furnace to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com