Preparation method of titanium dioxide and grapheme composite nanomaterial

A graphene composite and nanomaterial technology, applied in the field of nanomaterials, to avoid multi-step operations, controllable size, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

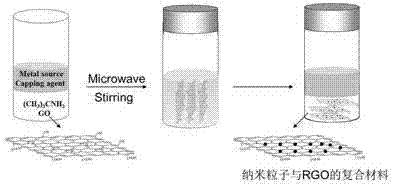

[0021] (~2.5nm)TiO 2 Preparation of graphene composite nanomaterials: Add 5mL GO aqueous solution into a 30mL quartz microwave tube, then add 0.05mL tert-butylamine, and shake evenly. Next, pre-mix 0.075g (0.25mmol) of n-propyl titanate, 0.5mL oleic acid and 5mL toluene in the test tube, add them to the above-mentioned quartz microwave tube, add a magnetic stirrer, seal the quartz tube, Put it into a microwave instrument, set at 150°C, and react for 3h. After the reaction, the quartz microwave tube was naturally cooled to room temperature in a microwave instrument and then taken out. Centrifuge the upper organic phase at a rate of 8000rpm, and the obtained precipitate is TiO 2 Graphene composite nanomaterials.

Embodiment 2

[0023] (~6.7nm)TiO 2 Preparation of graphene composite nanomaterials: Add 5mL GO aqueous solution into a 30mL quartz microwave tube, then add 0.05mL tert-butylamine, and shake evenly. Next, pre-mix 0.075g (0.25mmol) of n-propyl titanate, 0.5mL oleic acid and 5mL toluene in the test tube, add them to the above-mentioned quartz microwave tube, add a magnetic stirrer, seal the quartz tube, Put it into a microwave instrument, set at 150°C, and react for 6h. After the reaction, the quartz microwave tube was naturally cooled to room temperature in a microwave instrument and then taken out. Centrifuge the upper organic phase at a rate of 8000rpm, and the obtained precipitate is TiO 2 Graphene composite nanomaterials.

Embodiment 3

[0025] (~8.4nm)TiO 2 Preparation of graphene composite nanomaterials: Add 5mL GO aqueous solution into a 30mL quartz microwave tube, then add 0.05mL tert-butylamine, and shake evenly. Next, pre-mix 0.075g (0.25mmol) of n-propyl titanate, 0.5mL oleic acid and 5mL toluene in the test tube, add them to the above-mentioned quartz microwave tube, add a magnetic stirrer, seal the quartz tube, Put it into a microwave instrument, set at 150°C, and react for 9 hours. After the reaction, the quartz microwave tube was naturally cooled to room temperature in a microwave instrument and then taken out. Centrifuge the upper organic phase at a rate of 8000rpm, and the obtained precipitate is TiO 2 Graphene composite nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com