Catalyst for synthesis of vinyl acetate by acetylene method and synthetic method of vinyl acetate

A vinyl acetate and catalyst technology, which is applied in the field of acetylene gas phase vinyl acetate catalyst, can solve the problem of low catalyst activity, achieve the effects of improving catalyst activity, improving electronic structure, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of carbon-deposited silicon carbide carrier

[0030] (a) The BET specific surface area, pore volume and particle size are selected to be 35 m 2 / g, 0.33cm 3 / g and 650 μm silicon carbide particles as the substrate, the mixed gas of ethane and argon (the molar ratio of ethane to argon = 1:9) was heated at 850 °C, 1.2 atm and the carbon source volume space velocity was 150 h -1 Under reaction conditions, the carrier precursor A is obtained by passing 100 g of the above-mentioned silicon carbide particles for 3 h;

[0031] (b) Carrier precursor A was calcined at 400 °C in air for 2 h to obtain carrier precursor B;

[0032] (c) Under the condition of 120°C, 200 ml carrier precursor B was immersed in 60% nitric acid aqueous solution for 6 h to obtain carrier precursor C;

[0033] (d) Take 15.0 g of polyvinyl alcohol (the degree of polymerization is 1700, and the degree of alcoholysis is 88%), add it to 85.0 g of boiling pure water, stir to obtain a viscous...

Embodiment 2

[0051] [Example 2] to [Example 6]

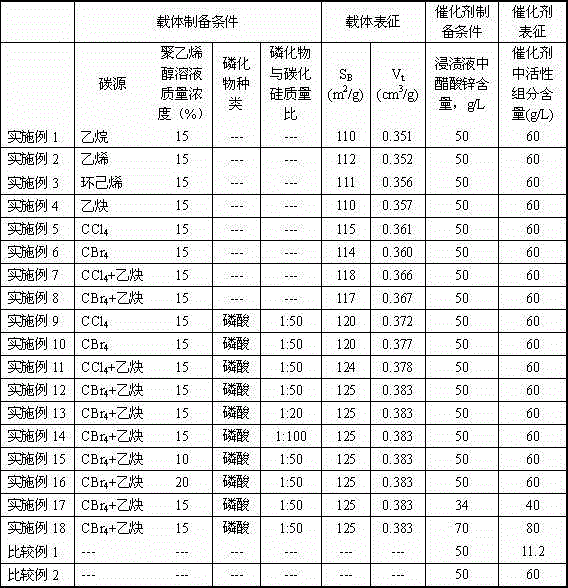

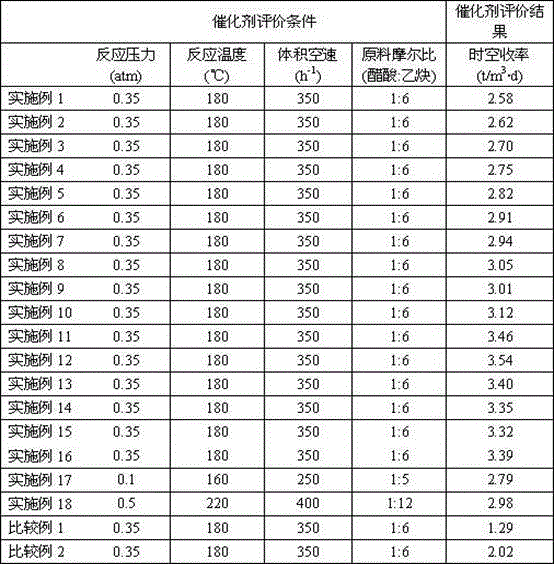

[0052] Except for changing the carbon source in the preparation process of the carbon-deposited silicon carbide carrier, other carrier preparation, catalyst preparation process and catalyst evaluation conditions are the same as in Example 1. For the convenience of comparison, the preparation conditions and characterization of the carrier and catalyst are listed in Table 1, and the evaluation conditions and results of the catalyst are listed in Table 2.

Embodiment 7

[0054] (1) Preparation of carbon-deposited silicon carbide carrier

[0055] (a) The BET specific surface area, pore volume and particle size are selected to be 35 m 2 / g, 0.33cm 3 / g and 650μm silicon carbide particles as the substrate, the CCl 4 , mixed gas of acetylene and argon (CCl 4 , acetylene to argon molar ratio = 1:1:18) at 850°C, 1.2 atm and carbon source volume space velocity 150 h -1 Under reaction conditions, the carrier precursor A is obtained by passing 100 g of the above-mentioned silicon carbide particles for 3 h;

[0056] (b) Carrier precursor A was calcined at 400 °C in air for 2 h to obtain carrier precursor B;

[0057] (c) Under the condition of 120°C, 200 ml carrier precursor B was immersed in 60% nitric acid aqueous solution for 6 h to obtain carrier precursor C;

[0058] (d) Take 15.0 g of polyvinyl alcohol (the degree of polymerization is 1700, and the degree of alcoholysis is 88%), add it to 85.0 g of boiling pure water, stir to obtain a viscous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com