Traditional Chinese medicine ultramicro wall-breaking fine powder for treating stomach disease

A technology of ultra-fine wall breaking and fine powder, which is applied in powder delivery, drug combination, pharmaceutical formulation, etc., and can solve the problems of low content of active ingredients, low dissolution rate, and influence on therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

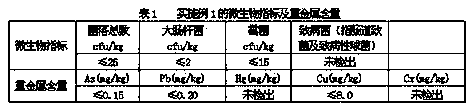

Embodiment 1

[0026] 1) Raw material processing: Weigh 20% white lentils, 15% dry squid ink sac powder, 27% fried jujube seed powder, 12% roasted licorice, 12% atractylodes 12%, and dried tangerine peel 14% according to the weight percentage. After mixing the roasted licorice, atractylodes, and tangerine peel, pulverize with a grinder, pass through a 30-mesh sieve, add dried squid ink sac powder and fried jujube seed powder to mix;

[0027] 2) Broken wall pulverization: the mixed dry powder in step 1) is pulverized to 50μm by an ultrafine grinder to obtain broken wall fine powder;

[0028] 3) Wet ball mill pulverization: Add the fine powder obtained in step 2) into a ball mill for wet ball mill pulverization. The weight ratio of fine powder raw material to water is 1:3, and the speed of the ball mill is 200 rpm. After 2 hours of ball milling, the wall is broken to obtain a ball mill Broken powder

[0029] 4) Add the ball mill broken wall powder in step 3) and soak in water 5 times the weight of t...

Embodiment 2

[0033] 1) Raw material processing: Weigh 30% white lentils, 20% dried squid ink sac powder, 20% fried jujube seed powder, 9% roasted licorice, 9% atractylodes, and 12% tangerine peel according to the weight percentage. After mixing the roasted licorice, atractylodes, and tangerine peel, pulverize with a pulverizer, pass through a 50-mesh sieve, add dried squid ink sac powder and fried jujube seed powder to mix;

[0034] 2) Broken wall pulverization: The mixed dry powder in step 1) is pulverized to 100μm by an ultrafine pulverizer to obtain broken wall fine powder;

[0035] 3) Wet ball mill pulverization: Add the fine powder obtained in step 2) into the ball mill for wet ball mill pulverization. The weight ratio of the fine powder raw material to water is 1:5, the speed of the ball mill is 300 rpm, and the wall is broken after 3 hours of ball milling to obtain a ball mill Broken powder

[0036] 4) Add the ball milled wall powder in step 3) to 6 times the weight of the raw material an...

Embodiment 3

[0040] 1) Raw material processing: weigh 25% white lentils, 17% dried squid ink sac powder, 24% fried jujube seed powder, 10% roasted licorice, 11% atractylodes, and dried tangerine peel 13% according to the weight percentage. After mixing the roasted licorice, atractylodes and tangerine peel, pulverize with a pulverizer, pass through a 30-50 mesh sieve, add dried squid ink sac powder and fried jujube seed powder to mix;

[0041] 2) Broken wall pulverization: the mixed dry powder in step 1) is pulverized to 80 μm by an ultrafine pulverizer to obtain broken wall fine powder;

[0042] 3) Wet ball mill pulverization: Add the fine powder obtained in step 2) to a ball mill for wet ball mill pulverization. The weight ratio of the fine powder raw material to water is 1:4, the speed of the ball mill is 250 rpm, and the wall is broken after 2.5 hours of ball milling to obtain a ball mill Broken powder

[0043] 4) Add the ball mill broken wall powder in step 3) to water 5.5 times the weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com