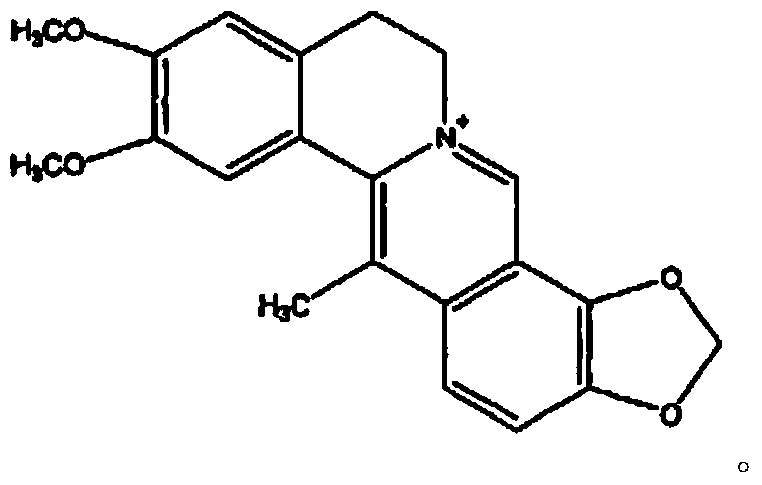

Dehydrocavidine-containing pharmaceutical composition and preparation method thereof

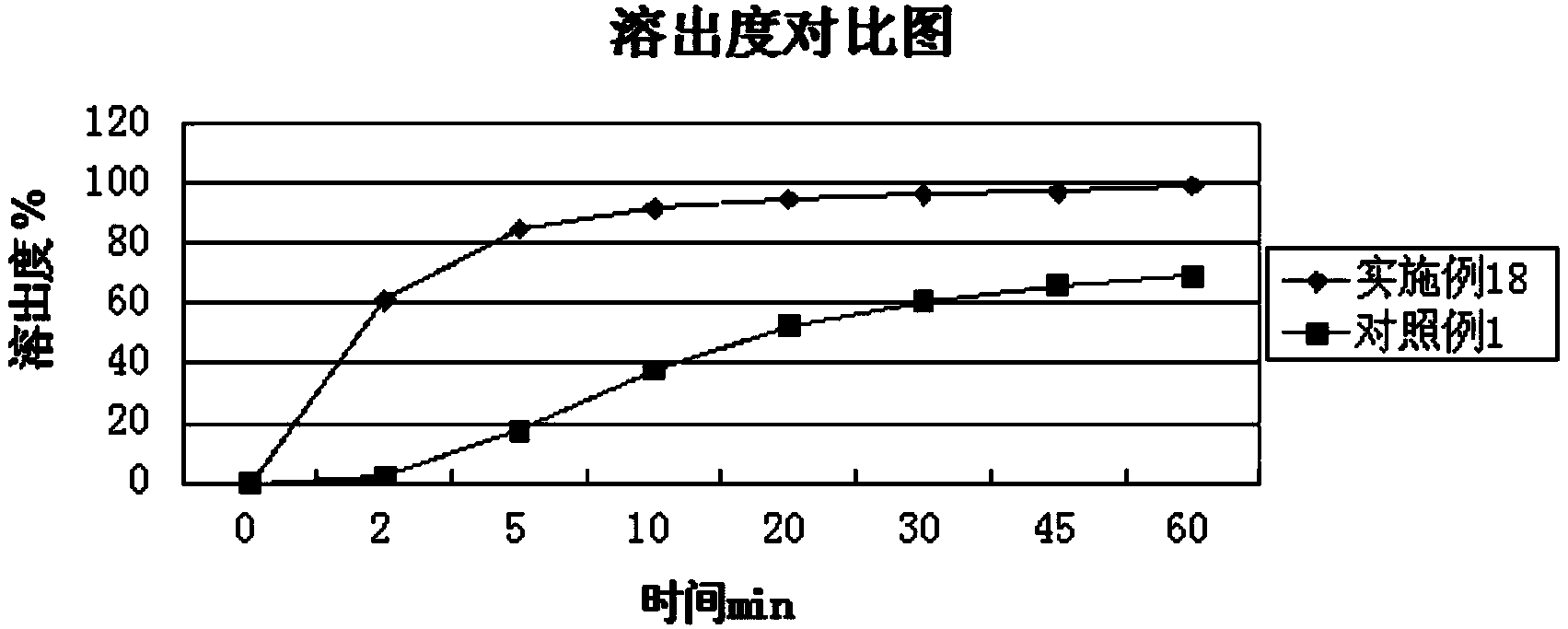

A technology for dehydrocarbudine and a composition is applied in the directions of medical preparations containing active ingredients, medical preparations with non-active ingredients, pharmaceutical formulas, etc. Slow disintegration, slow dissolution rate and other problems, to achieve the effects of good stability and portability, good compliance, and improved dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

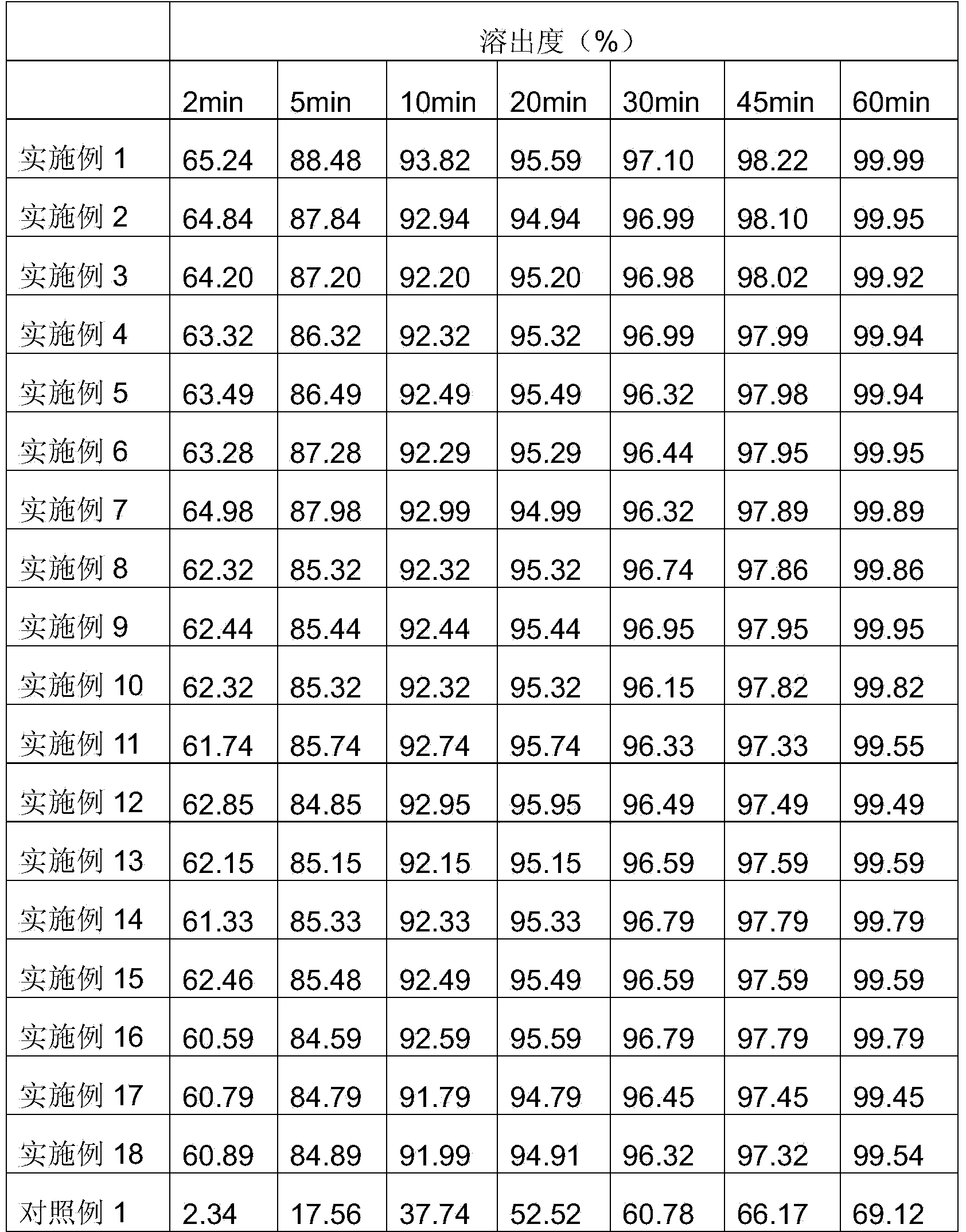

Examples

Embodiment 1

[0049] Weigh 5 mg of dehydrocarvetin, 15 mg of precross-linked starch, 10 mg of microcrystalline cellulose, 0.1 mg of sodium lauryl sulfate, 5 mg of crospovidone, 1 mg of croscarmellose sodium, and appropriate amount of flavoring agent, pass through 80 mesh sieve, mix evenly, add dropwise 5% polyvinylpyrrolidone aqueous solution to make soft material, pass through 24 mesh sieve to granulate, dry the granules at 45-80℃, the moisture reaches 0.5-10%, granulate, add Magnesium stearate 0.1 mg, mixed evenly, compressed into tablets.

Embodiment 2

[0051] Weigh 5 mg of dehydrocarvetin, 15 mg of precross-linked starch, 10 mg of microcrystalline cellulose, 0.1 mg of sodium lauryl sulfate, 5 mg of crospovidone, 1 mg of croscarmellose sodium, and appropriate amount of flavoring agent, pass through 80 mesh sieve, mix evenly, add dropwise 5% polyvinylpyrrolidone aqueous solution to make soft material, pass through 24 mesh sieve to granulate, dry the granules at 45-80℃, the moisture reaches 0.5-10%, granulate, add Micropowder silica gel 0.1mg, mixed evenly, compressed into tablets.

Embodiment 3

[0053] Weigh 25 mg of dehydrocarvetin, 15 mg of precrossed starch, 50 mg of lactose, 0.5 mg of sodium lauryl sulfate, 5 mg of crospovidone, 10 mg of croscarmellose sodium, appropriate amount of flavoring agent, over 80 mesh sieve, mix evenly, add dropwise 5% polyvinylpyrrolidone aqueous solution to make soft material, pass through 24 mesh sieve to granulate, dry the granules at 45-80℃, the moisture reaches 0.5-10%, granulate, add stearic acid Magnesium 1.2mg, mixed evenly, tableted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com