Rapid fresh and wet grain drying method and device

A fast-drying, fresh-wet technology, applied in the direction of drying and preserving seeds, food processing, etc., can solve the problems of slow drying speed, backward technology, failure to solve the time and quality of grain drying, and achieve the effect of fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

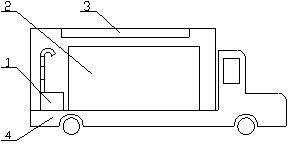

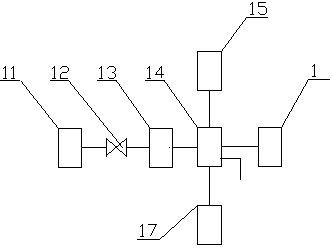

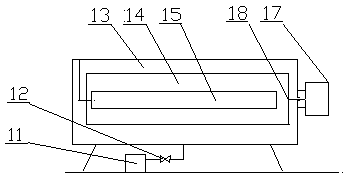

[0023] Embodiment 1, the present embodiment is a kind of method that the fresh wet grain harvested from the field is carried out rapid drying in harvest season, and this method adopts such as image 3 Combined drying unit shown.

[0024] Work steps:

[0025] 1. Firstly, the harvested fresh and wet grains are sorted by the wool grain selector 1 to remove impurities such as broken grasses, reptiles, flat grains, etc., and the sorted good grains are sent into the grain container 14, and the grain container is closed. The door of 14 is to stop grain from leaking out, closes the airtight door of vacuum box 13 simultaneously. According to needs, the grain of adorning in grain container 14 is only just passable about 1 / 3rd of adorned volume.

[0026] 2. Open valve 12.

[0027] 3. Start the vacuum pump 11 and the low-speed device 17, pump the vacuum box 13 into a high vacuum with an air pressure below 500 Pa and maintain the pressure all the time, and at the same time, the rotatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com