Smoke machine

A fog machine and engine technology, applied in the field of fog machines, can solve problems such as overheating and reduced spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

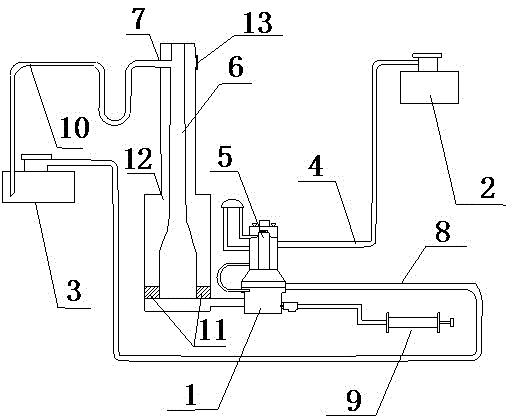

[0016] A fog machine provided in this embodiment, such as figure 1 Shown, comprise engine 1, carburetor 5, spray pipe 6, starting air source, fuel tank 2 and drug tank 3; The combustion chamber of 1 is exhausted through the nozzle 6, and the side of the nozzle 6 away from the end of the engine 1 is provided with a spray nozzle 7, and the spray nozzle 7 communicates with the medicine box 3 through the medicine pipeline 10; the medicine pipeline 10 is provided with a valve ( Not shown in the figure); the combustion chamber of the engine 1 is communicated with the medicine box 3 through an exhaust gas pipeline 8; the combustion chamber of the engine 1 is connected with the starting gas source through a one-way valve; It communicates with the cooling chamber 12 through a filter device 11; the filter device 11 includes a three-way catalyst layer, an asbestos fiber net, and a sound-absorbing cotton layer fixed between two layers of stainless steel mesh; the three-way catalyst layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com