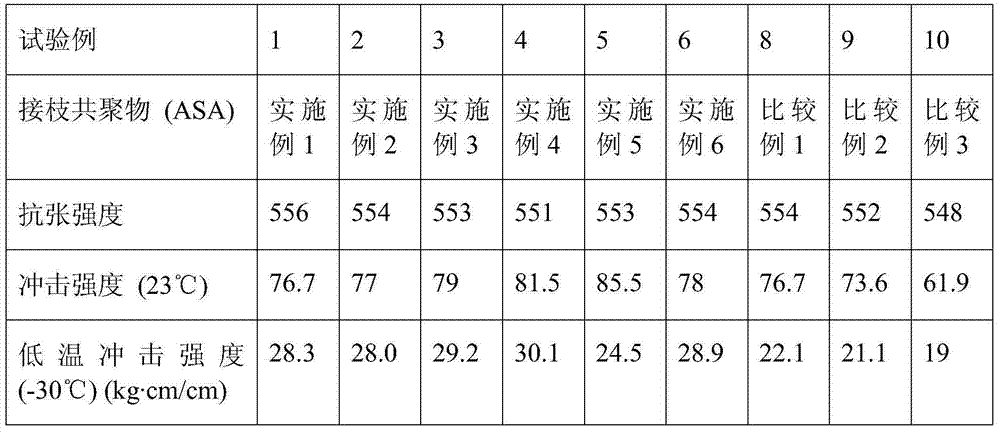

Alkyl acrylate-vinyl aromatic compound-vinyl cyanide compound copolymer having improved low temperature impact strength, and polycarbonate composition comprising same

A technology of alkyl acrylate and aromatic vinyl, which is applied in the field of copolymers, can solve the problems of deterioration of tensile strength and achieve excellent impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The method for preparing the above-mentioned alkyl acrylate-aromatic vinyl compound-vinyl cyanide compound copolymer according to the embodiment includes: relative to 100 parts by weight of All the monomers of the cyanide compound copolymer, (a) make containing 4 to 30 parts by weight of monomers selected from at least one of aromatic vinyl compounds, vinyl cyanide compounds and alkyl acrylates, 0.001 to 1 parts by weight The monomer mixture polymerization of the electrolyte, the crosslinking agent of 0.01 to 1 weight part, the grafting agent of 0.01 to 3 weight parts, the initiator of 0.01 to 3 weight parts and the emulsifier of 0.01 to 5 weight parts prepares seed; ( b) In the presence of the seed, make an alkyl acrylate monomer comprising 20 to 80 parts by weight, a polyalkylene crosslinking agent of 0.01 to 3 parts by weight, an initiator of 0.01 to 3 parts by weight and 0.01 polymerizing a monomer mixture of up to 5 parts by weight of an emulsifier to prepare a rub...

Embodiment 1

[0068] Preparation of hard polymer seeds

[0069] Add 40 parts by weight of distilled water into the polymerization reactor replaced by nitrogen, raise the temperature of the reactor to 75°C, add 0.025 parts by weight of potassium persulfate in batches to initiate the reaction, and then continuously add to it at 75°C Add 5 parts by weight styrene, 0.05 parts by weight Na 2 CO 3 , 0.025 parts by weight of ethylene glycol dimethacrylate, 0.025 parts by weight of allyl methacrylate and 0.05 parts by weight of sodium lauryl sulfate, to prepare hard polymer seeds with an average particle size of 0.1 μm.

[0070] Preparation of Rubbery Polymer Cores

[0071]In the presence of the above-prepared hard polymer seed latex, at 75°C, continuously add 60 parts by weight of distilled water, 55 parts by weight of butyl acrylate, 0.3 parts by weight of polyethylene glycol diacrylate (molecular weight: 258), A mixture of 0.3 parts by weight of allyl methacrylate, 0.5 parts by weight of ...

Embodiment 2

[0077] Graft copolymer powder was prepared in the same manner as described in Example 1, except that in the preparation of the rubbery polymer core of Example 1, 0.3 parts by weight of polyethylene glycol dimethacrylic acid was used Esters (molecular weight: 330) were used instead of PEGDA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com