Porous body and method for producing same

A manufacturing method and porous body technology, applied in the manufacture of tools, ceramic products, casting and molding equipment, etc.

Inactive Publication Date: 2014-07-16

TOYOTA JIDOSHA KK

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In addition, in batteries, the separator made of a porous body may be damaged by heat, impact, etc., and it is desired to increase the strength of the separator

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

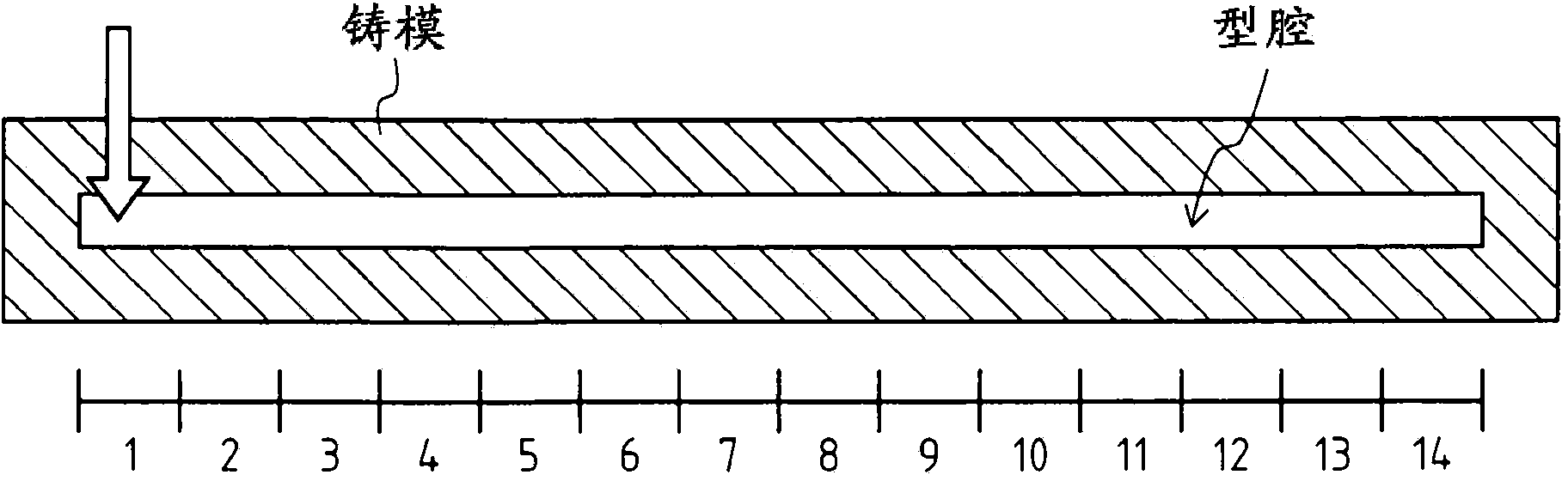

[0073] Experiments were conducted using a casting mold having the same structure as the porous body 1 . No release agent was applied to the molding surface of the mold.

[0074] In this case, the molten metal has reached the right end of the cavity.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Login to View More

Abstract

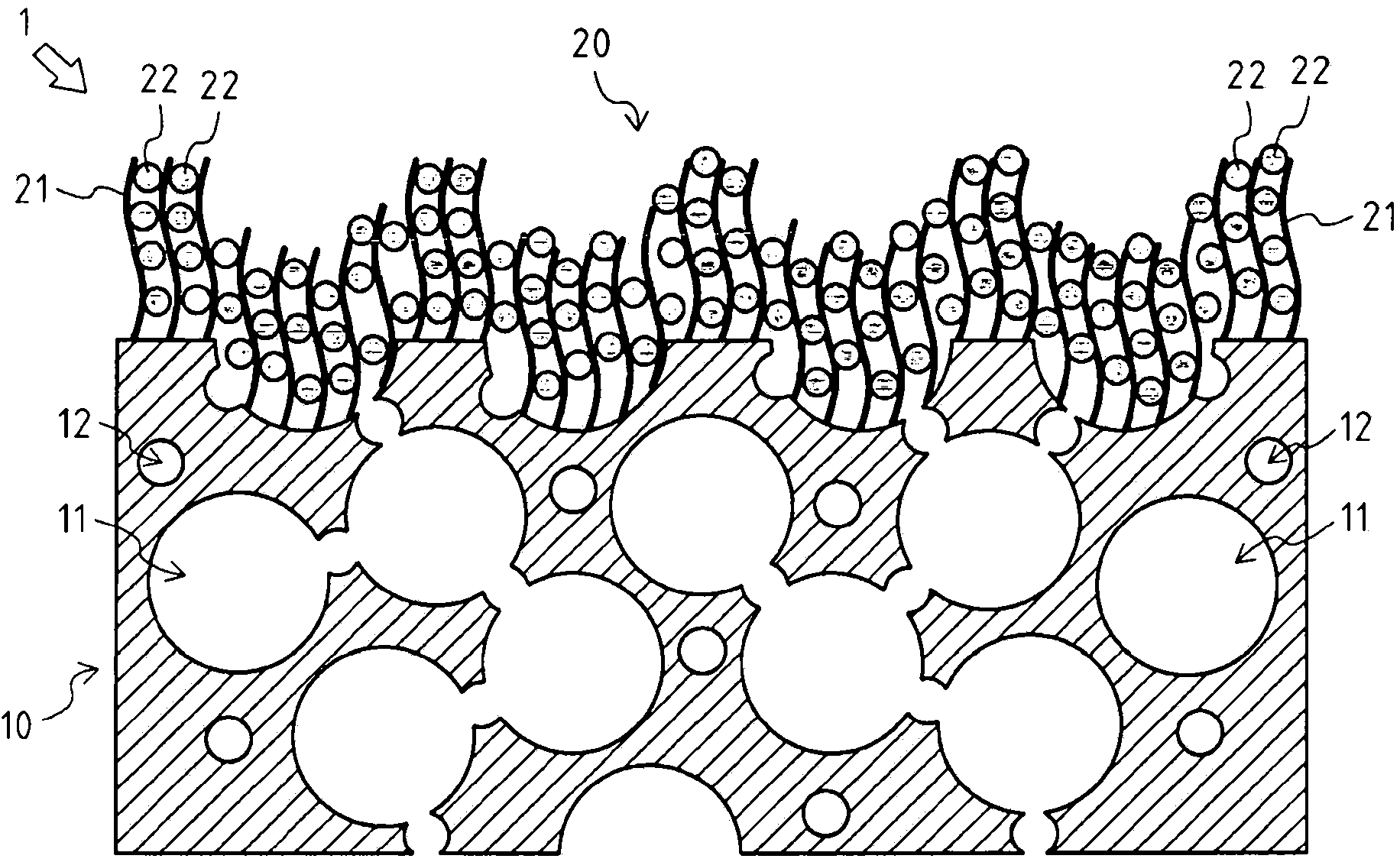

Provided are a high-strength porous body and a method for producing the same. A porous body 1 has a carbon foam body 10, which is a porous material whose primary component is carbon, and a carbon film 20 formed on the surface of the carbon foam body 10, wherein the carbon film 20 comprises multiple microscopic carbon fibers 21 21..., which are fibrous nanocarbons such as carbon nanofibers, carbon nanotubes, carbon nanocoils, or carbon nanofilaments, and multiple fullerenes 22 22..., which are virtually spherical nanocarbons formed from multiple carbon atoms.

Description

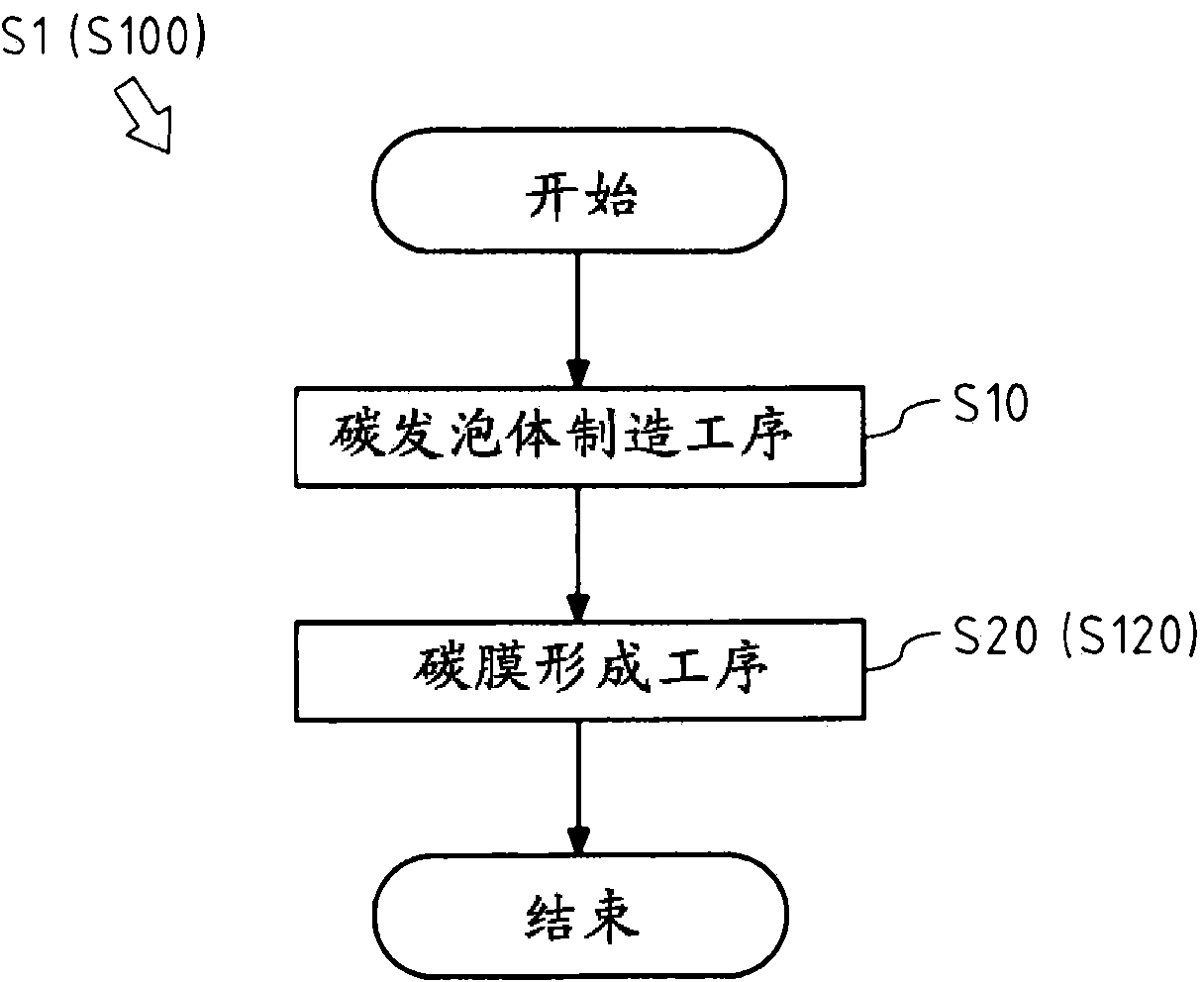

technical field [0001] The present invention relates to a porous body and a manufacturing method thereof. Background technique [0002] Conventionally, porous bodies have been used in casting molds, battery separators, and the like. [0003] Patent Document 1 discloses a casting mold (mold) in which a porous body (porous material) made of metal powder such as stainless steel is used in a part of the cavity. [0004] According to the mold described in Patent Document 1, since the gas in the cavity can be discharged to the outside through the pores of the porous body, casting can be performed well without leaving the gas in the molten metal. [0005] However, the mold disclosed in Patent Document 1 has a problem that the strength is lower than that of the conventional mold due to the porous structure having many pores. For example, during casting, the mold may expand or contract due to the heat of molten metal or the like, and cracks may be generated in the mold accordingly....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B31/02B22C1/00B22C9/06C04B41/85

CPCB22C9/061B22D25/04B29C33/3814B29K2907/04B29L2031/757C04B41/009C04B41/5001C04B41/85C01B32/05Y10T428/249967C04B35/52C04B38/00C04B41/4549C04B41/4596

Inventor 外崎修司古川雄一

Owner TOYOTA JIDOSHA KK

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com