Pole lug single body with embedded composite metal structure, row type pole lug, and manufacturing method of pole lug single body

A composite metal and manufacturing method technology, applied to structural parts, electrical components, circuits, etc., can solve the problems of affecting product appearance, low bonding strength, and high process cost, and achieve low process cost, smooth surface, and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

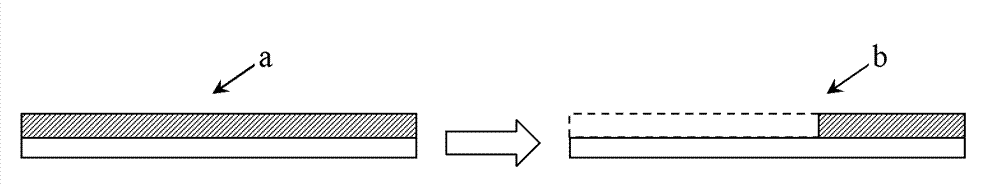

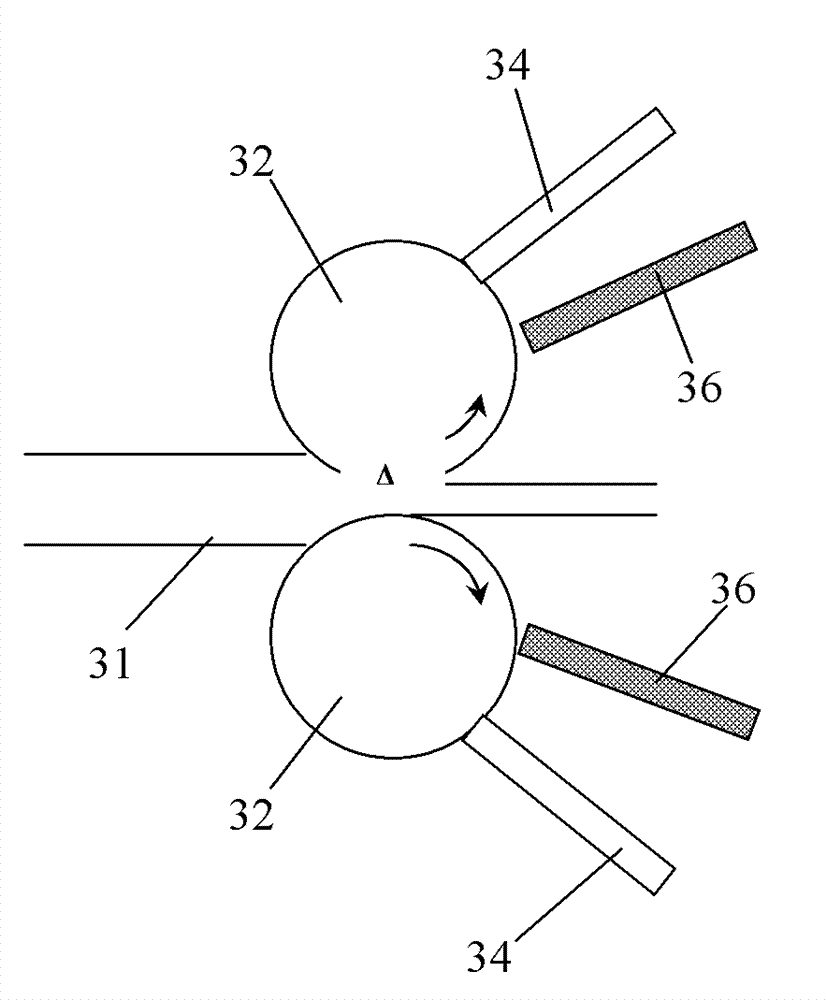

[0046] Example 1: Figure 5 It schematically shows a row-type tab with a transfer-free aluminum-based inlaid nickel composite metal structure, which can be used for lithium-ion batteries. Image 6 Its A-A section structure is shown. like Figure 5 and 6 As shown, this row-type tab consists of a plurality of tab monomers 1 arranged side by side in the width direction and at intervals, and is thermally bonded on the aluminum substrate 11 of the plurality of tab monomers 1 near the easy-to-weld layer 12. The tab glue 2 is made by connecting the plurality of tab monomers 1 into a whole. Wherein, the lug monomer 1 is in the shape of a strip, with a size of 0.1 mm (thickness) × 4 mm (width) × 70 mm (length). The tab monomer 1 includes a strip-shaped aluminum substrate 11 and is arranged The easily weldable portion at one end of the aluminum substrate 11 has recesses 13 on both sides of one end of the aluminum substrate 11. The easily weldable portion is an easily weldable la...

Embodiment 2

[0052] Example 2: A row-type tab with an aluminum-based inlaid copper composite metal structure without transfer welding, which can be used for lithium-ion batteries, and its structure is as follows Figure 5 and 6 As shown, a plurality of lug monomers 1 are arranged side by side in the width direction and at intervals, and the tab glue 2 is thermally bonded to the aluminum substrate 11 of the plurality of tab monomers 1 near the easy-to-weld layer 12. The plurality of lug monomers 1 are connected as a whole. Wherein, the lug monomer 1 is in the shape of a strip, with a size of 0.2 mm (thickness) × 5 mm (width) × 60 mm (length). The lug monomer 1 includes a strip-shaped aluminum substrate 11 and is arranged on The easily weldable portion at one end of the aluminum substrate 11 has recesses 13 on both sides of one end of the aluminum substrate 11. The easily weldable portion is an easily weldable layer (copper layer) 12 that is rolled and bonded to the recess 13. The easil...

Embodiment 3

[0058] Example 3: A row-type tab with an aluminum-based inlaid copper composite metal structure without transfer welding, which can be used for lithium-ion batteries, and its structure is as follows Figure 7 and Figure 8 As shown, a plurality of lug monomers 4 are arranged side by side in the width direction and at intervals, and the tab glue 2 is thermally bonded to the aluminum substrate 41 of the plurality of tab monomers 4 near the easy-to-weld layer 42. The plurality of lug monomers 4 are connected as a whole. Wherein, the lug monomer 4 is in the shape of a strip, with a size of 0.2 mm (thickness) × 5 mm (width) × 120 mm (length). The lug monomer 4 includes a strip-shaped aluminum substrate 41 and is arranged on The easy-to-weld portion in the middle of the aluminum substrate 41 has recesses 43 on both sides of the middle of the aluminum substrate 41, and the easy-to-weld portion is an easy-to-weld layer (copper layer) 42 that is rolled and bonded to the recess 43, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com