Indium Phosphide Wafer Annealing Box

A technology of indium wafers and wafers, which is applied in the field of indium phosphide wafer annealing boxes, can solve the problems of affecting the atmosphere and affecting the annealing effect, so as to solve the problems of inconsistent surface morphology, improve electrical uniformity and surface integrity, and reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

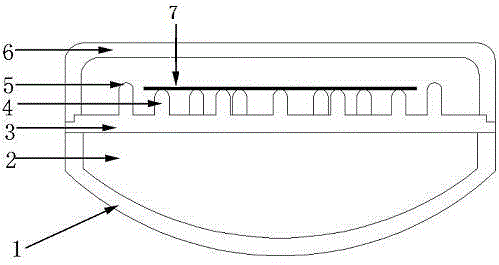

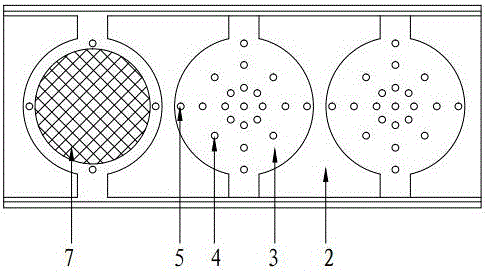

[0015] combined with figure 1 , 2 , to describe the present invention in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0016] The invention specifically relates to an indium phosphide wafer annealing box, which specifically includes a base 1, a material holding chamber 2, a wafer platform 3, a support column 4, a fixing column 5 and a top cover 6, all of which are made of high-purity quartz, wherein the base 1 It is an elongated trough-like structure, or a semicircular chamber, above which is provided a top cover 6 matched with the base 1, and more than one wafer platform 3 is arranged between the top cover 6 and the base 1. The two ends of the wafer platform 3 are supported on the two side walls of the base 1, and the groove between the wafer platform 3 and the base 1 is a storage chamber 2, and the storage chamber 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com