High-strength bolt shear key structure and constructing method thereof

A technology of high-strength bolts and shear keys, which is applied in the direction of building construction, construction, and building materials, can solve problems such as pre-tension relaxation and reduced connection performance of composite structures, and achieve creep reduction and enhanced shear connections Ability and strength, the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

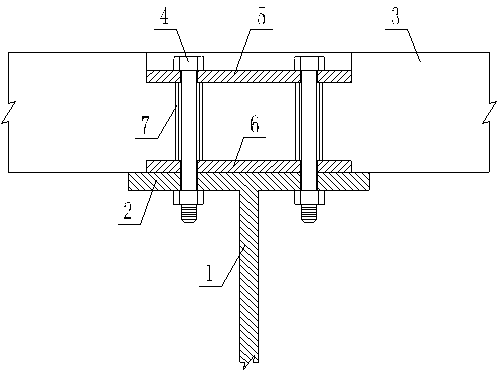

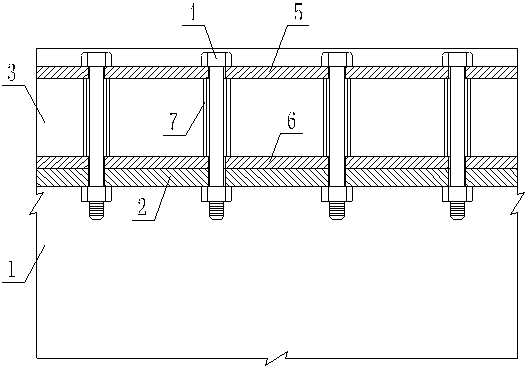

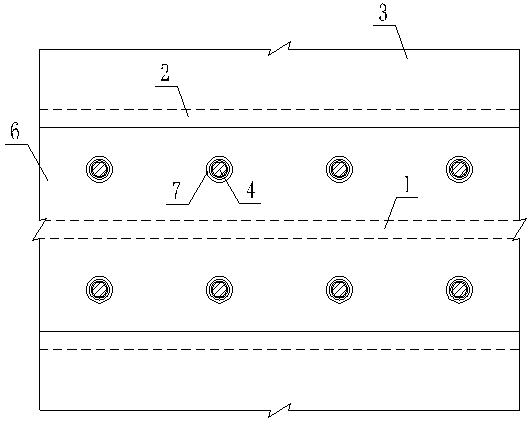

[0014] A high-strength bolt shear key structure, including a steel beam composed of a steel beam web 1 and a steel beam flange 2, a prefabricated concrete slab 3, high-strength bolts 4, and an upper backing plate 5, a lower backing plate 6, and a supporting steel pipe 7 Connectors, the upper and lower ends of the supporting steel pipe 7 are respectively fixed against the upper backing plate 5 and the lower backing plate 6, and the steel beam flange plate 2, the upper backing plate 5 and the lower backing plate 6 are on the axis of the supporting steel pipe 7 All are provided with round holes adapted to the high-strength bolts 4, the inner diameter of the supporting steel pipe 7 is not smaller than the diameter of the above-mentioned round hole, the connecting piece is poured in the precast concrete slab 3, the supporting steel pipe 7 is used as a supporting Most of the high-strength bolts are pre-stressed, so as to reduce the pressure on the concrete, significantly reduce the c...

Embodiment 2

[0017] A construction method for a high-strength bolt shear key structure. Firstly, a steel beam web 1 and a steel beam flange 2 are processed into a steel beam in the form of an I-beam, and a precast concrete slab 3 is manufactured at the same time, and the upper backing plate 5. The connecting piece consisting of the lower backing plate 6 and the supporting steel pipe 7 is poured on the design position of the precast concrete slab, and the supporting steel pipe 7 is sandwiched between the upper backing plate 5 and the lower backing plate 6; then the construction site of the steel beam is completed erection, and then lay the precast concrete slab 3 on the steel beam, and use the supporting steel pipe 7 of the connector as a formwork for drilling; finally, the precast concrete slab 3 and the flange plate 2 of the steel beam are bolted in place until they fit together state, the two are connected by the clamping force of the high-strength bolt 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com