Preparation method of bright black ink for screen printing

A screen printing, bright black technology, applied in the field of printing ink, can solve the problem of ink usage restrictions, and achieve the effect of reducing surface tension, reducing dispersion time, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The bright black ink for screen printing of the present invention contains 20-25 parts by weight of Seiko 1000-800 varnish, 74-76 parts by weight of black pigment, 1.8-2.2 parts of transparent red pigment, and 13.5-14.5 parts by weight transparent blue pigment, 32.0-40.0 parts by weight of acrylic resin, 35.0-42.0 parts by weight of butyl glycidyl ether, 8.0-10.0 parts by weight of epoxy soybean oil, and 75-80 parts by weight of mixed solvent. Wherein, the mixed solvent is composed of n-butanol, n-butyl acetate and acetone; and the n-butanol is 35-40 parts by weight, the n-butyl acetate is 15-20 parts by weight, and the acetone is 15-20 parts by weight . And, the bright black ink is prepared by the following method, and the preparation method comprises the following steps:

[0033] (1) 35.0-42.0 parts by weight of butyl glycidyl ether and 30-35 parts by weight of mixed solvent are fully mixed and dissolved by stirring to prepare a dispersion solution;

[0034] (2) Wit...

Embodiment 1

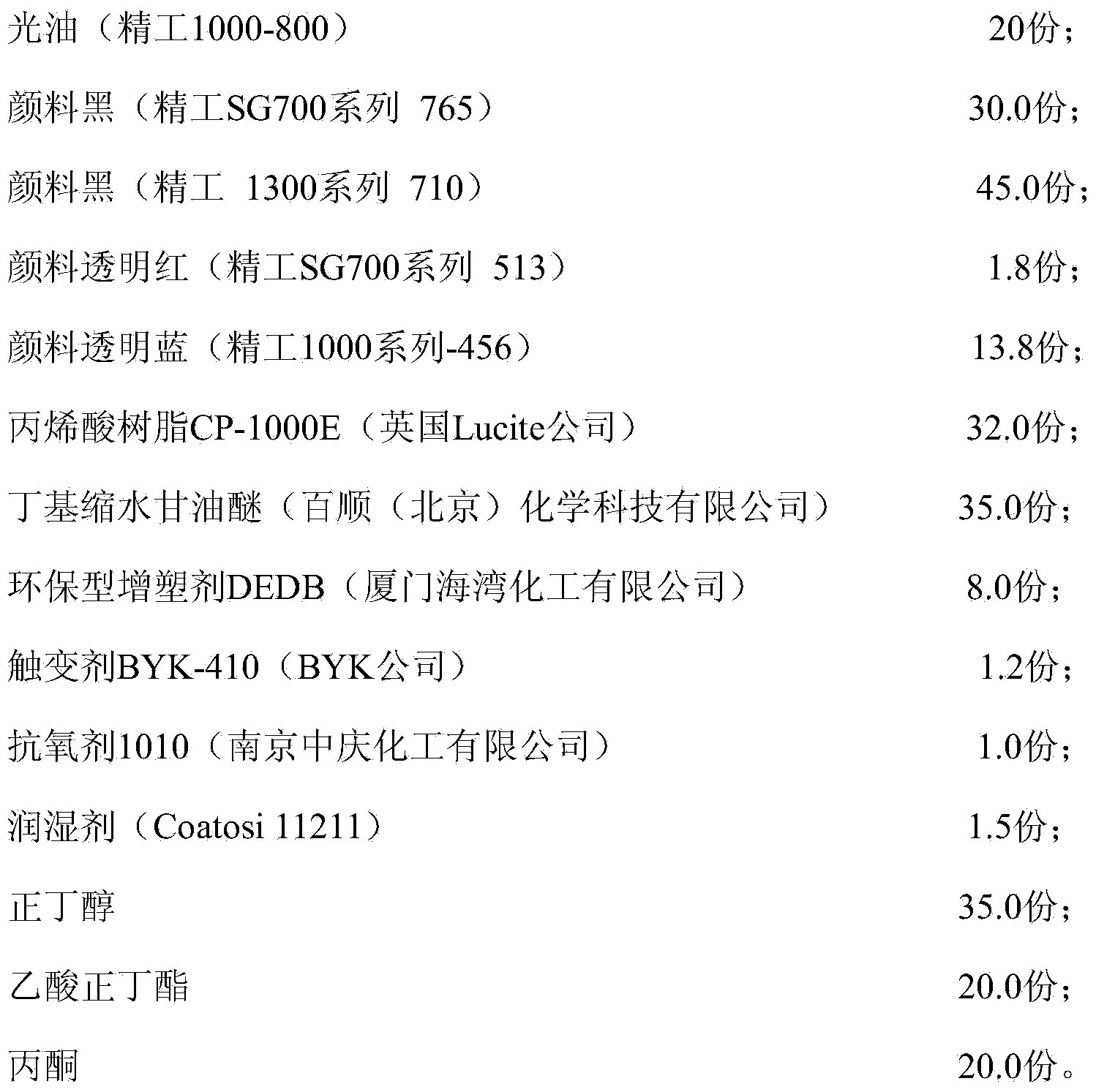

[0039] The bright black ink for screen printing described in the present embodiment contains the following components in parts by weight:

[0040]

[0041] The viscosity of the ink is about 50,000 to 80,000 centipoise; when the color of the plasticized ink is expressed in Lab color mode, the range of L value is 25.95, the range of a value is -0.21, and the range of b value is - 0.22.

Embodiment 2

[0043] The bright black ink for screen printing described in the present embodiment contains the following components in parts by weight:

[0044]

[0045]

[0046] The viscosity of the ink is about 40,000 to 80,000 centipoise; when the color of the plasticized ink is expressed in Lab color mode, the range of L value is 25.95, the range of a value is -0.21, and the range of b value is - 0.22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com