Method for removing sulfide in methyl tertiary butyl ether through double-solvent extractive distillation

A methyl tert-butyl ether, extractive distillation technology, applied in ether separation/purification, ether preparation, organic chemistry and other directions, can solve the problems of high cost, low safety factor and strong corrosiveness of sulfur-containing wastewater, and achieve low sulfur content, no three waste emissions, and the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

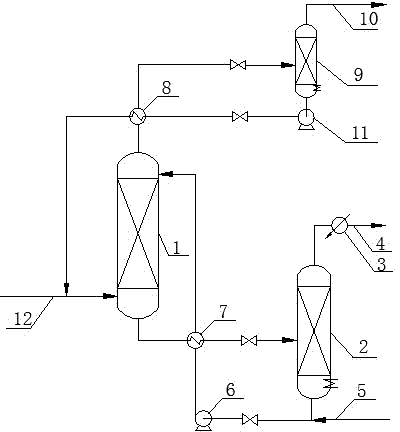

[0018] The sulfur content of MTBE feedstock oil is 129μg / g, and it is used as lubricating oil for organic sulfur extraction agent. First, mix the organic sulfur extractant and MTBE raw material oil at a mass ratio of 0.1, and then enter the column from the lower part of the extraction tower 1 into the tower for countercurrent contact with the MTBE extractant for extraction. The operating conditions of the extraction tower 1 are: pressure 0.21MPa, temperature 20°C , Airspeed 1.0h -1 The composition of MTBE extraction agent is: water 59g, NMP12g, DMF15g, triethylene glycol 5g, sulfolane 4g, n-butanol 5g; MTBE extraction agent and MTBE raw material oil enter extraction tower 1 top with agent oil mass ratio 3.0 countercurrent; MTBE product The operating conditions of distillation column A2 are: pressure 0.10MPa, tower bottom temperature 75°C, tower top temperature 70°C, space velocity 1.1h -1 ; The operating conditions of organic sulfur extraction agent recovery distillation towe...

example 2

[0020] The sulfur content of MTBE feedstock oil is 120μg / g, and the organic sulfur extraction agent uses diesel oil. First mix the organic sulfur extractant and MTBE raw material oil according to the mass ratio of 0.1, and then enter the column from the lower part of the extraction tower 1 to contact and extract the MTBE extractant countercurrently. The operating conditions of the extraction tower 1 are: pressure 0.20MPa, temperature 20°C , Airspeed 1.3h -1 The composition of MTBE extraction agent is: water 63g, NMP11g, DMF15g, triethylene glycol 4g, sulfolane 4g, n-butanol 3g; MTBE extraction agent and MTBE raw material oil enter extraction tower 1 top with agent oil mass ratio 2.0 countercurrent; MTBE product The operating conditions of distillation column A2 are: pressure 0.10MPa, tower bottom temperature 75°C, tower top temperature 70°C, space velocity 1.2h -1 ; The operating conditions of organic sulfur extraction agent recovery distillation tower B9 are: pressure 0.11MP...

example 3

[0022] The sulfur content of MTBE feedstock oil is 137μg / g, and kerosene is used as organic sulfur extraction agent. First, mix the organic sulfur extractant and MTBE raw material oil according to the mass ratio of 0.2, and then enter the tower from the lower part of the extraction tower 1 to contact and extract the MTBE extractant countercurrently. The operating conditions of the extraction tower 1 are: pressure 0.30MPa, temperature 20°C , Airspeed 1.0h -1 The composition of MTBE extraction agent is: water 70g, NMP10g, DMF10g, triethylene glycol 5g, sulfolane 2g, n-butanol 3g; MTBE extraction agent and MTBE raw material oil enter extraction tower 1 top with agent oil mass ratio 3.5 countercurrents; MTBE product The operating conditions of distillation column A2 are: pressure 0.15MPa, tower bottom temperature 75°C, tower top temperature 70°C, space velocity 1.1h -1 ; The operating conditions of organic sulfur extraction agent recovery distillation tower B9 are: pressure 0.15M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com