A prestressed channel grouting agent with self-healing function

A pore grouting and prestressing technology, which is applied in the field of building materials, can solve the problems of lowering the foaming temperature of organic foaming agents, easy cracking of hardened slurry, and uncontrollable foaming expansion, so as to speed up the reaction speed and improve the operability The effect of improving resistance and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

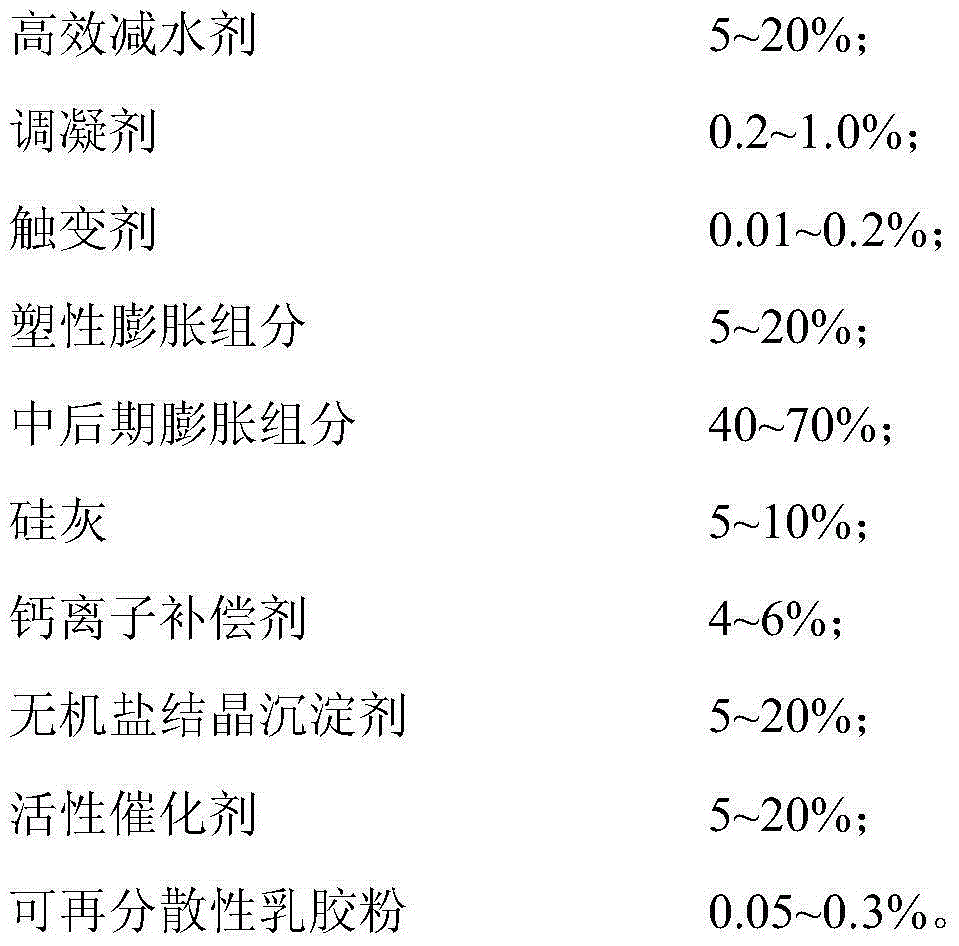

Method used

Image

Examples

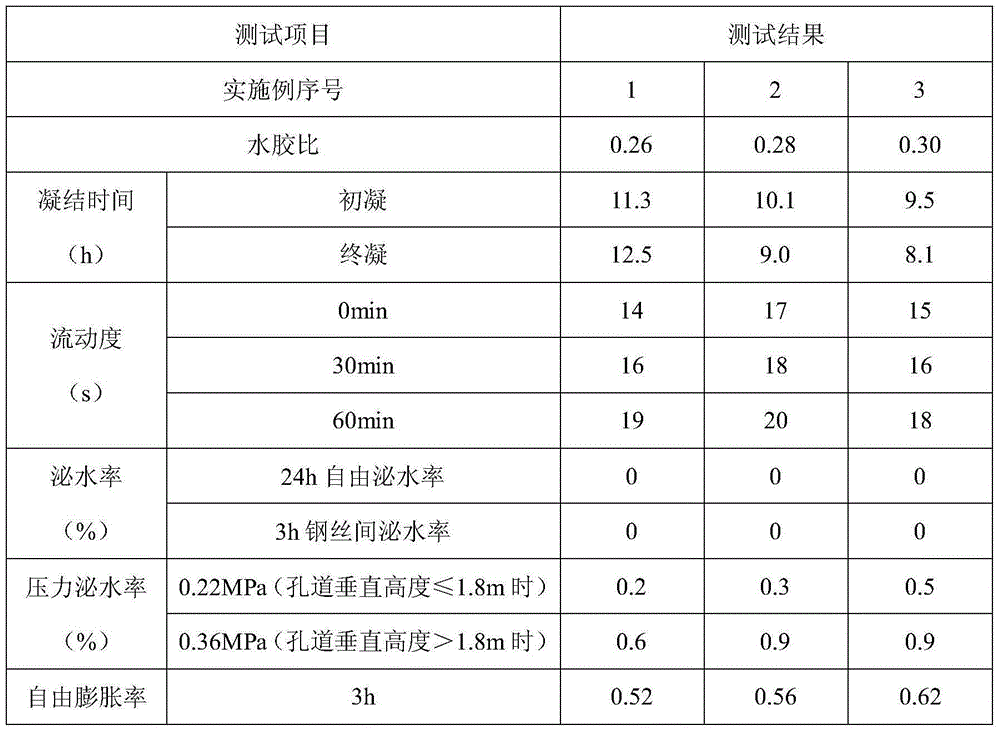

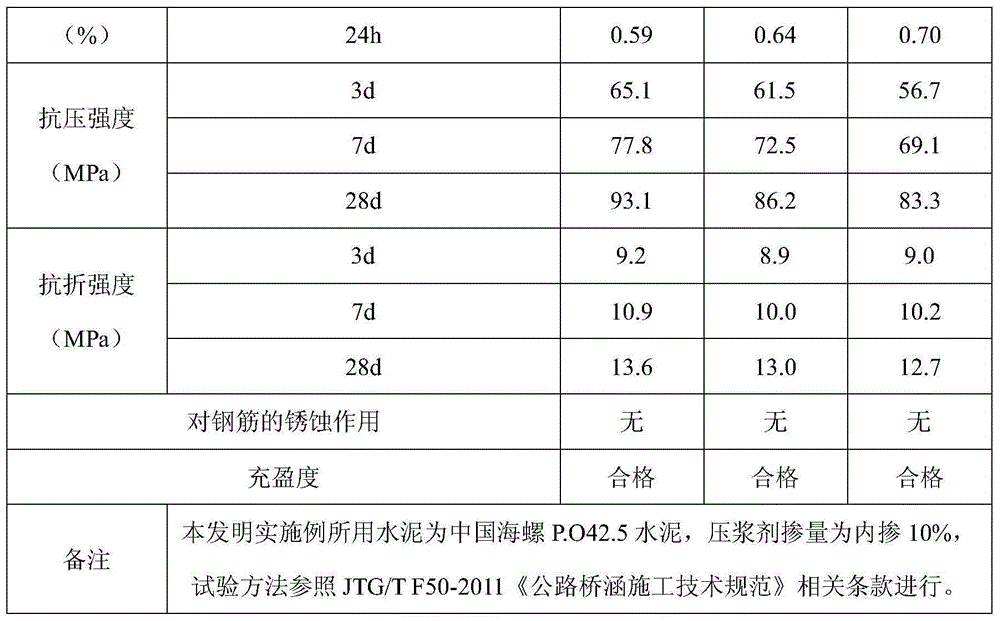

Embodiment 1

[0027] Example 1: A prestressed channel grouting agent with self-repairing function, the weight percentage of each component is: 20% of naphthalene-based high-efficiency water reducer, 0.08% of sodium gluconate, 0.01% of vinylon gum, hydroxypropyl methyl Base cellulose ether 0.02%, N,N-dinitrosopentamethylenetetramine 4%, azodicarbonamide 4%, biuret 2%, calcium sulfoaluminate expansion agent 42.79%, silica fume 5 %, 6% slaked lime, 8% sodium silicate, 0.8% citric acid, 3.2% sodium edetate, 4.0% macrocyclic polyether compound, and 0.1% ethylene-vinyl acetate copolymer. The product of the present invention can be obtained by accurately weighing the weight percentage and uniformly mixing mechanically.

Embodiment 2

[0028] Example 2: A prestressed channel grouting agent with self-repairing function, the weight percentage of each component is: 15% of naphthalene-based high-efficiency water reducer, 0.06% of sodium gluconate, 0.017% of vinylon gum, hydroxypropyl methyl 0.033% cellulose ether, 5.6% N,N-dinitrosopentamethylenetetramine, 5.6% azodicarbonamide, 2.8% biuret, 46.74% calcium sulfoaluminate expansion agent, 7 silica fume %, 5% hydrated lime, 6% sodium silicate, 0.3% citric acid, 1.8% sodium edetate, 3.9% macrocyclic polyether compound, and 0.15% ethylene-vinyl acetate copolymer. The product of the present invention can be obtained by accurately weighing the weight percentage and uniformly mixing mechanically.

Embodiment 3

[0029] Example 3: A prestressed channel grouting agent with self-repairing function, the weight percentage of each component is: 10% naphthalene-based high-efficiency water reducer, 0.04% sodium gluconate, 0.023% vinylon gum, hydroxypropyl methyl 0.047% cellulose ether, 6.4% N,N-dinitrosopentamethylenetetramine, 6.4% azodicarbonamide, 3.2% biuret, 50.69% calcium sulfoaluminate expansion agent, 8 silica fume %, 5% hydrated lime, 5% sodium silicate, 0.15% citric acid, 1.6% sodium edetate, 3.25% macrocyclic polyether compound, and 0.2% ethylene-vinyl acetate copolymer. The product of the present invention can be obtained by accurately weighing the weight percentage and uniformly mixing mechanically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com