Electric heating radiation perforated porous membrane equipment and perforation method

An electric heating and radiation technology, applied in ohmic resistance heating, electric heating devices, metal processing, etc., can solve the problems of skin discomfort, pollution, damage to the flexibility of plastic films, etc., to ensure safety, ensure flexibility, and solve pollution problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

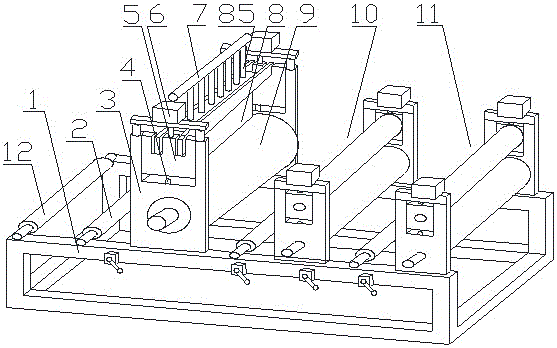

[0020] Embodiment 1: with reference to attached Figure 1-4. An electric heating radiation perforated porous film equipment, including a controller, two guide roller support guide plates 3 relatively fixed on the frame 1, the two ends of the perforated pore forming die roller 9 are installed on the guide roller support guide plate 3 guide In the roller support part, two guide blocks 5 slide up and down with the guide grooves on the two guide roller support guide plates 3 respectively, and the two ends of the electric heating radiating air outlet die head 8 are respectively connected with the guide blocks 5 and the upper end surface of the guide block 5 is connected to the guide block 5. Cylinder 6 piston rod connection. The roll surface of the perforated hole forming mold roll 9 is densely covered with grooves 91 . The shape of the groove 91 is circular, rectangular or irregular. Electric heating radiates out the air outlet of the wind die head 8, and the strip-shaped tuyer...

Embodiment 2

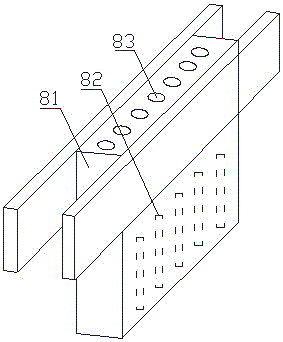

[0021] Embodiment 2: On the basis of Embodiment 1, the electric heating radiating air outlet die head 8 is composed of a hot air radiation cavity 81, an electric heating body 82, and an air duct 7. The upper end of the hot air radiation cavity 81 is provided with a plurality of inlets. The tuyere 83 and a plurality of air inlets 83 communicate with the air duct 7 through the branch air duct 85 respectively, and the air duct 7 communicates with the air source through the air delivery duct. The body 82 is coiled on the body of the hot air radiation chamber 81 and is connected with the electric heating control end of the controller through a wire.

Embodiment 3

[0022] Embodiment 3: On the basis of Embodiment 1 or 2, copper or carbon steel is used for the hot air radiation cavity in the electric heating radiating air outlet die head 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com